Display module and terminal

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

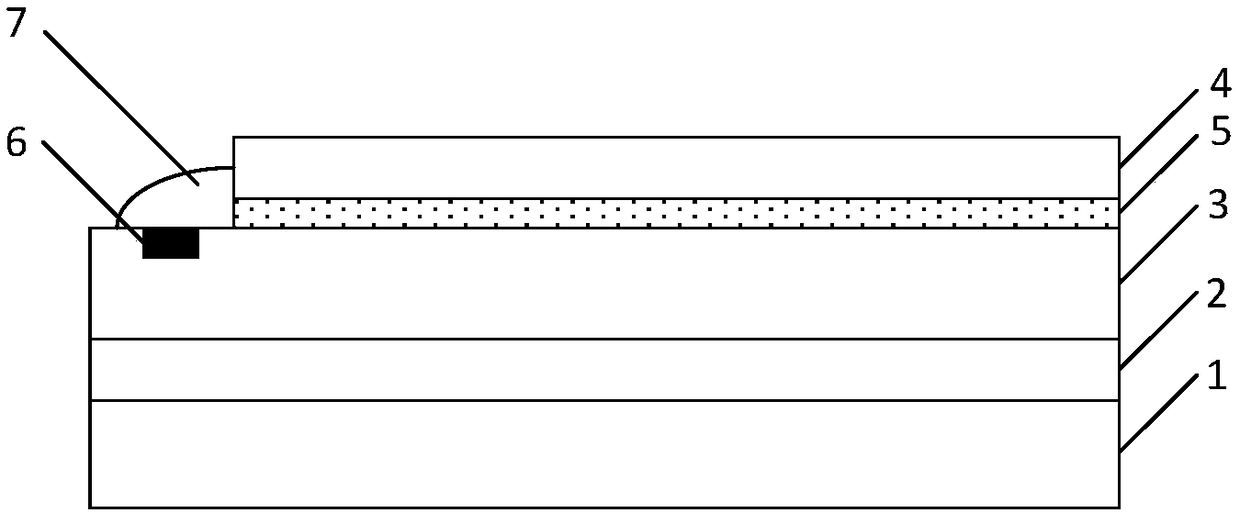

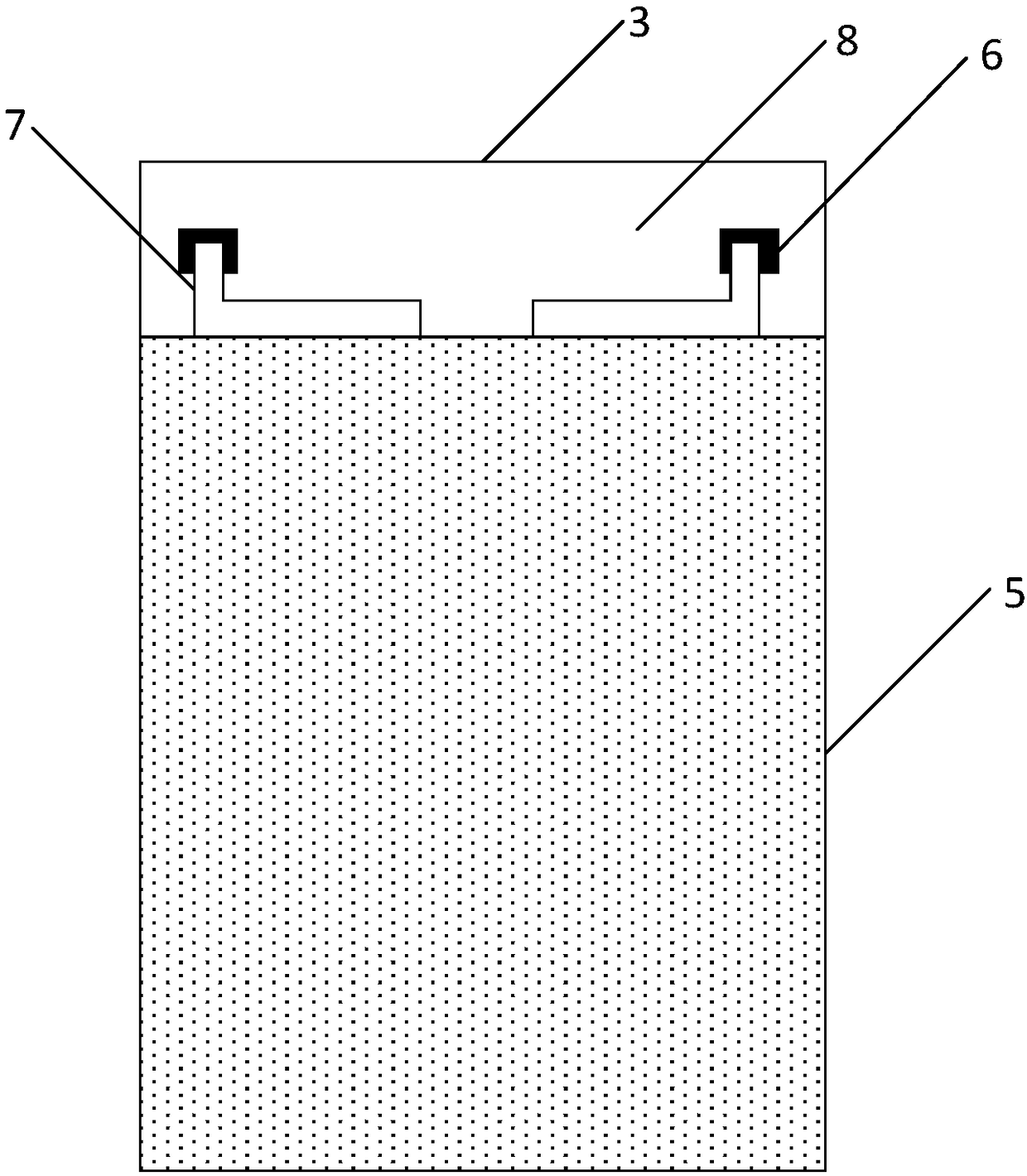

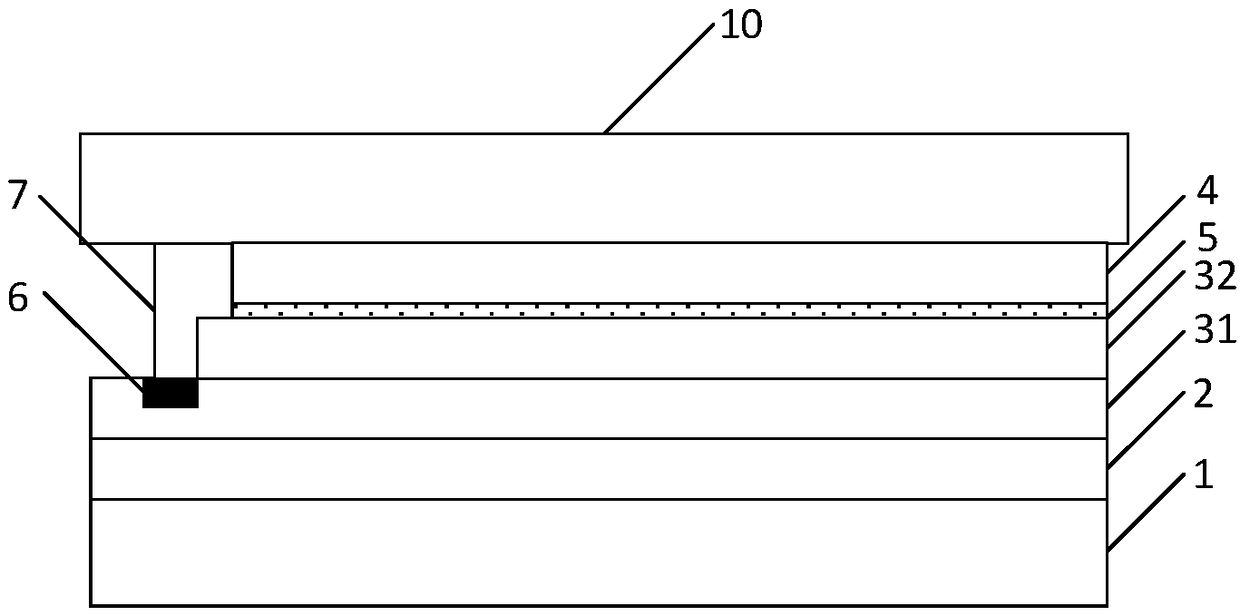

[0030] The core of the invention is to provide a display module. In the prior art, a layer of high-resistance film is usually provided on the upper surface of the liquid crystal cell, and the high-resistance film is used to prevent static electricity from causing poor display and other effects on the liquid crystal cell. At the same time, the high-resistance film and the grounding ground are electrically connected to each other through the conductive silver paste, so that the static electricity accumulated on the high-resistance film is released through the grounding ground. However, in the prior art, the process of coating a high-resistance film on the surface of the liquid crystal cell is complicated, and the cost of the high-resistance film is relatively high, which will greatly increase the manufacturing cost of the display module.

[0031] In the display module provided by the present invention, the upper polarizer is pasted on the surface of the liquid crystal cell facin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com