A High Precision Syringe Using Piezoelectric Stack

A technology of piezoelectric stacking and injectors, which is applied in the field of injectors, can solve the problems that the control accuracy and output pressure of the injector flow output cannot be improved, the smoothness of the flow output and the response speed cannot be improved, and the structure of the injector is complex, etc., so as to improve the stroke and injection. The effect of high performance, simple structure and low production cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

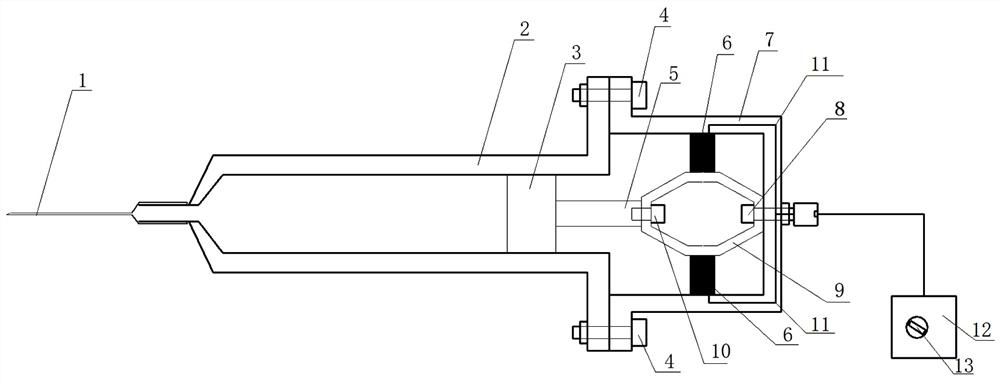

[0016] see figure 1 , the present invention adopts a piezoelectric stacked high-precision syringe, including an injection needle 1, a syringe outer cylinder 2, a piston 3 and a driving device, the piston 3 matches the inner diameter of the syringe outer cylinder 2, and the driving device communicates with the The pistons 3 are connected, and the driving device adopts two piezoelectric stack drivers 6 symmetrically arranged in the driving device fixing frame 7, and the driving device fixing frame 7 is connected and fixed with the syringe outer cylinder 2, and the output of the piezoelectric stack driver 6 The displacement is amplified by the triangular amplifying mechanism 9, and then the piston 3 is pushed through the connecting rod 5 for injection.

Embodiment 2

[0018] see figure 1 , the high-precision syringe using piezoelectric stacking in this embodiment differs from Embodiment 1 in that: the triangular amplifying mechanism is made of carbon, plastic, alloy or metal material with certain elasticity and toughness, which is symmetrical on both sides A diamond-shaped frame, one end of the tip of the diamond-shaped frame is fixed to the drive device fixing frame 7, and the other end is connected to the piston rod of the syringe. Two piezoelectric stack drivers 6 are symmetrically arranged on both sides of the diamond-shaped frame. A piezoelectric stack driver 6 is connected with a power supply and a switch. The triangular magnifying mechanism can be made of superhard aluminum alloy or brass material to form a bilaterally symmetrical rhombus frame structure.

[0019] As shown in the figure, the two piezoelectric stack drivers 6 are connected to the socket through the wire 11, and the socket is arranged at the tail end of the fixing fra...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com