Oil field signal cable repairing machine

A signal cable and repair machine technology, applied in the direction of insulation/armored cable repair equipment, etc., can solve the problems of low efficiency, time-consuming, high cost, etc., and achieve the effect of simple structure, high-efficiency signal line repair equipment, and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

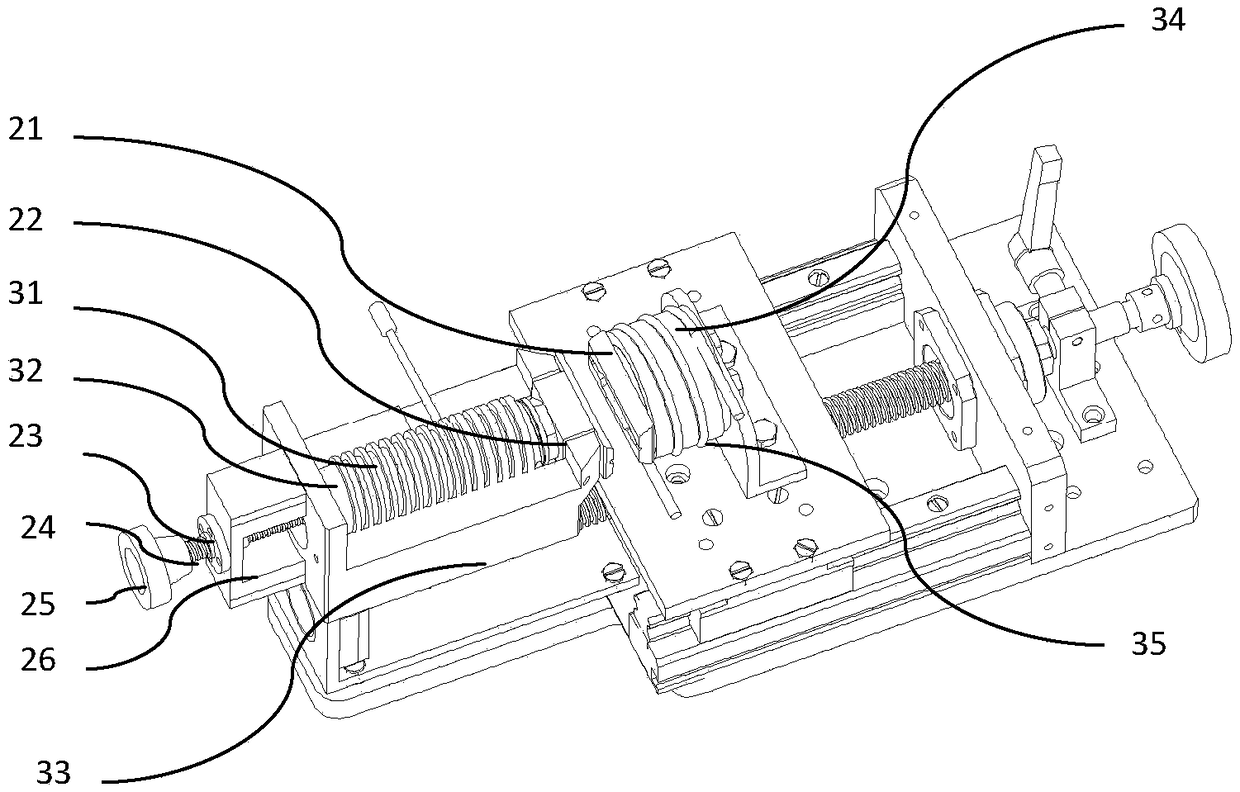

[0036] The present invention will be further described below in conjunction with the accompanying drawings: these accompanying drawings are all simplified schematic diagrams and only illustrate the basic structure of the present invention in a schematic manner, so it only shows the composition related to the present invention.

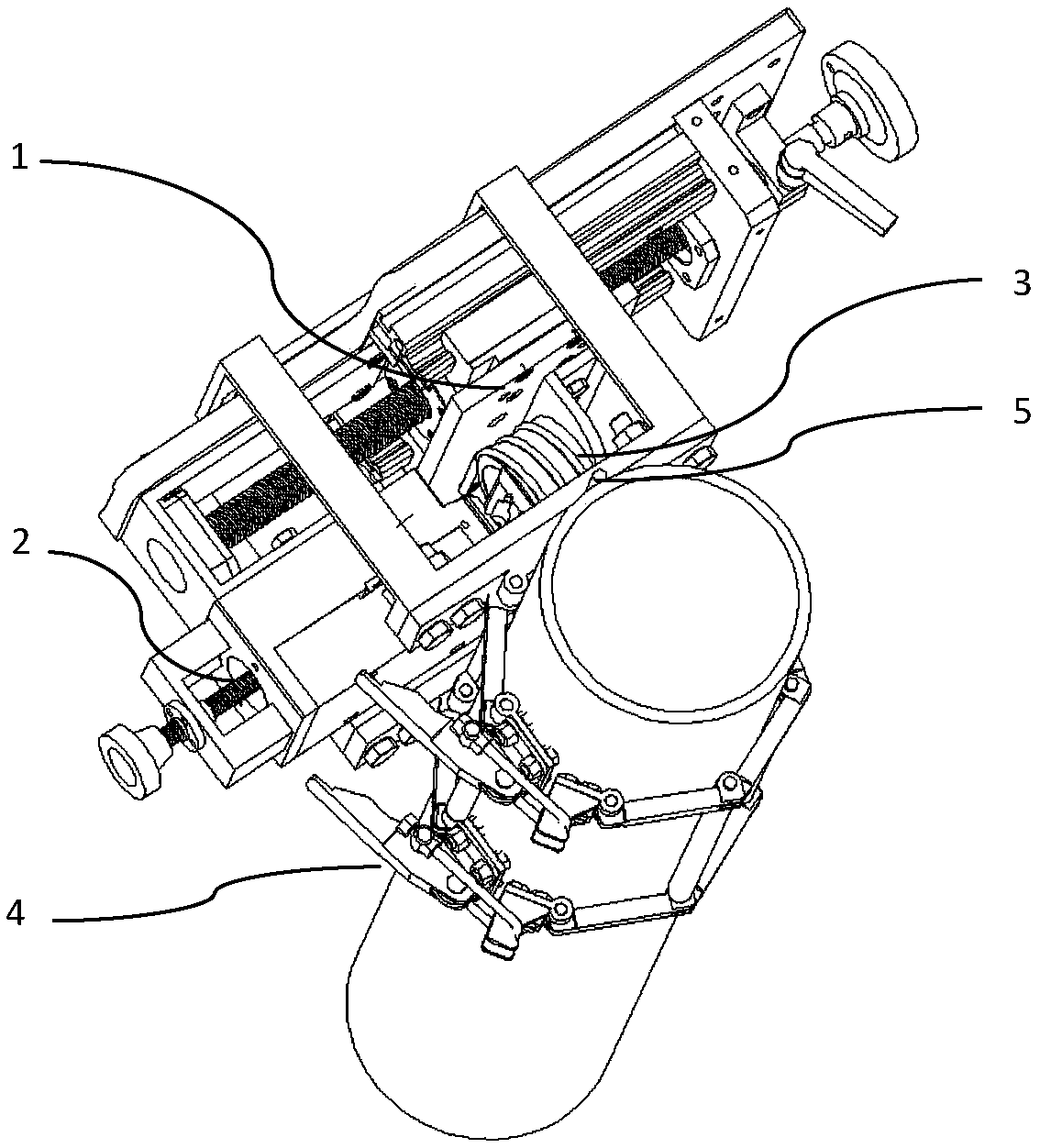

[0037] Such as figure 1 As shown, the oilfield signal cable repairing machine of this example is composed of a mobile device 1, an extrusion molding device 2, a heating device 3, a fixing device 4, and a cable 5.

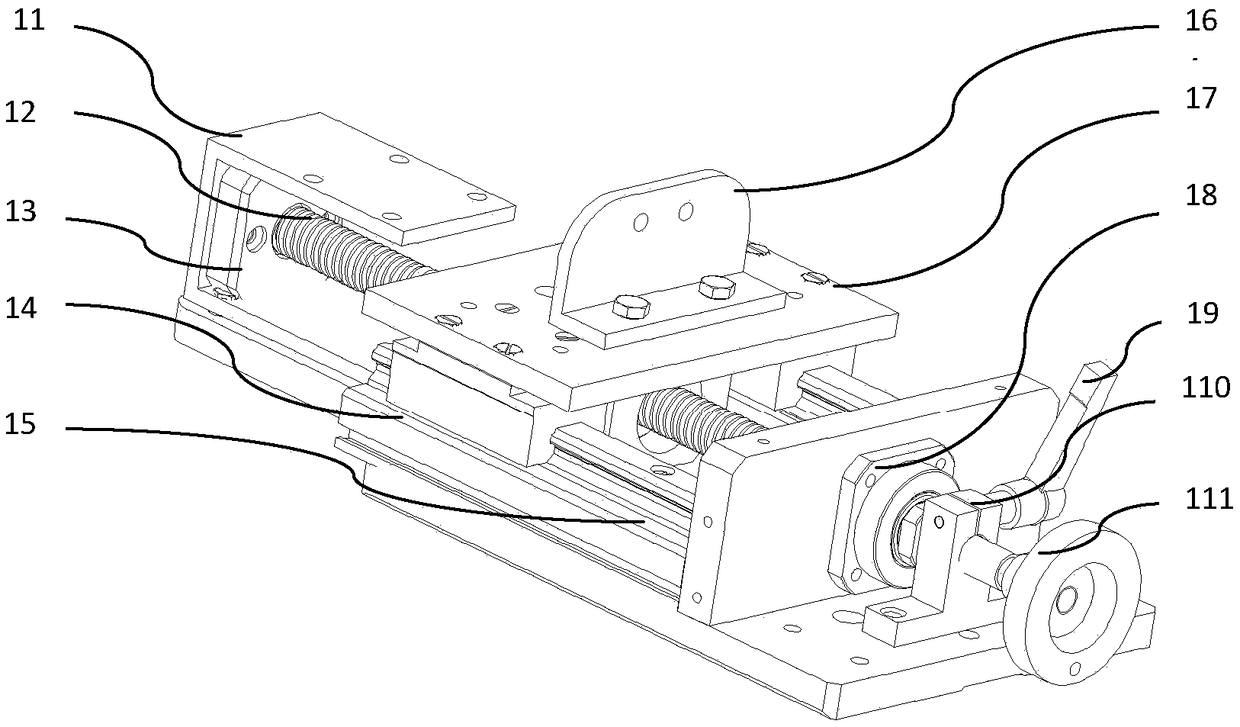

[0038] Such as figure 1 As shown, the mobile device 1 includes: a slide rail 15, a slider 14, a slide table 112, a slide plate 17, a lead screw 12, a lead screw buckle 110, a first hand wheel 111, a fixed lock 19, and a connecting frame 11, etc. .

[0039] Such as figure 2As shown, the mobile device 1 is fixed on the bottom plate 42 in the fixing device 4, and is fixed with the fixing device 4 through bolt connection. The middle part of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com