Device for saving resources and reducing discharge waste

A resource-saving and discharge hole technology, applied in thin material handling, transportation and packaging, sending objects, etc., can solve the problems of time-consuming, laborious, material waste, etc., and achieve the effect of convenient use and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The present invention and specific implementation thereof are described in further detail below in conjunction with accompanying drawing:

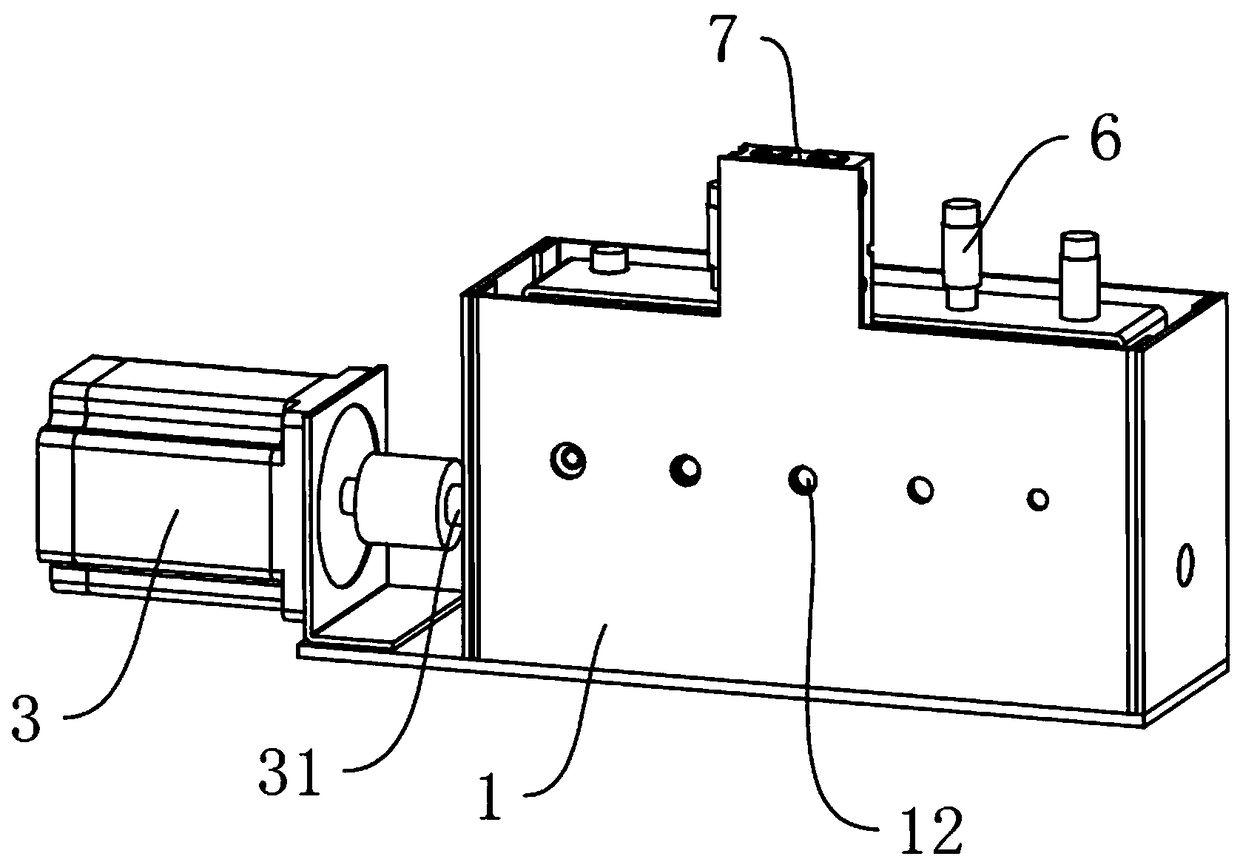

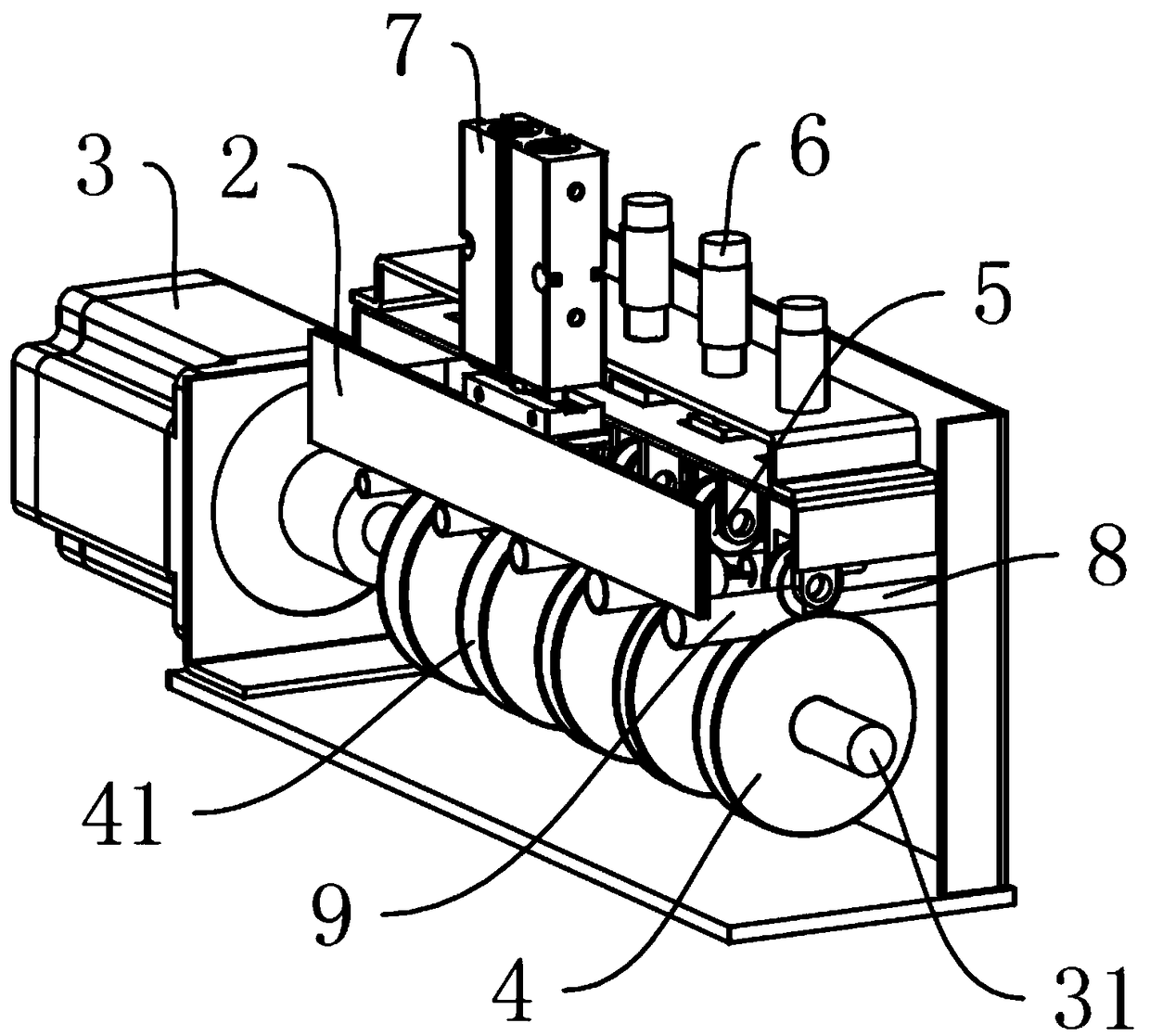

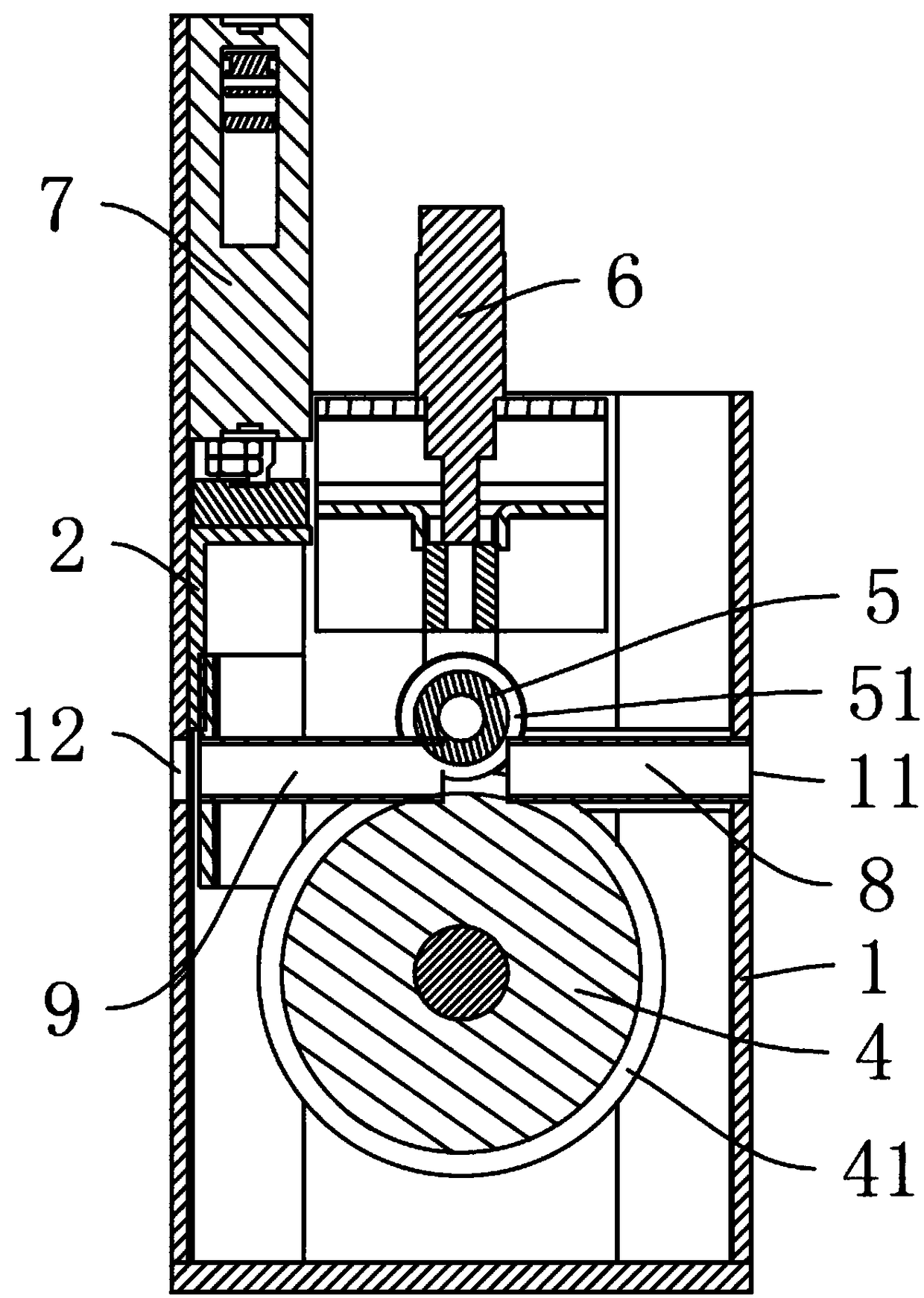

[0018] see Figure 1 to Figure 3 , the present invention comprises shell 1, cutter 2, is characterized in that: also comprises stepper motor 3, roller 4, roller 5, and roller 4 is fixed on the rotating shaft 31 driven by stepper motor 3, and roller 5 is driven by the first The pushing device 6 pushes towards the direction of the roller 4, and the shell 1 is provided with a feed hole 11 and a discharge hole 12, the discharge hole 12 corresponds to the gap between the roller 4 and the roller 5, and the cutter 2 is located in the discharge hole 12 and the gap, the cutter 2 is pushed by the second pushing device 7 to cut off the material output from the discharge hole 12 . Put the material to be cut into the product from the feeding hole 11 and extend into the gap between the roller 4 and the roller 5, the first pushing device 6 pushes...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com