Diaphragm pump

A technology of diaphragm pumps and diaphragms, which is applied in the direction of pumps, pump components, variable displacement pump components, etc., can solve problems such as difficult control of valve discs, and achieve the effect of simple structure and high sealing performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

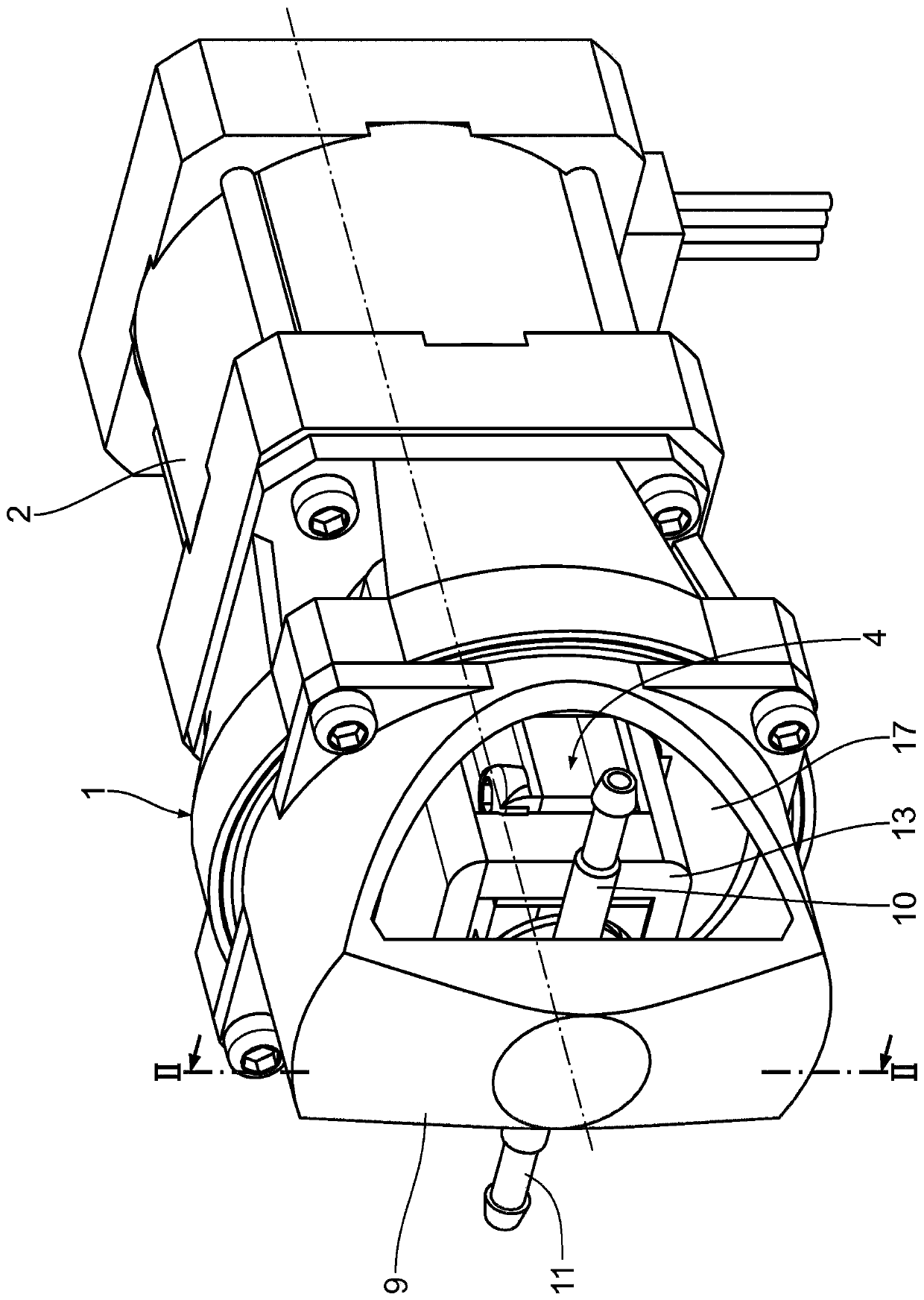

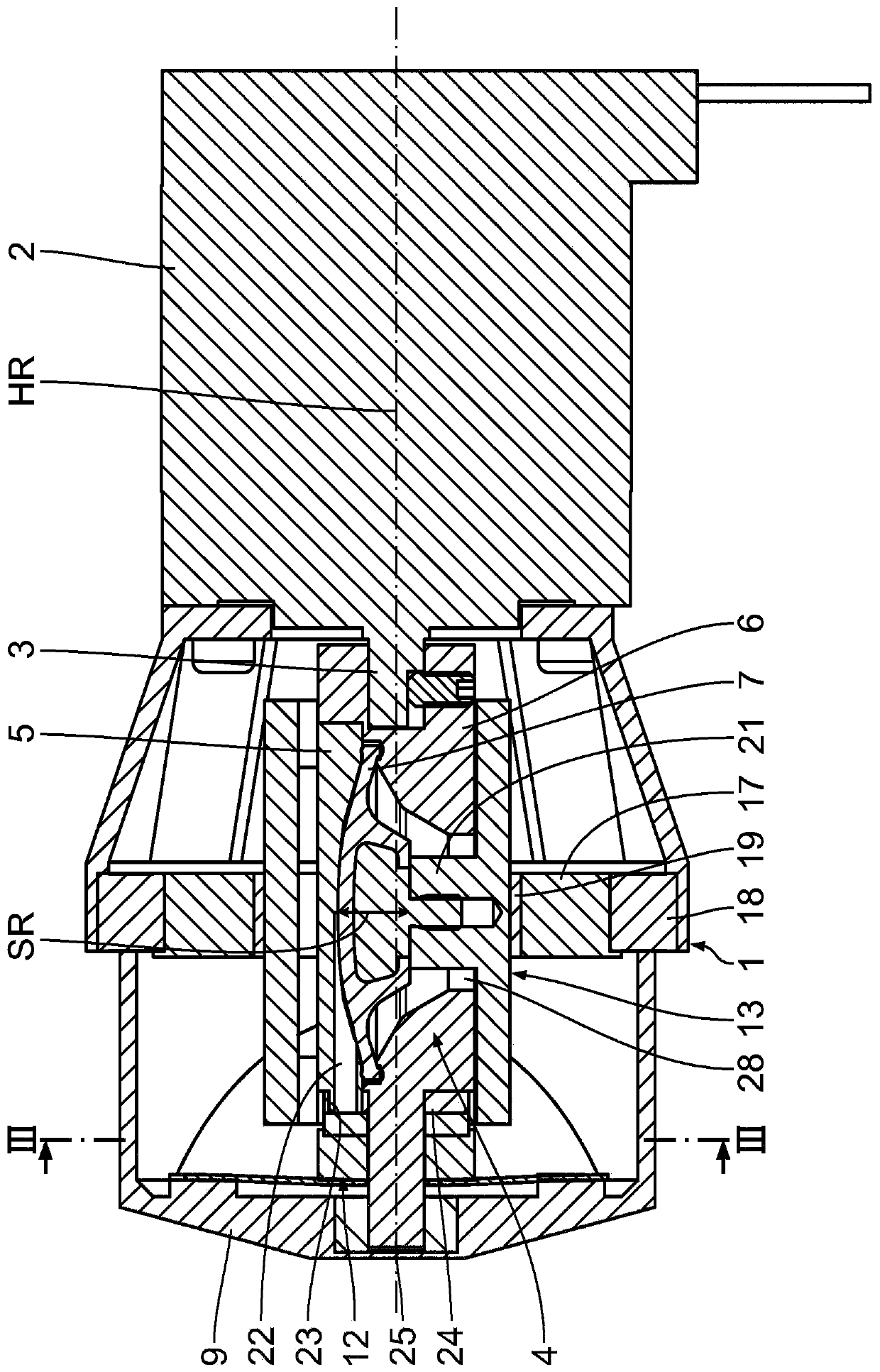

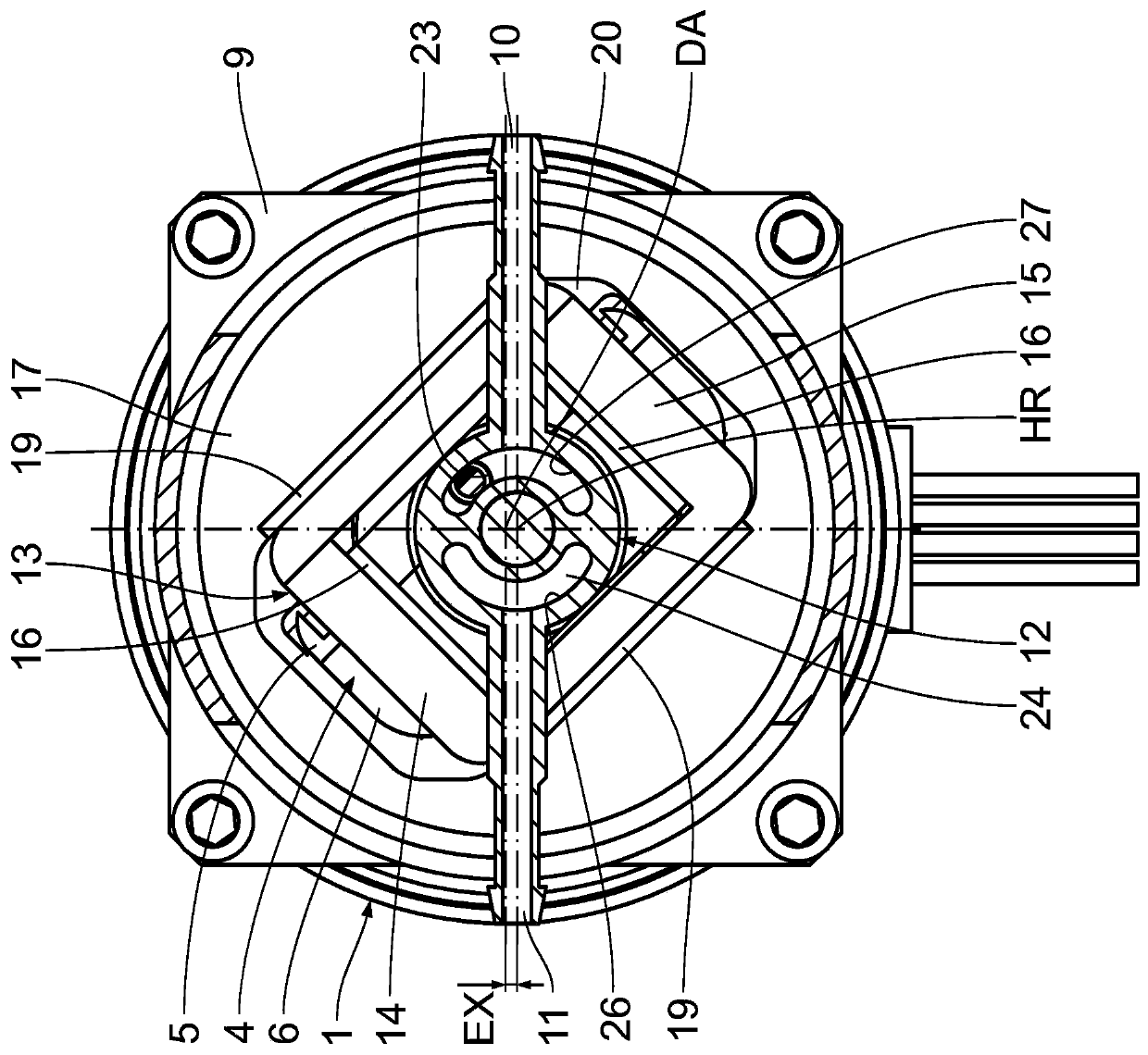

[0051] as from figure 1 and 2 It becomes clear that the illustrated diaphragm pump has a frame-shaped carrier part 1 functioning as a pump housing, on which an electric drive motor 2 is accommodated. exist Figure 4 The drive motor 2 , shown only schematically below, has a drive shaft 3 , which rotates about a main axis of rotation HR. The pump head, generally designated 4, is composed of an upper part 5 and a lower part 6, which delimit a conventional lens-shaped working volume. In this working space, a diaphragm 7 is clamped between the upper part 5 and the lower part 6 , which together with the upper part 5 delimits a pump chamber 8 . The pump head 4 is rotatably mounted in the carrier part 1 in a manner still to be explained in detail and is connected here with the drive shaft 3 in such an orientation that the vibration direction SR of the diaphragm 7 is orthogonal to the main axis of rotation HR of the drive shaft 3 ground pointing.

[0052] as from figure 1 and 3 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com