Tool-setting adjusting assembly for cutting moving cutter and hay cutter with assembly

A technology of assembly and guillotine cutting, applied in agricultural machinery and tools, cutting equipment, applications, etc., can solve the high time cost and labor cost of knife adjustment, difficulty in mastering the operation skills of knife adjustment and knife setting, and affect the utilization rate of hay cutter and other problems, to achieve the effect of easy control of the knife setting gap, improve the efficiency and quality of hay cutting operation, and reduce the labor load

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

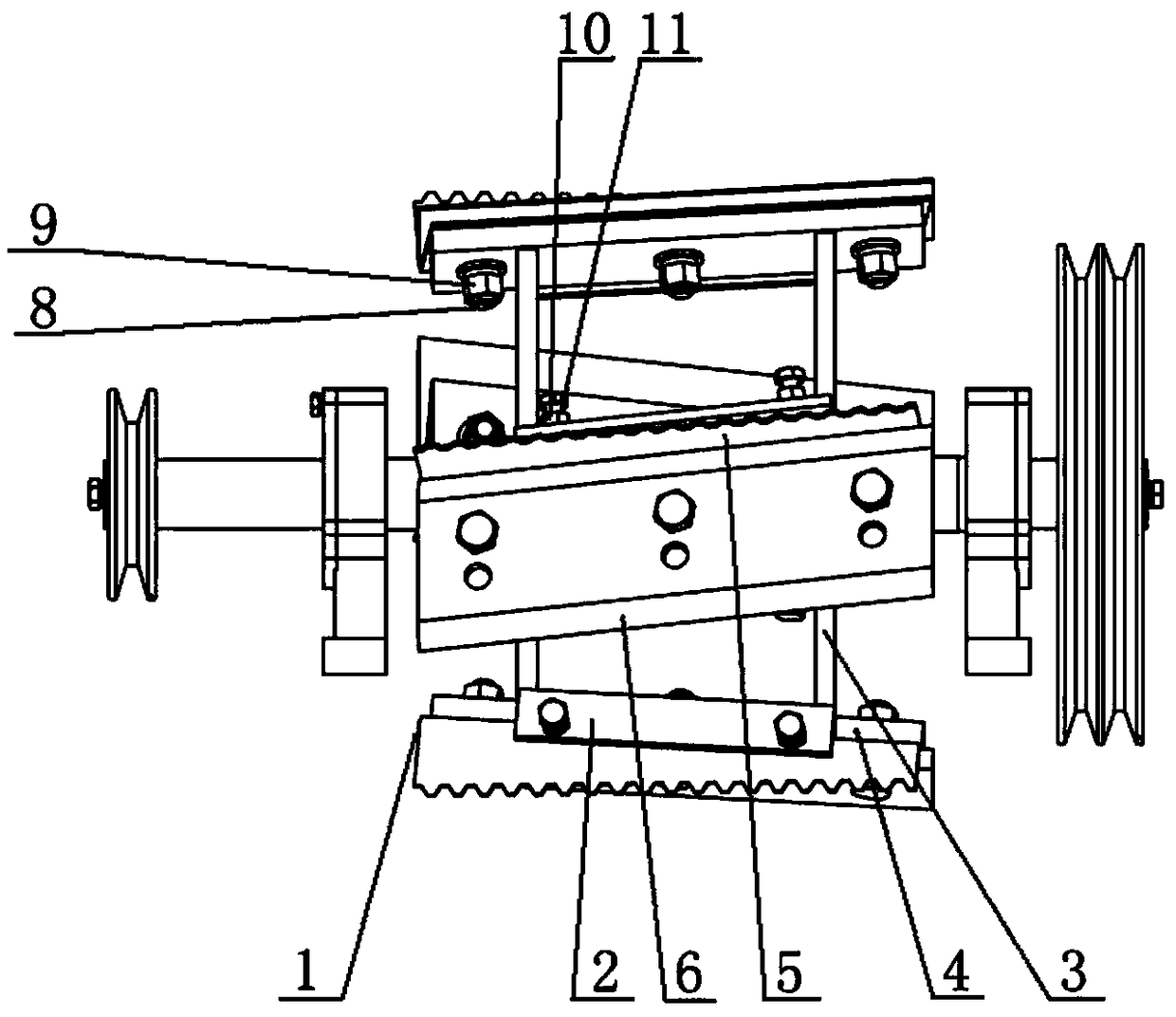

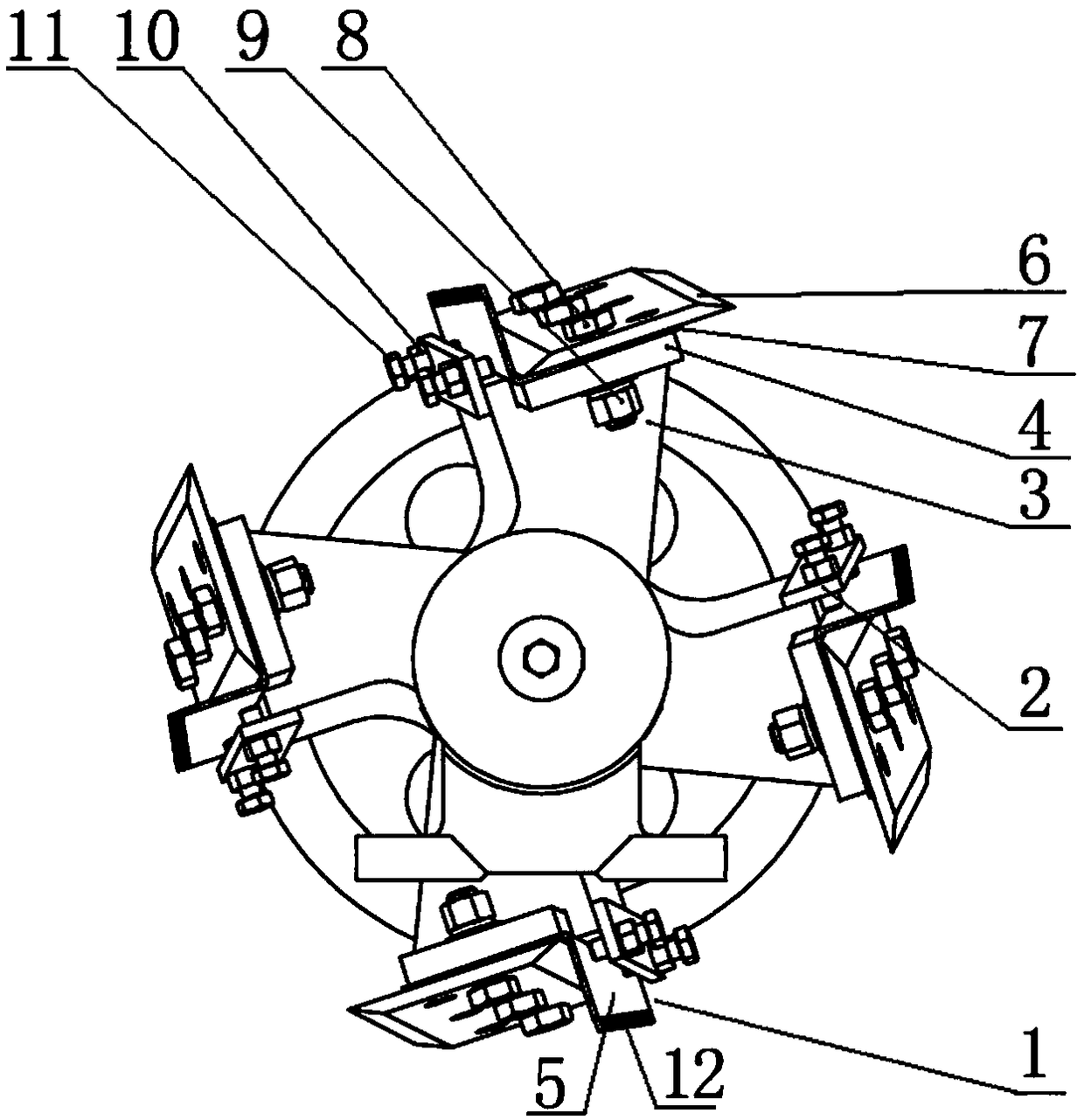

[0014] The utility model relates to a hay cutter provided with a knife-setting adjustment assembly for a guillotine cutter. As shown in the figure is the cutting knife setting adjustment assembly of this mower.

[0015] This guillotine cutter moving knife setting adjustment assembly includes a moving knife 6 and a rotary knife rest 3. In this embodiment, the rotary knife rest 3 is driven by a motor and a belt transmission mechanism for rotary operation.

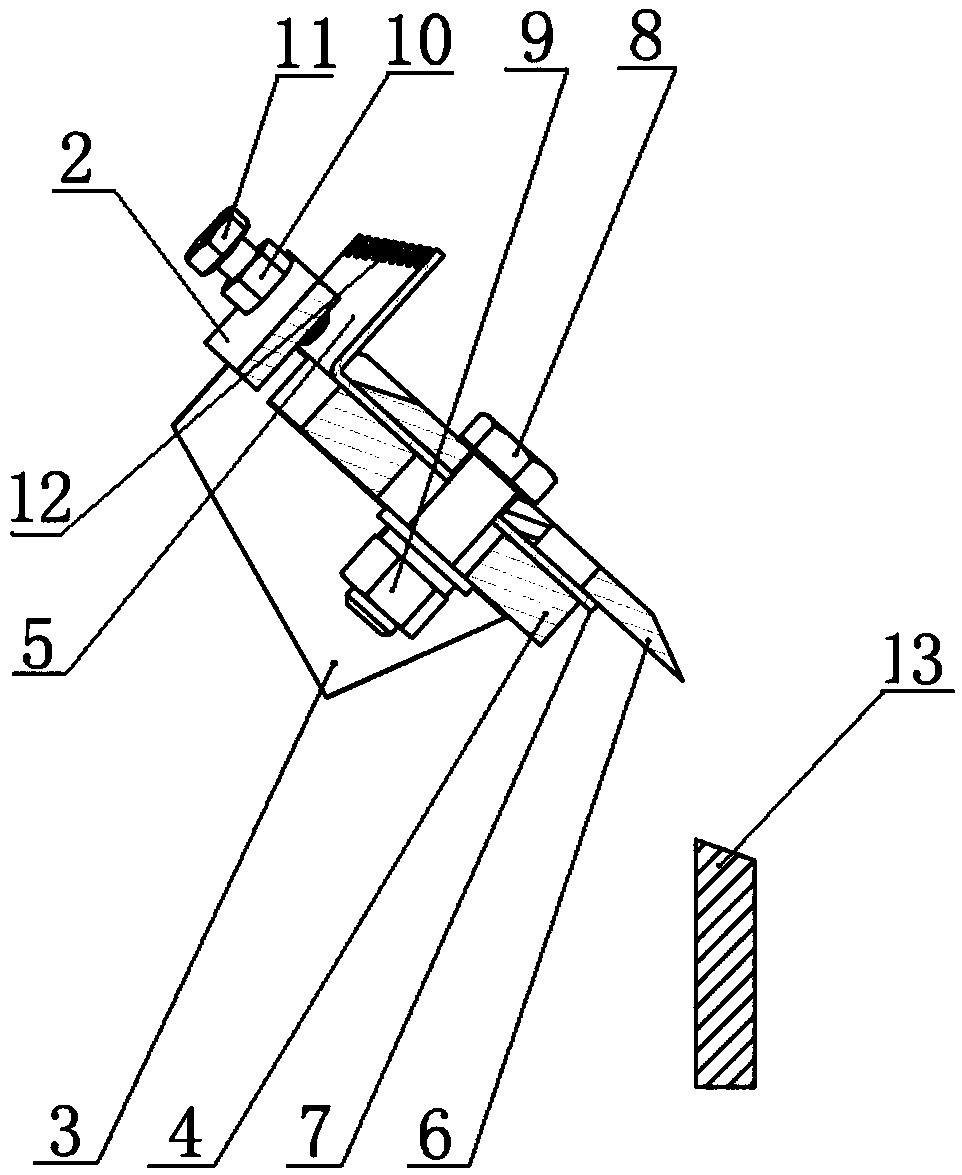

[0016] Described moving knife 6 is double-edged moving knife, when one side blade wears seriously, can turn 180 °, use the other side blade. The movable knife 6 is fixedly installed on the knife seat evenly distributed on the circumference of the rotary knife rest 3 by the fixed bolt 8 and the fixed nut 9. The knife seat is adjusted by the knife seat plate 4 and the vertical knife seat plate 4 at the rear of the knife seat plate 4. Knife seat 2 is formed. This assembly also includes a knife adjustment angle frame 1, the kni...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com