Positioning device before clamped fixing of pen holder and pen point

A positioning device and pen tip technology, which is applied in the direction of transportation and packaging, conveyors, conveyor objects, etc., can solve the problems of difficult to guarantee the reliability of clamping, uncontrollable position and degree of clamping, and low efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

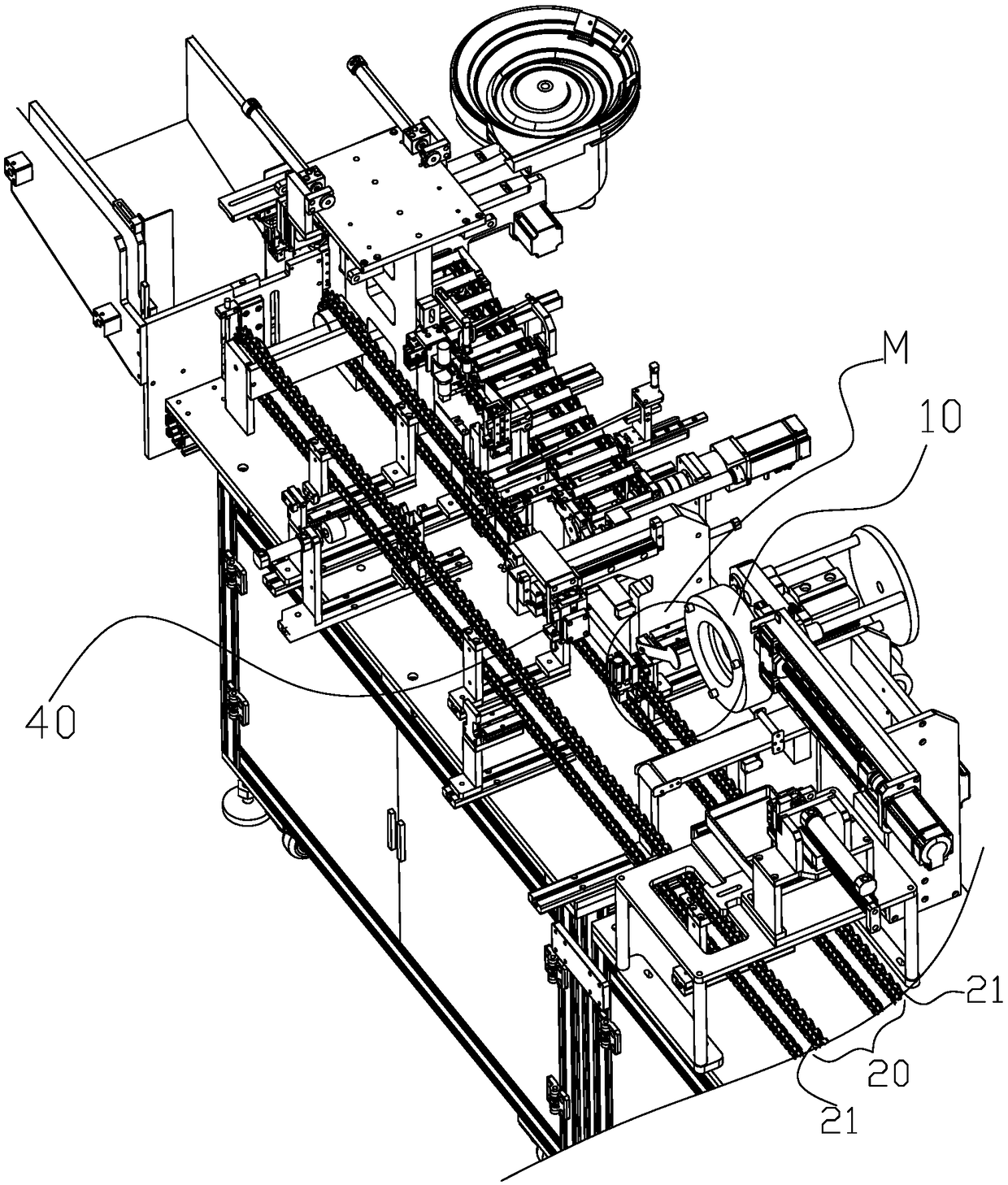

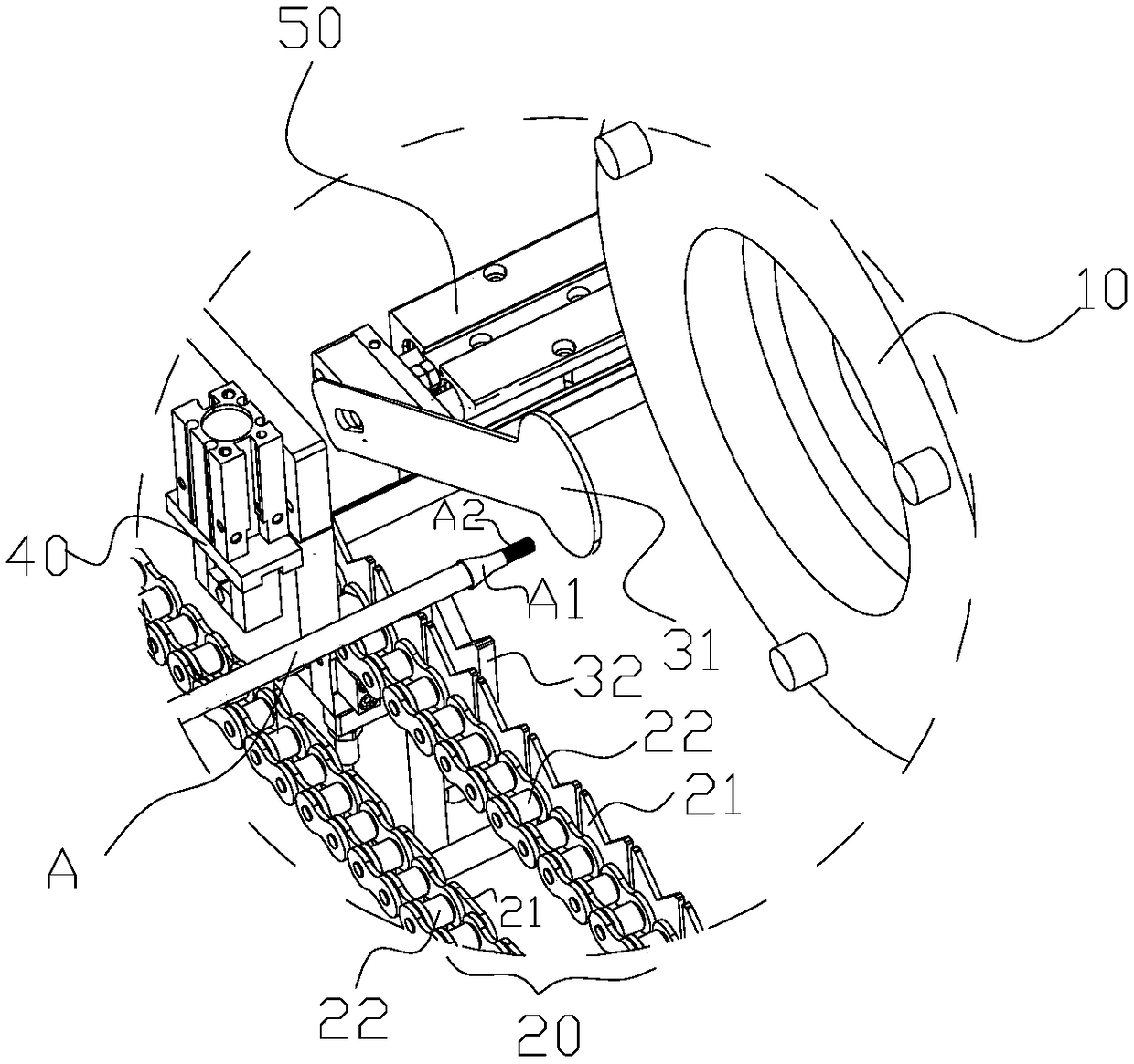

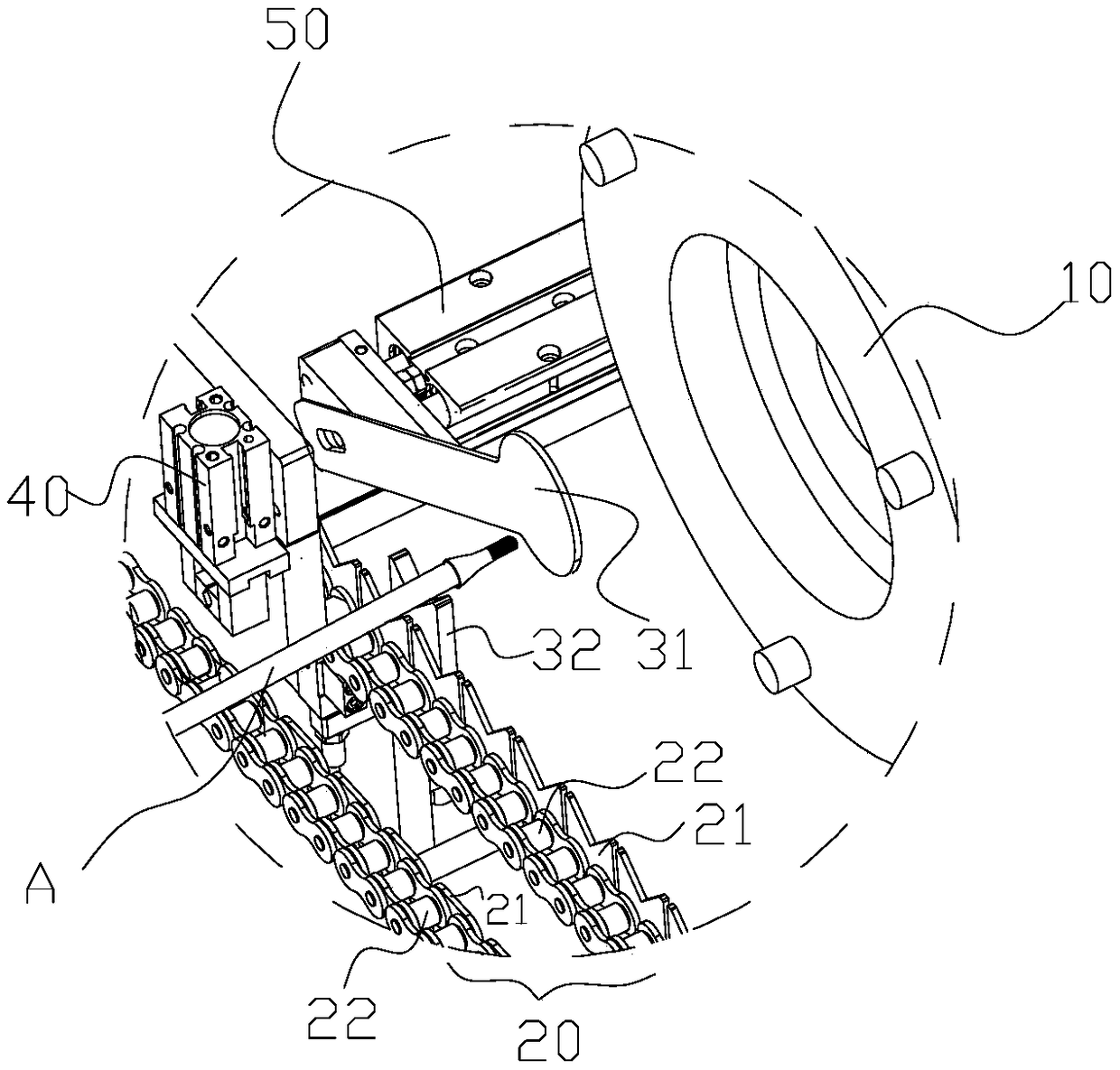

[0008] In conjunction with the accompanying drawings, the positioning device before the nib of the pen holder is clamped includes the initial loading pen conveying mechanism 20, the conveying direction of the initial loading pen conveying mechanism 20 is perpendicular to the length direction of the initial loading pen, and the initial loading pen is set on the transmission path of the initial loading pen Positioning mechanism, the initial loading pen positioning mechanism is located at the side of the initial loading pen delivery mechanism 20, and the initial loading pen positioning mechanism is used to limit the position of the nozzle of the nib tube A1 in the vertical direction of the initial loading pen delivery mechanism 20 delivery direction.

[0009] After the nib containing the brush hair A2 and the nib tube A1 is inserted into the pen barrel A to make the primary pen, the position of the primary pen in the direction of its length cannot be determined during the process o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com