Processing method for ready-to-eat fresh walnuts

A processing method, fresh walnut technology, applied in ultra-high pressure food processing, food preservation, food science, etc., can solve the problems of destroying walnut nutrients and lack of selectivity of consumers, so as to reduce the loss of nutrients, maintain natural flavor, Ease of consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

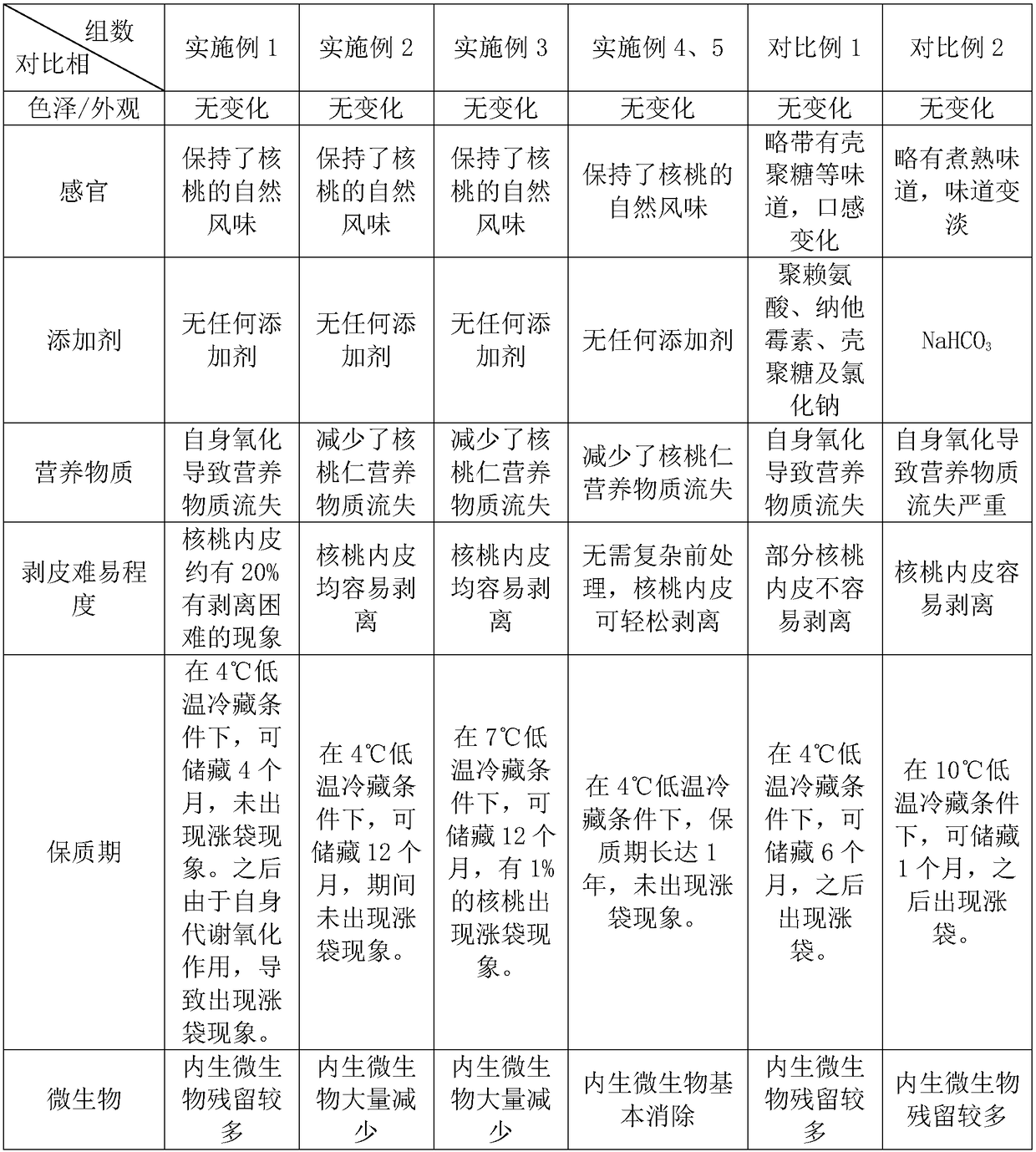

Examples

Embodiment 1

[0020] A processing method of instant fresh walnuts, specifically comprising the following steps:

[0021] 1) Washing and shelling fresh green walnuts to obtain fresh walnut kernels;

[0022] 2) Put fresh walnut kernels into packaging bags, pack them in vacuum, and process them under an ultra-high pressure of 100 MPa for 10 minutes to obtain instant fresh walnut kernel products;

[0023] 3) The instant fresh walnut kernel product obtained in step 2) is stored at a low temperature of 4°C.

Embodiment 2

[0025] A processing method of instant fresh walnuts, specifically comprising the following steps:

[0026] 1) Washing and shelling fresh green walnuts to obtain fresh walnut kernels;

[0027] 2) Put fresh walnut kernels into a packaging bag, vacuum pack, and undergo a pressure treatment of 300 MPa at ultra-high pressure for 5 minutes to obtain an instant fresh walnut kernel product;

[0028] 3) The instant fresh walnut kernel product obtained in step 2) is stored at a low temperature of 4°C.

Embodiment 3

[0030] A processing method of instant fresh walnuts, specifically comprising the following steps:

[0031] 1) Washing and shelling fresh green walnuts to obtain fresh walnut kernels;

[0032] 2) Put fresh walnut kernels into a packaging bag, vacuum pack, and undergo a pressure treatment of 300 MPa at ultra-high pressure for 10 minutes to obtain an instant fresh walnut kernel product;

[0033] 3) The instant fresh walnut kernel product obtained in step 2) is stored at a low temperature of 7°C.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com