Prestressing-force concrete tower structure and construction method thereof

A construction method and concrete technology, which is applied to towers, building types, buildings, etc., can solve problems such as high cost and long construction period, and achieve the effects of reducing production costs, speeding up construction assembly speed, and improving hoisting construction efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

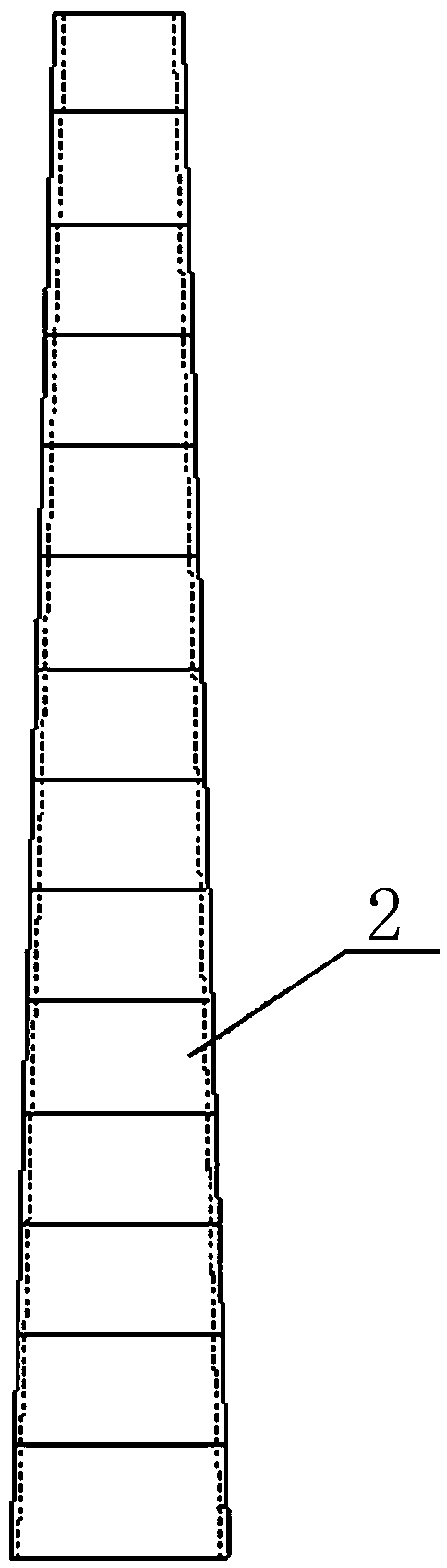

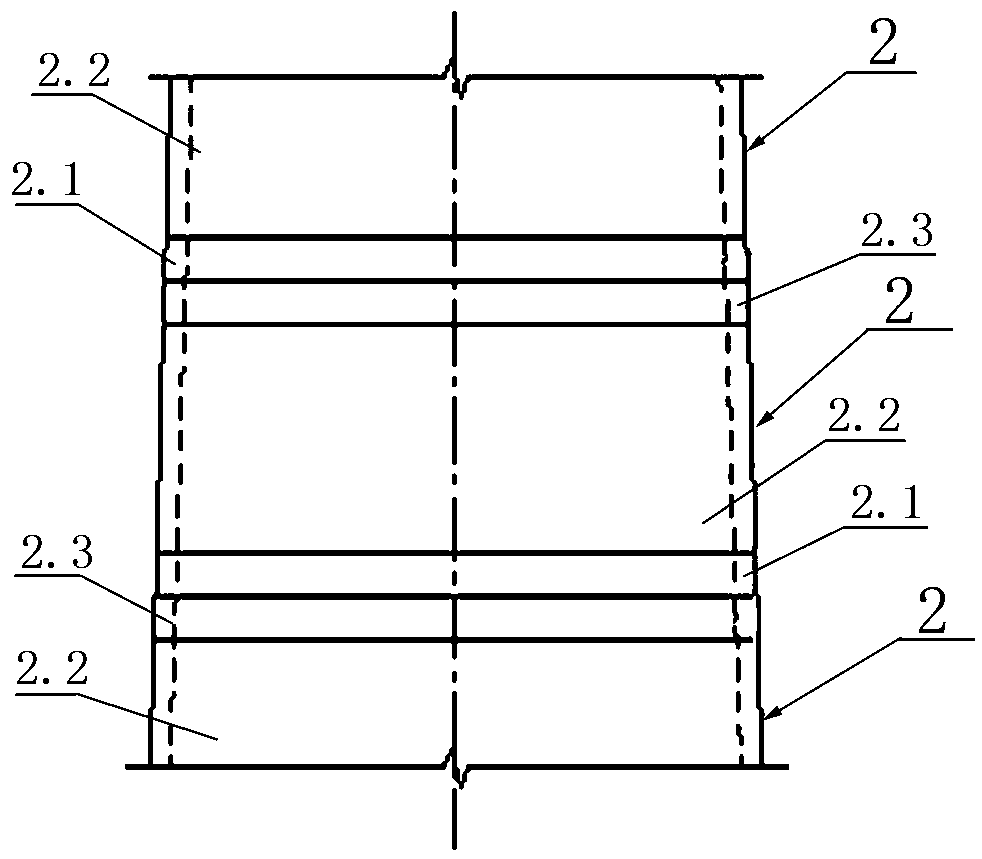

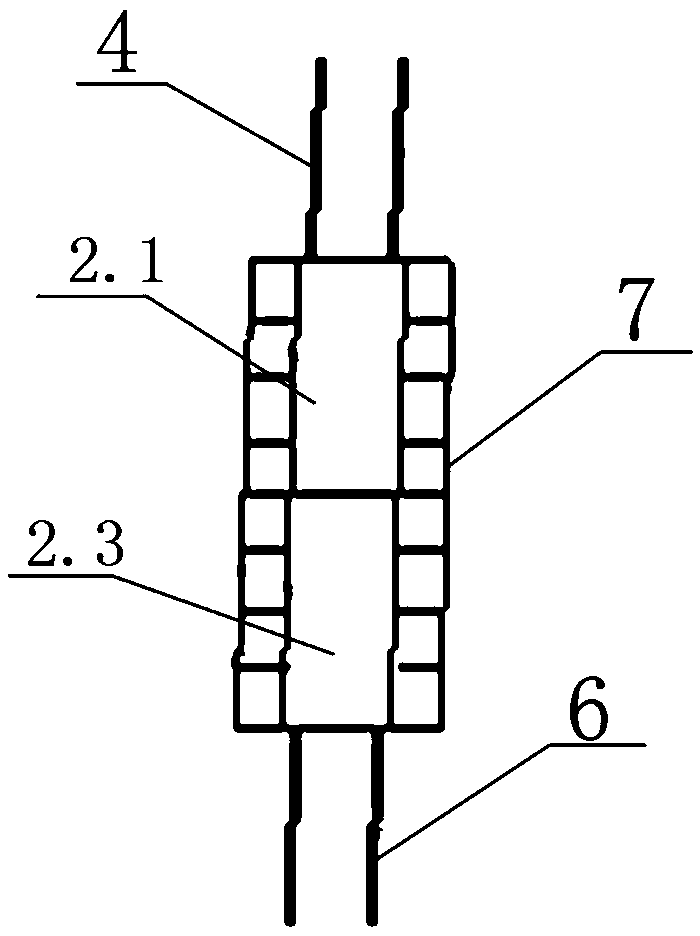

[0045] As shown in the figure, this prestressed concrete tower structure includes a tower segment 2; the tower segment 2 has a group and is connected in sequence along the vertical; wherein the horizontal section of each tower segment 2 is It is in the shape of a ring; the column segment 2 includes a lower connecting ring segment 2.1, an intermediate ring segment 2.2 and an upper connecting ring segment 2.3 from bottom to top; the inner side of the lower connecting ring segment 2.1 is close to the bottom There is a lower embedded part 3, and the top connecting steel bar 4 is reserved on the top surface of the lower connecting ring section 2.1, and the upper end of the top connecting steel bar 4 exceeds the top surface of the lower connecting ring section 2.1; the upper connecting ring section 2.3 On the inner side of the top surface, near the top surface, there is an upper embedded part 5, and a bottom connecting steel bar 6 is reserved on the bottom surface of the upper connec...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com