Bridge swivel construction intelligent control system

A construction intelligence and control system technology, applied in general control systems, control/regulation systems, bridges, etc., can solve the problems of wasting resources, consuming manpower and material resources, and stopping hoisting, achieving intelligent detection and construction, reducing manpower and material resources, Avoid the effect of lateral movement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0052] The specific implementation manner and working principle of the present invention will be further described in detail below in conjunction with the accompanying drawings.

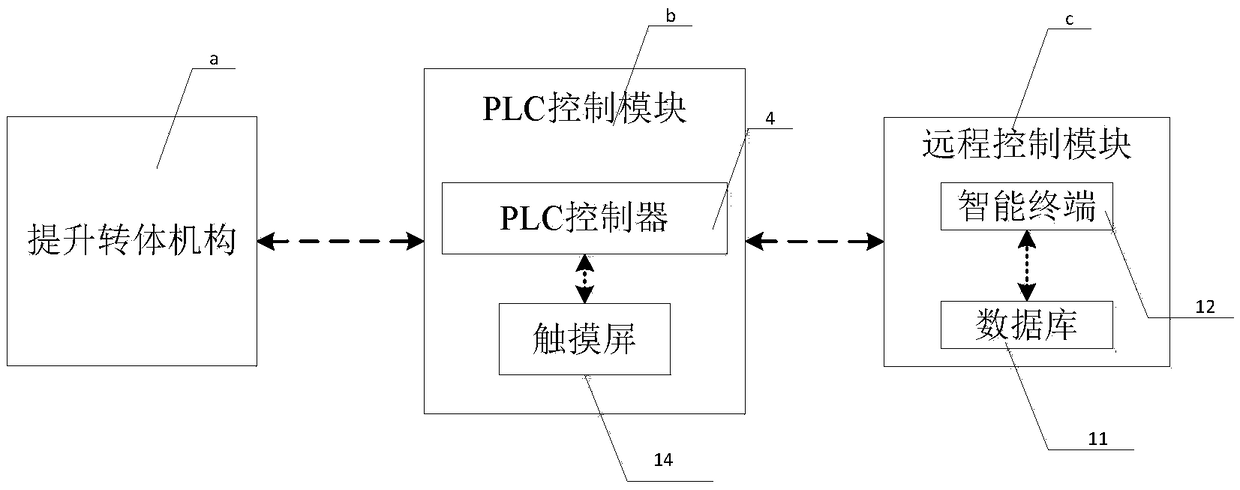

[0053] from figure 1 It can be seen that an intelligent control system for bridge swivel construction includes a lifting swivel mechanism a, a PLC control module b and a remote control module c;

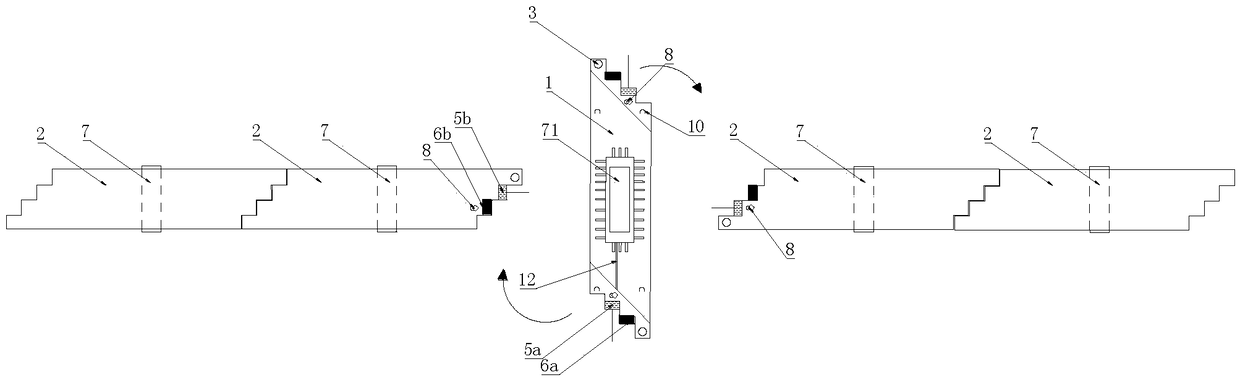

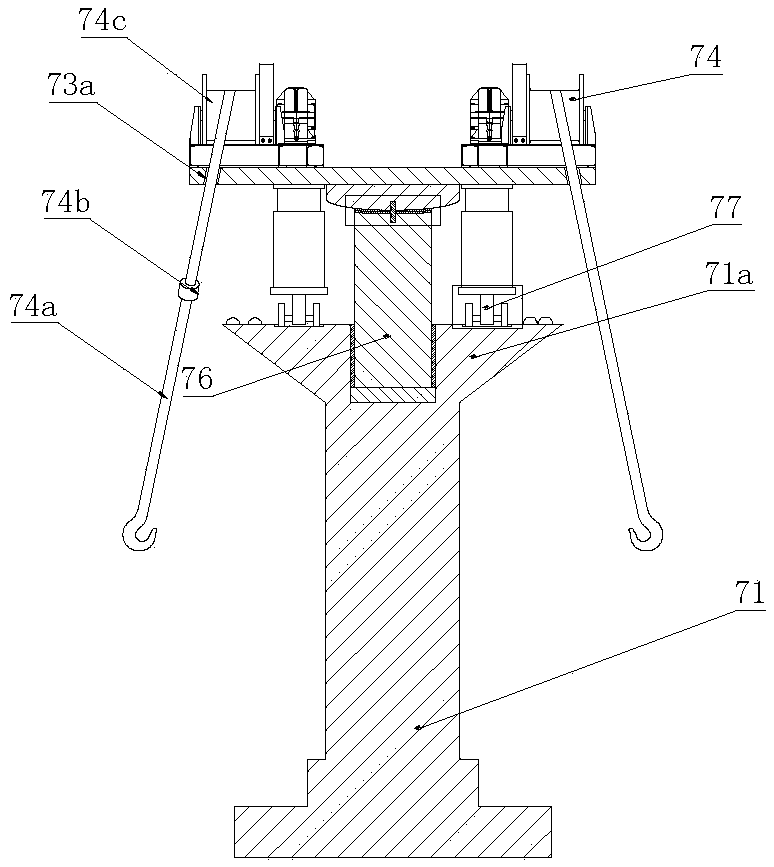

[0054] The lifting swivel mechanism a is provided with a pier column 71 and a beam pouring platform 72, and the beam pouring platform 72 is used for pouring the rotating beam body 1; the pier column 71 is used for lifting the rotating beam body 1 and support in the swivel; the PLC control module b is provided with a PLC controller 4 and a touch screen 14, the PLC controller 4 is connected with the touch screen 14, and a data setting module and a display module are arranged on the touch screen 14 , an automatic module and a manual module; the PLC controller 4 is used to control the lifting and swivel proces...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com