Dust removing device dedicated to computer numerical control cutter

A technology of a dust removal device and a cutting machine, which is applied in the directions of removing smoke and dust, cleaning methods and appliances, gas flame welding equipment, etc. Problems, reasonable design of device structure, high efficiency of smoke and dust capture

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

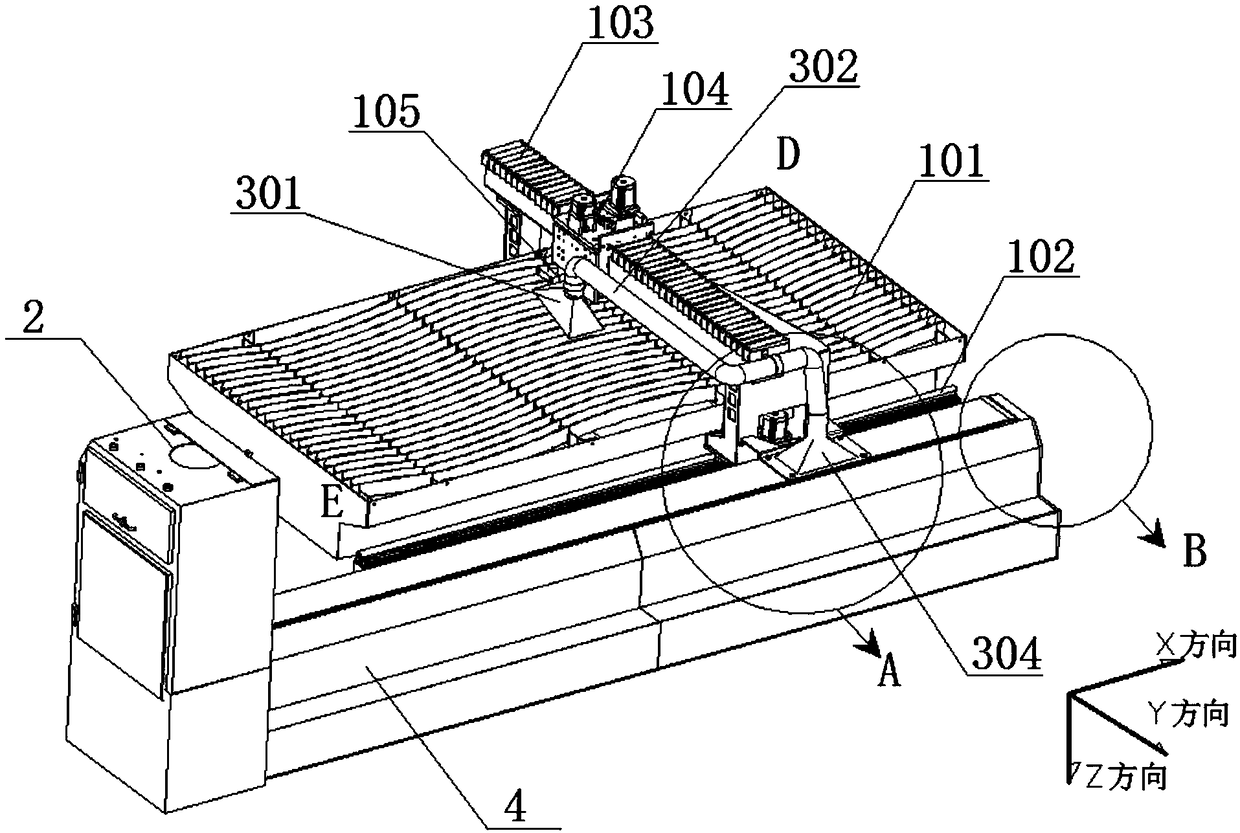

[0022] Such as figure 1 As shown, a special dust removal device for CNC cutting machine involved in this embodiment includes a dust collection device 3, a gas channel 4 and a dust collector 2, and the collection port of the dust collection device 3 fixed on the trolley 104 is always aligned with the cutting torch 105 for collection. Smoke, dust collection device 3 can drive the collection port of the dust collection device to move in the Y direction.

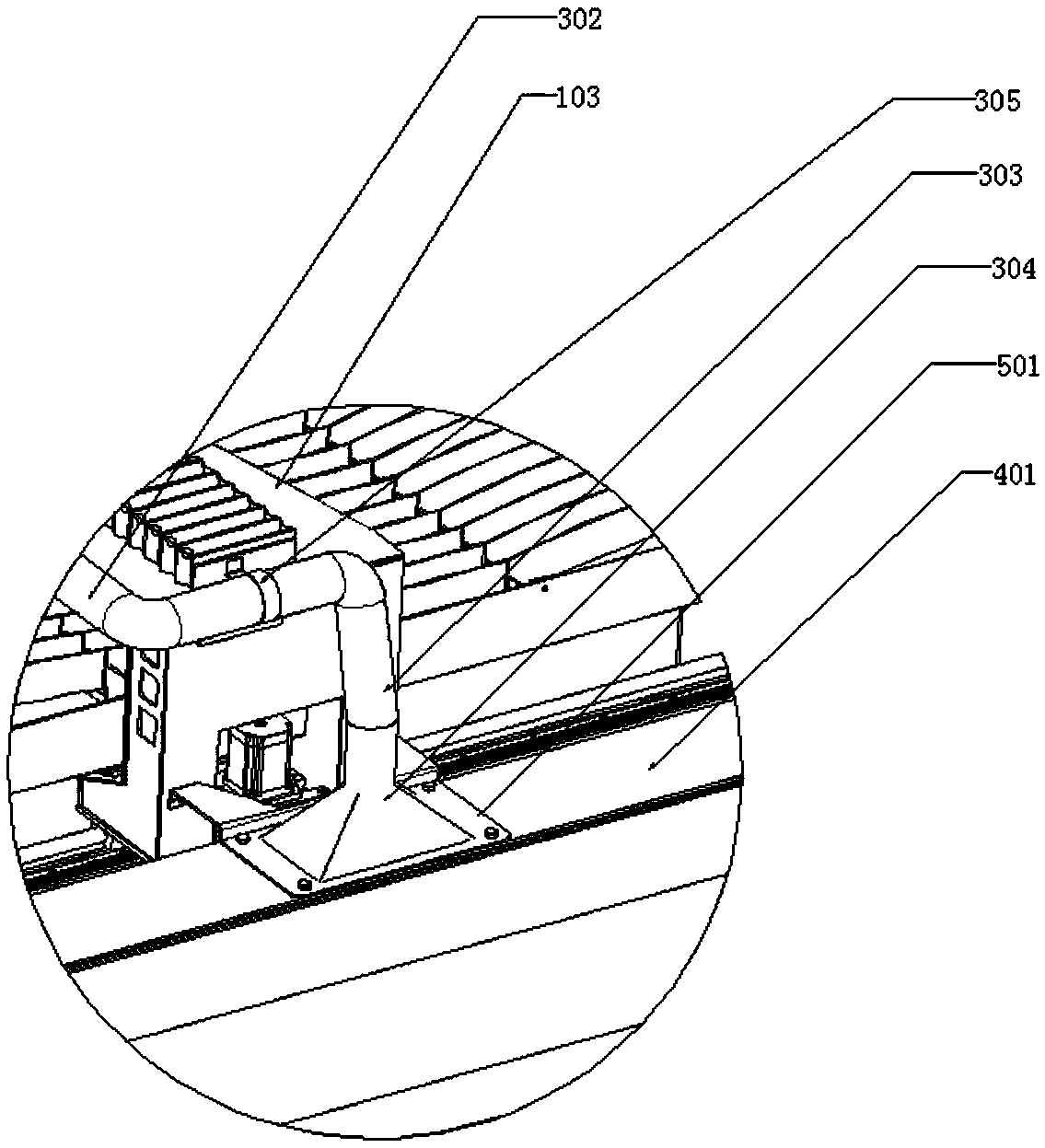

[0023] Further, as Figure 1-2 As shown, the dust collection device 3 includes a first dust collection hood 301, a bellows 302, an L-shaped elbow 303 and a second dust collection hood 304, the first dust collection hood 301 is fixed on the trolley 104 and the first dust collection The collection port of the cover 301 is aligned with the cutting torch 105 to collect smoke and dust. The first integrated cover 301 is connected to one end of the bellows 302 arranged in the Y direction along the gantry 103, and the other end of the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com