Geotechnical centrifuge dynamic balance adjusting system

A geotechnical centrifuge and dynamic balancing technology, applied in centrifuges, measuring devices, instruments, etc., can solve problems such as limited trimming capability, complex system structure, and complex system composition, and achieve improved trimming capability, high system reliability, and simplification. The effect of system composition

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0042] The present invention will be further described below in conjunction with accompanying drawing:

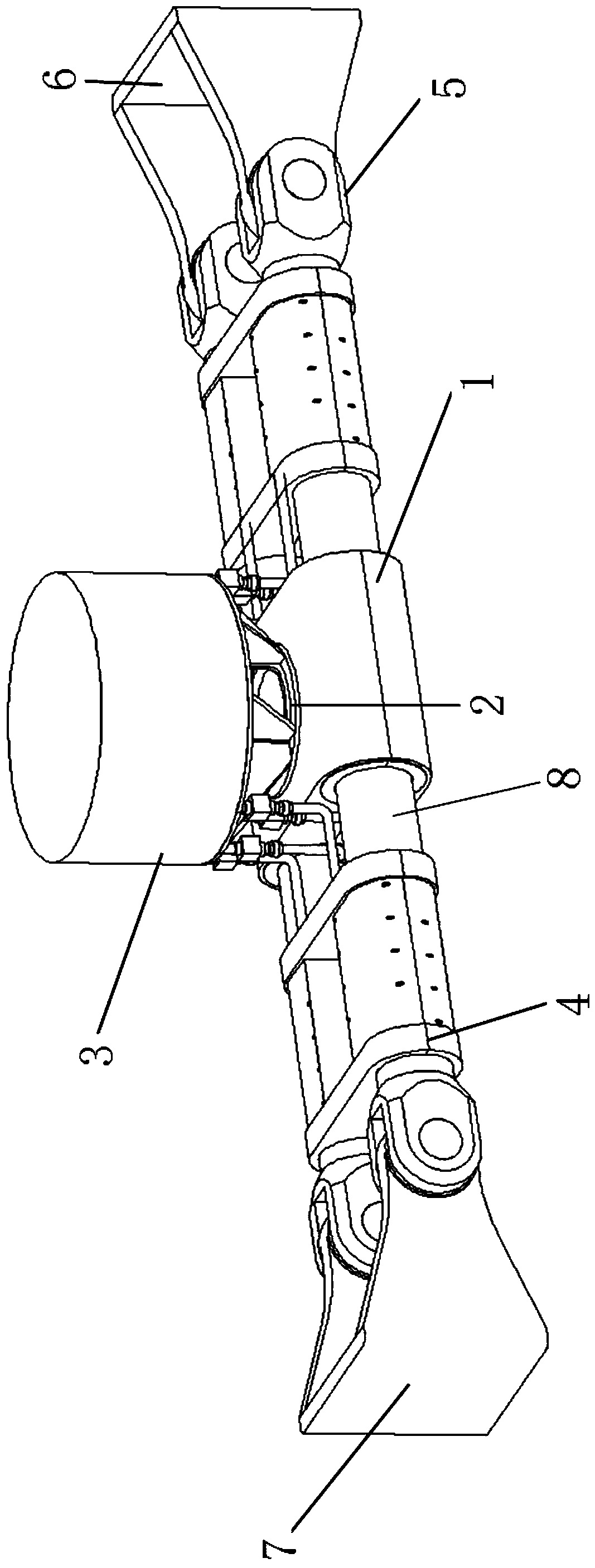

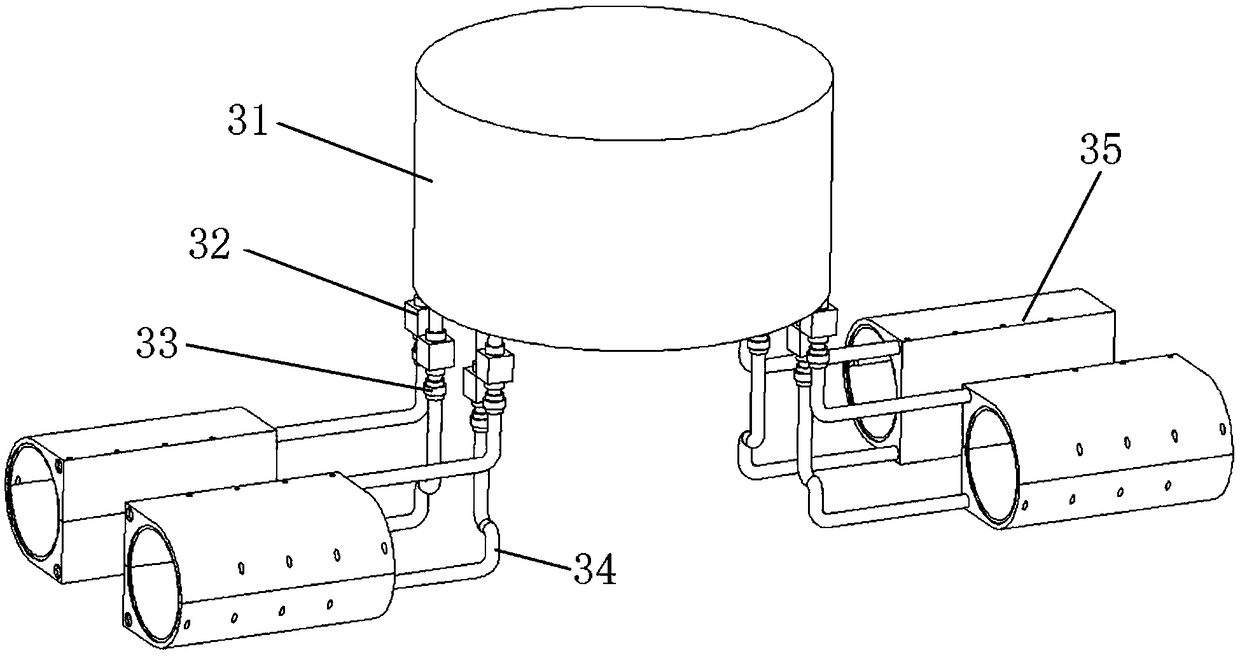

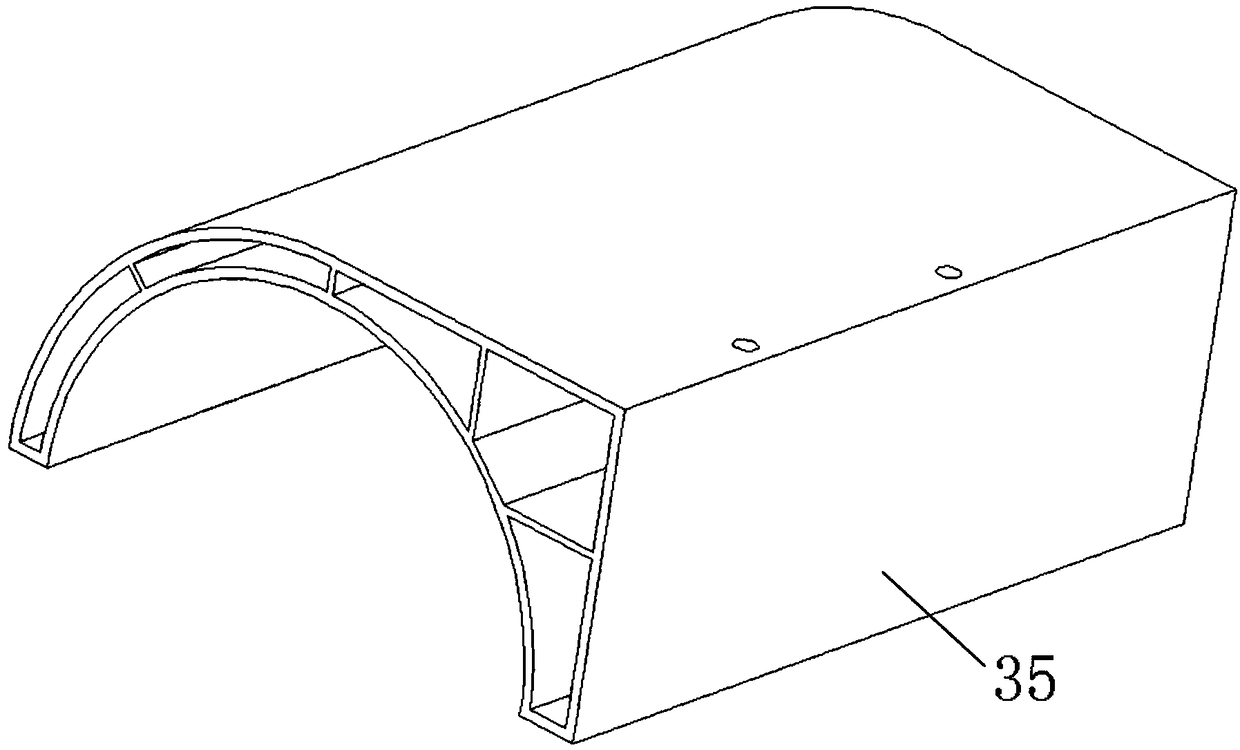

[0043] Such as Figure 1-Figure 2 As shown, the geotechnical centrifuge dynamic balance adjustment system 3 is installed on the geotechnical centrifuge and used for its dynamic balance adjustment. The dynamic balance adjustment system 3 includes: a high-level water tank 31 for water storage installed on the geotechnical centrifuge arm support 1 ; There are an even number of terminal water tanks 35 installed on the rotary arm 8 on both sides of the geotechnical centrifuge rotary arm support 1, and the terminal water tanks 35 located on both sides of the rotary arm support 1 are installed symmetrically with respect to the rotation center of the geotechnical centrifuge. The high-level water tank 31 The installation position is higher than the installation position of the end water tank 35; the plurality of pipelines 34 installed on the geocentrifuge for connecting the high wat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com