Spherical composite insulator

A composite insulator and spherical technology, which is applied in the field of electric power engineering, can solve the problems of easy ice flashover and service life, and achieve the effect of reducing surface contamination and ice coating, and prolonging the normal working cycle.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

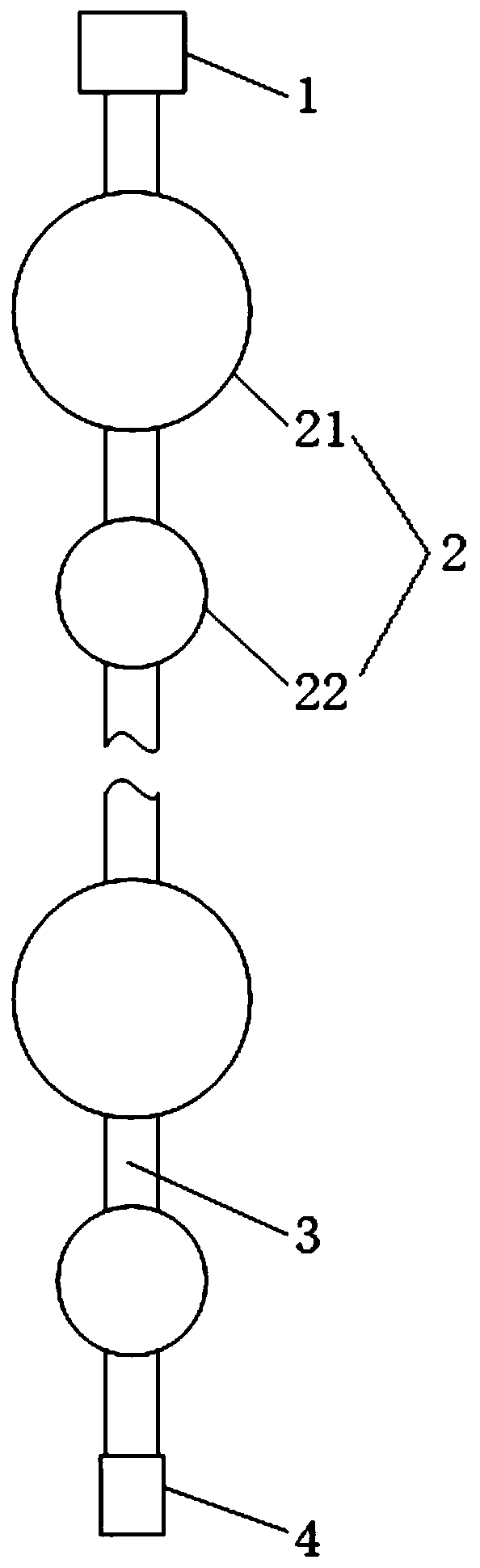

[0024] see figure 1 , the spherical composite insulator shown in the figure is a preferred solution of the present invention, specifically including a ball-socket fitting 1 , a spherical body 2 , a mandrel 3 and a ball-end fitting 4 .

[0025] The mandrel 3 is a glass mandrel, and at least two groups of spherical bodies 2 are arranged on the mandrel 3, and the spherical body with a spherical structure is used to replace the existing shed insulator, and the centers of all the spherical bodies 2 are located on the axis of the mandrel 3 In this way, it is ensured that the center of gravity of the insulator falls uniformly on the axis of the mandrel 3 .

[0026] The spherical body 2 in this embodiment includes two insulating spheres, one large and one small, wherein the diameter of the first insulating sphere 21 is greater than the diameter of the second insulating sphere 22, and the first insulating sphere 21 is close to the upper end of the mandrel 3, and the second Insulating ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com