Rotating-disk type internal-pushing cup-falling machine

A turntable, drop-cup technology for use in coin-operated equipment for dispensing discrete items, coin-operated equipment for controlled dispensing of fluid/granular materials from containers, instruments, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

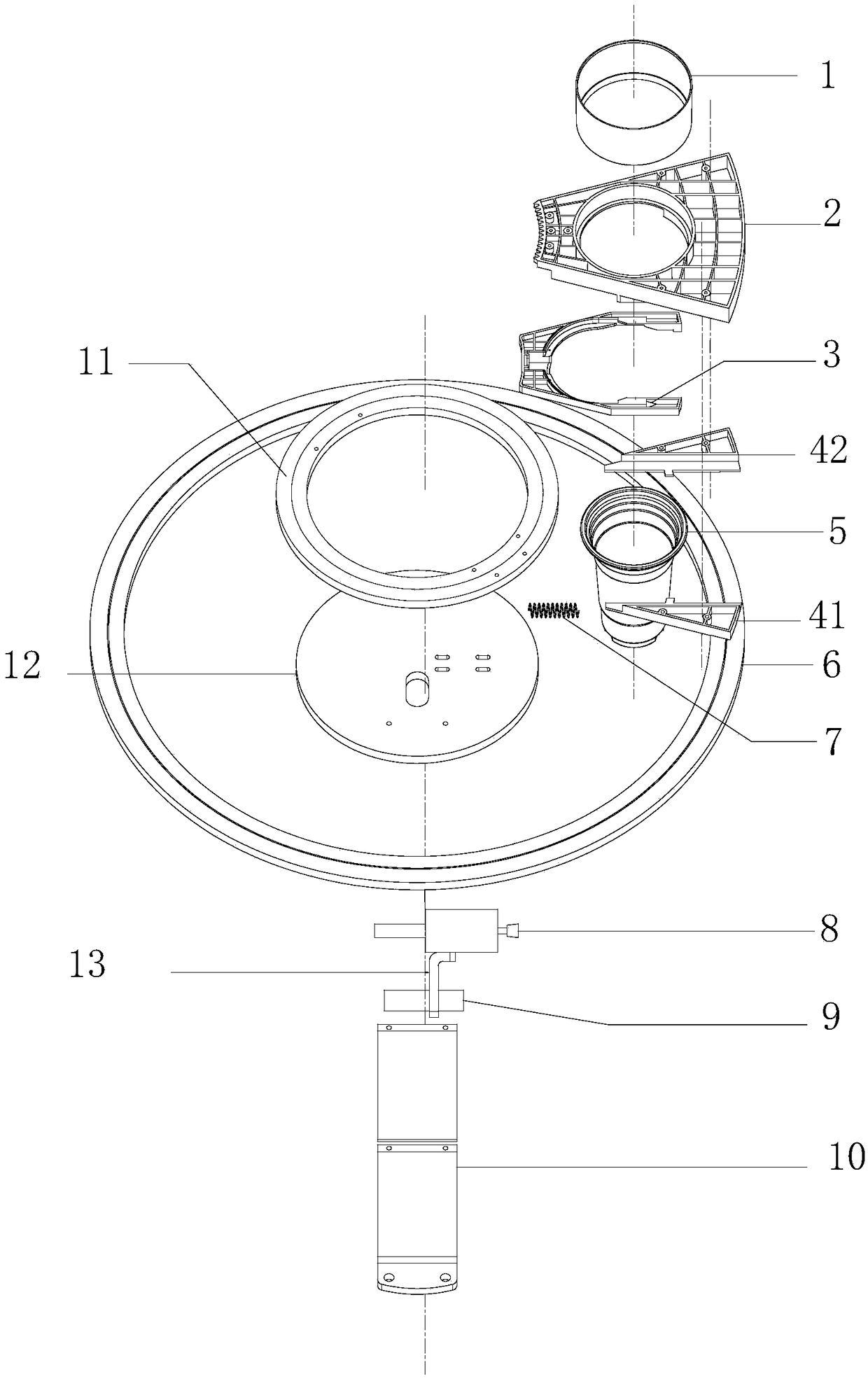

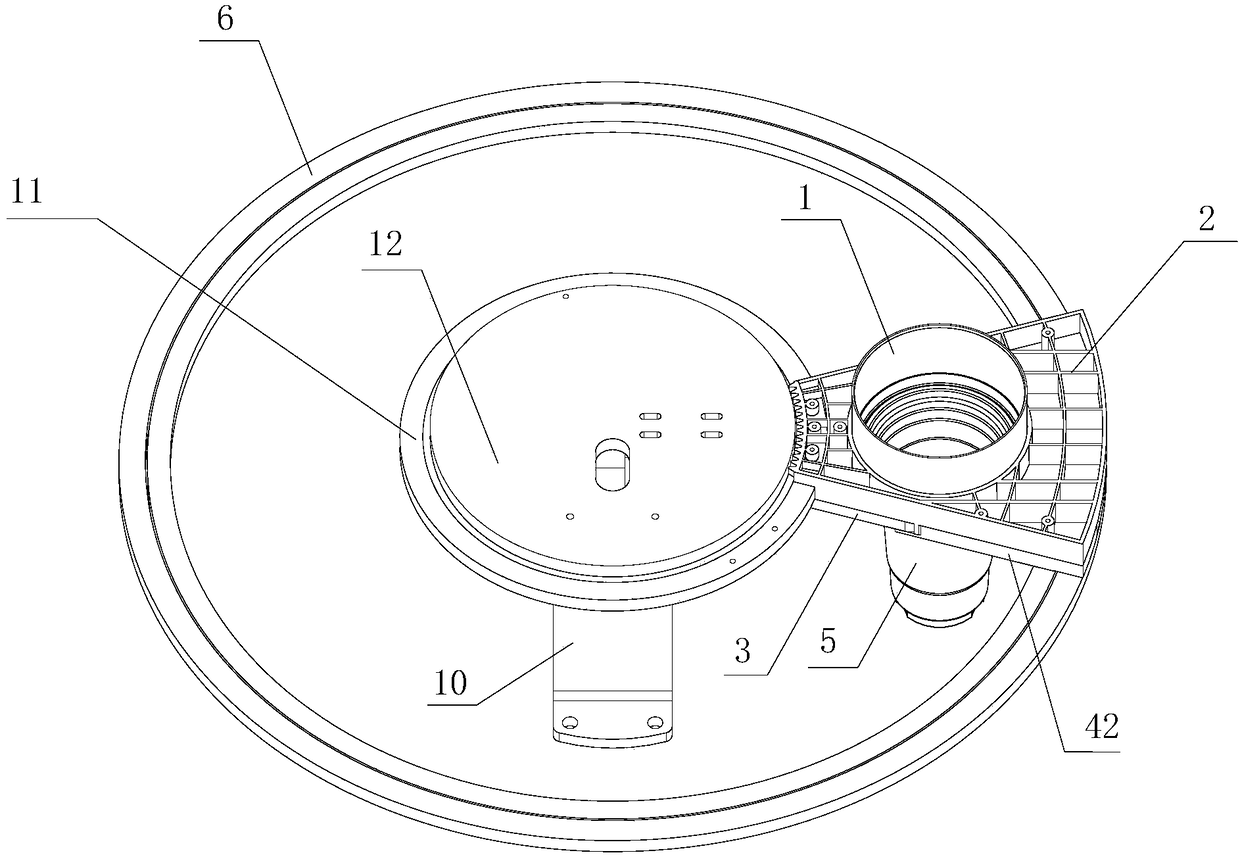

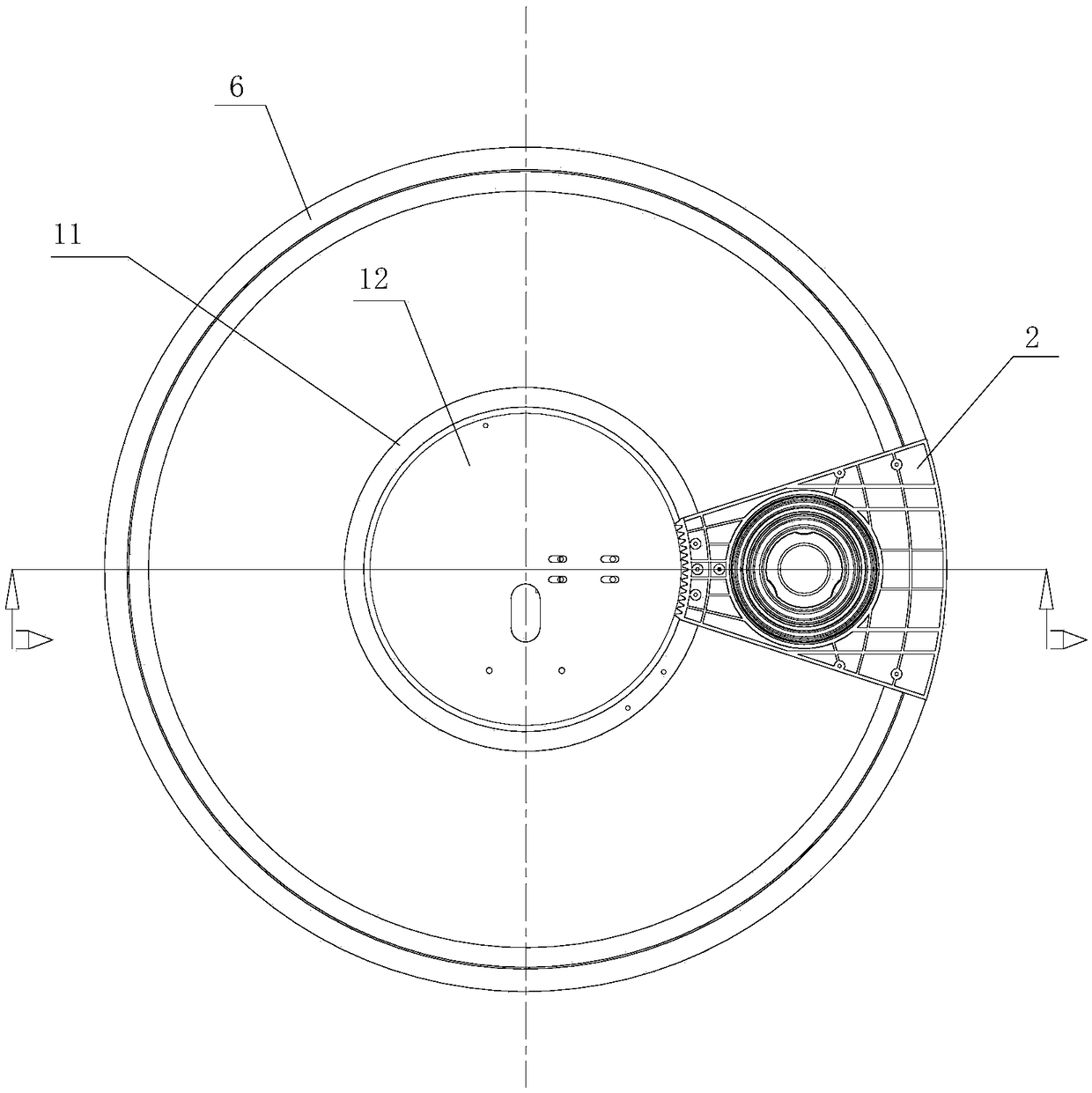

[0040] Embodiment 1: A turntable type internal push cup drop machine provided in this embodiment 1, its structural schematic assembly diagram when used for cup drop is as follows figure 1 As shown, the structural schematic general assembly diagram is shown in figure 2 as shown, figure 2 The schematic top view of the structure is as follows image 3 as shown, figure 2 The main view of the schematic diagram of the structure is as follows Figure 4 as shown, image 3 The A-A sectional view in the Figure 5 As shown, the rotary table-type internal push cup machine includes a bracket 10, a push rod mechanism 8, a turntable installed on the bracket 10, and a cup drop device installed on the turntable. In this embodiment, the turntable type inner push cup machine also includes a turntable mounting plate 12 installed on the bracket 10, the turntable includes an inner turntable 11 and an outer turntable 6 that are slidingly fitted on the turntable set plate 12, and the cup drop...

Embodiment 2

[0057] Embodiment 2: structure is basically the same as Embodiment 1, and the similarity is no longer repeated, and the difference is:

[0058] The turntable-type internal cup-dropping machine provided in this embodiment includes more than two cup-dropping devices installed on the turntable (these cup-dropping devices can be distributed circumferentially on the turntable). The cup drop machine includes more than two cup drop devices installed between the outer turntable 6 and the inner turntable 11. In this embodiment, the details are as follows: Figure 6 As shown, it includes 4 cup drop devices, of course, 6 or 8 can also be configured according to needs; at the same time, there are also devices on the turntable (such as between the outer turntable 6 and the inner turntable 11) for installing milk tea powder, fruit juice powder, etc. The food mounting seat 15 of various food bags is to achieve a more flexible and rich product application range. Under the structural configur...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com