Preformed armor rod mounting winder

A pre-twisted wire and winder technology, applied in the direction of overhead lines/cable equipment, etc., can solve problems such as difficulties in the installation process, and achieve the effect of convenient operation, free application, and extremely easy to use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

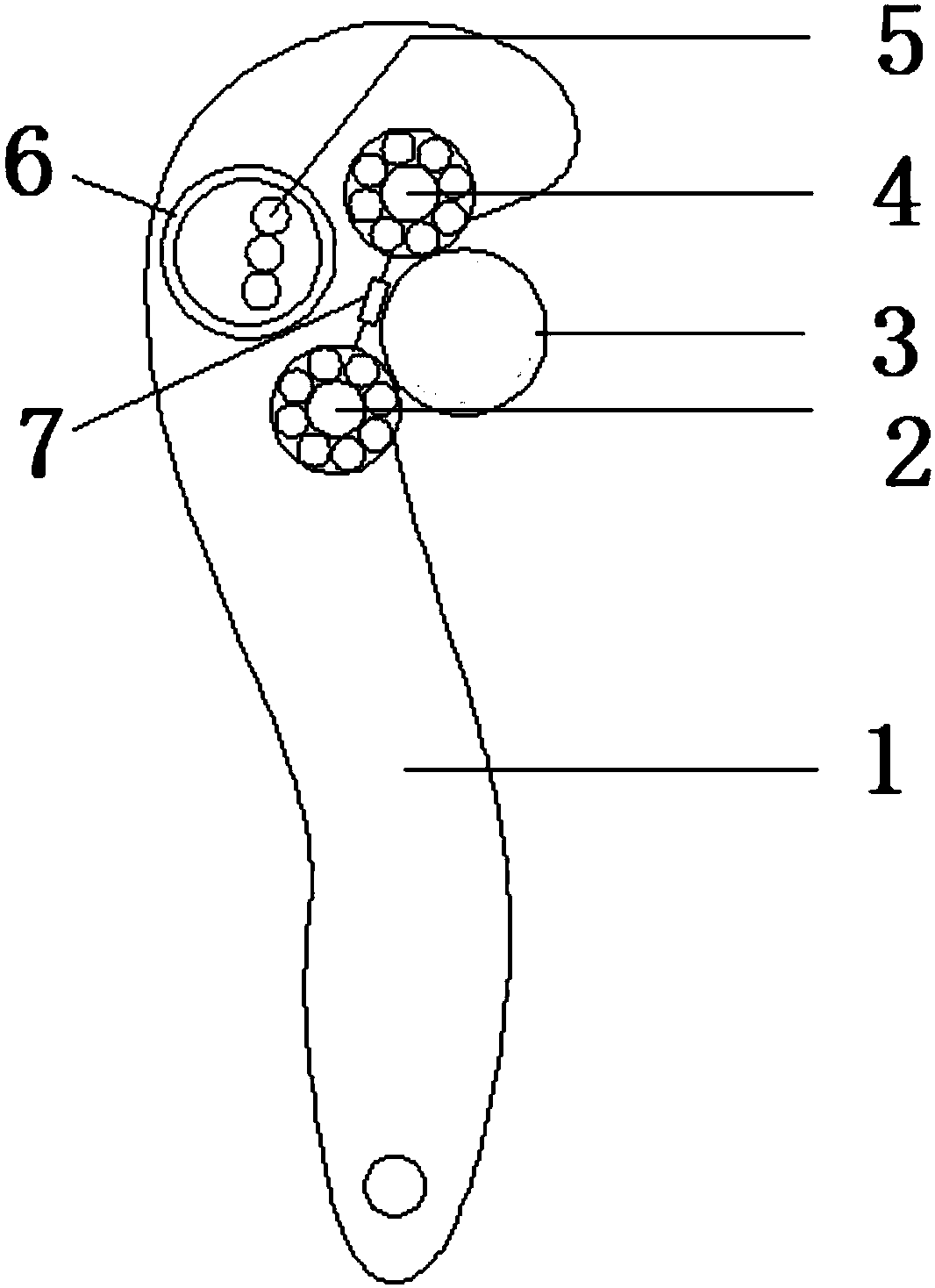

[0017] The invention provides a pre-twisted wire installation winder, characterized in that: the pre-twisted wire installation winder includes a wrench 1, a bearing three 2, a wire 3, a bearing two 4, a pre-twisted wire 5, and a bearing four 6 , bearing one 7;

[0018] Among them: the middle and upper part of the wrench 1 is a concave arc structure, bearing three 2, bearing two 4 and bearing one 7 are installed at the concave arc structure, bearing three 2, bearing two 4 and bearing one 7 are in rolling friction contact with the wire 3 Bearing 4 6 is installed in the back of the middle and upper part of wrench 1, and pre-twisted wire 5 is arranged in the bearing 4 6.

[0019] The said wrench 1 has a flat tail structure with a through hole.

[0020] The diameters of the first bearing 7 are smaller than the diameters of the third bearing 2 and the second bearing 4 .

[0021] The number of 5 pre-twisted wires is 2.

[0022] The tail of the wrench 1 is provided with a flexible ...

Embodiment 2

[0025] The invention provides a pre-twisted wire installation winder, characterized in that: the pre-twisted wire installation winder includes a wrench 1, a bearing three 2, a wire 3, a bearing two 4, a pre-twisted wire 5, and a bearing four 6 , bearing one 7;

[0026] Among them: the middle and upper part of the wrench 1 is a concave arc structure, bearing three 2, bearing two 4 and bearing one 7 are installed at the concave arc structure, bearing three 2, bearing two 4 and bearing one 7 are in rolling friction contact with the wire 3 Bearing 4 6 is installed in the back of the middle and upper part of wrench 1, and pre-twisted wire 5 is arranged in the bearing 4 6.

[0027] The said wrench 1 has a flat tail structure with a through hole.

[0028] The diameters of the first bearing 7 are smaller than the diameters of the third bearing 2 and the second bearing 4 .

[0029] Described bearing three 2 and bearing two 4 are deep groove ball bearings.

[0030] The number of 5 pr...

Embodiment 3

[0034] The invention provides a pre-twisted wire installation winder, characterized in that: the pre-twisted wire installation winder includes a wrench 1, a bearing three 2, a wire 3, a bearing two 4, a pre-twisted wire 5, and a bearing four 6 , bearing one 7;

[0035] Among them: the middle and upper part of the wrench 1 is a concave arc structure, bearing three 2, bearing two 4 and bearing one 7 are installed at the concave arc structure, bearing three 2, bearing two 4 and bearing one 7 are in rolling friction contact with the wire 3 Bearing 4 6 is installed in the back of the middle and upper part of wrench 1, and pre-twisted wire 5 is arranged in the bearing 4 6.

[0036] The said wrench 1 has a flat tail structure with a through hole.

[0037] The diameters of the first bearing 7 are smaller than the diameters of the third bearing 2 and the second bearing 4 .

[0038] Described bearing three 2 and bearing two 4 are deep groove ball bearings.

[0039] The number of 5 pr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com