Cleaning head for dust collection tool

A technology of cleaning heads and tools, applied in the field of cleaning heads, can solve the problems of reducing the number of replacement cleaning heads, poor cleaning effect of stubborn stains, and reducing secondary pollution of air, so as to reduce the number of replacement cleaning heads and facilitate Enter the dust suction duct and reduce the effect of secondary pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

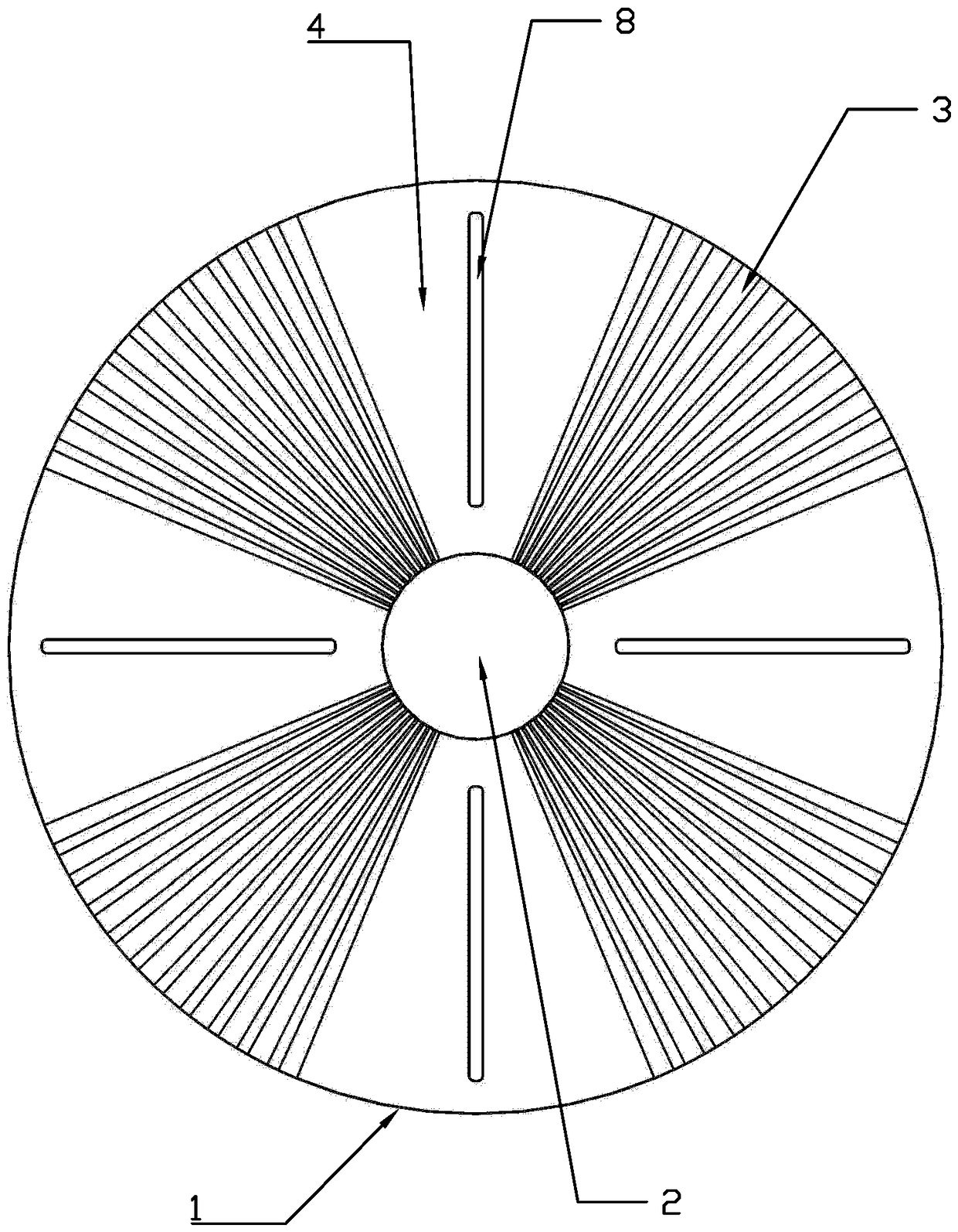

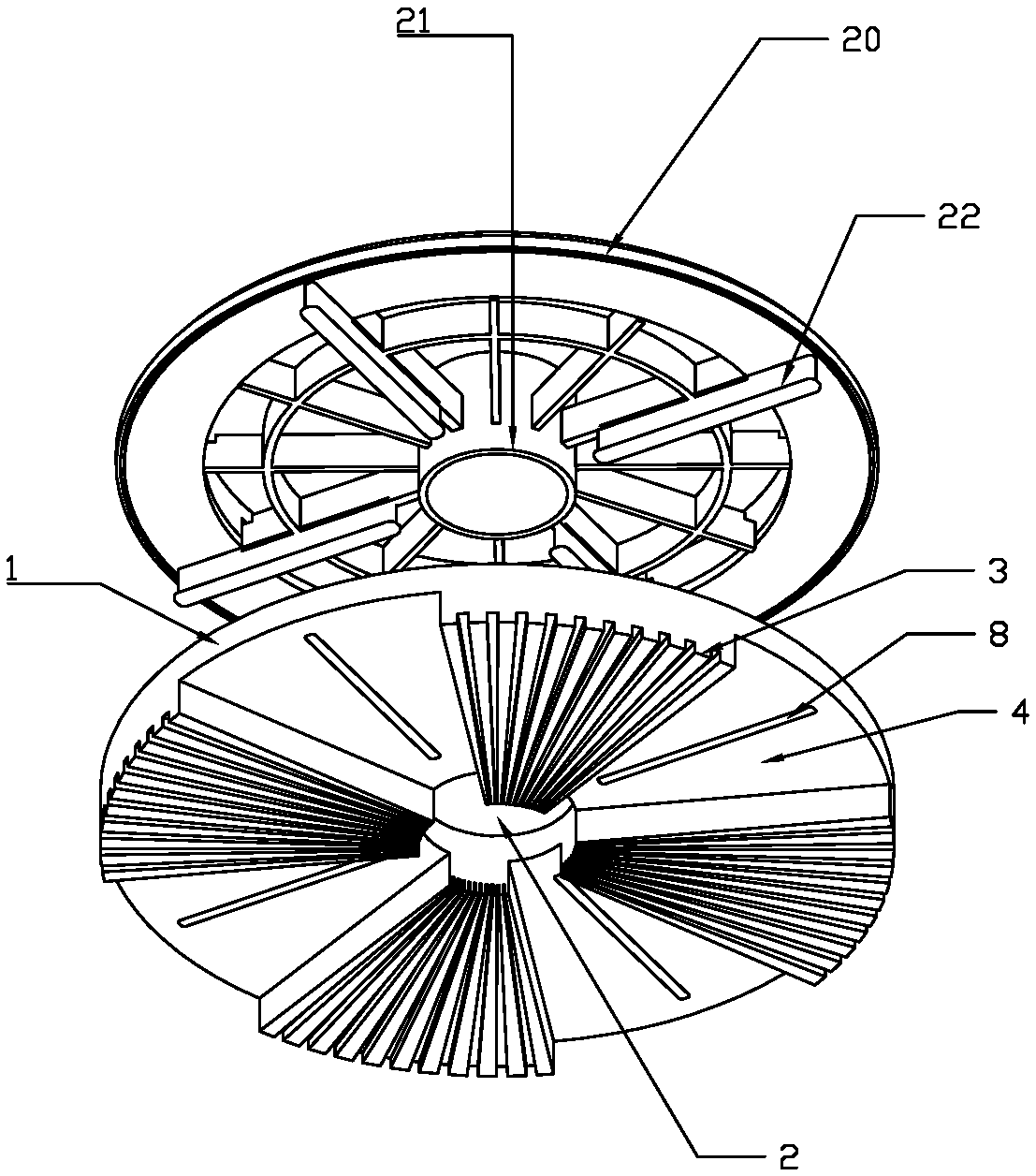

[0022] Embodiment 1: as figure 1 , figure 2 As shown, the cleaning head includes an upper cover 1, the center of the upper cover 1 is provided with a dust suction hole 2, and the lower part of the upper cover 1 is centered on the dust suction hole 2 and is provided with a plurality of radially extending and downward Raised cleaning body 3; in the present embodiment, the lower surface of the cleaning body 3 is preferably fan-shaped, and the cleaning body 3 is made of a flexible wiping material, and the flexible wiping material can be collodion, sponge, fiber fabric or people in the industry Known other flexible materials that can be used for wiping and sweeping the ground, in the present embodiment, upper cover 1 and cleaning body 3 are preferably polyvinyl alcohol collodion foaming materials, and the lower surface of cleaning body 3 is provided with alveolus, adopts mold Integral molding, the upper cover 1 is provided with an installation groove 8 for installation, and the i...

Embodiment 2

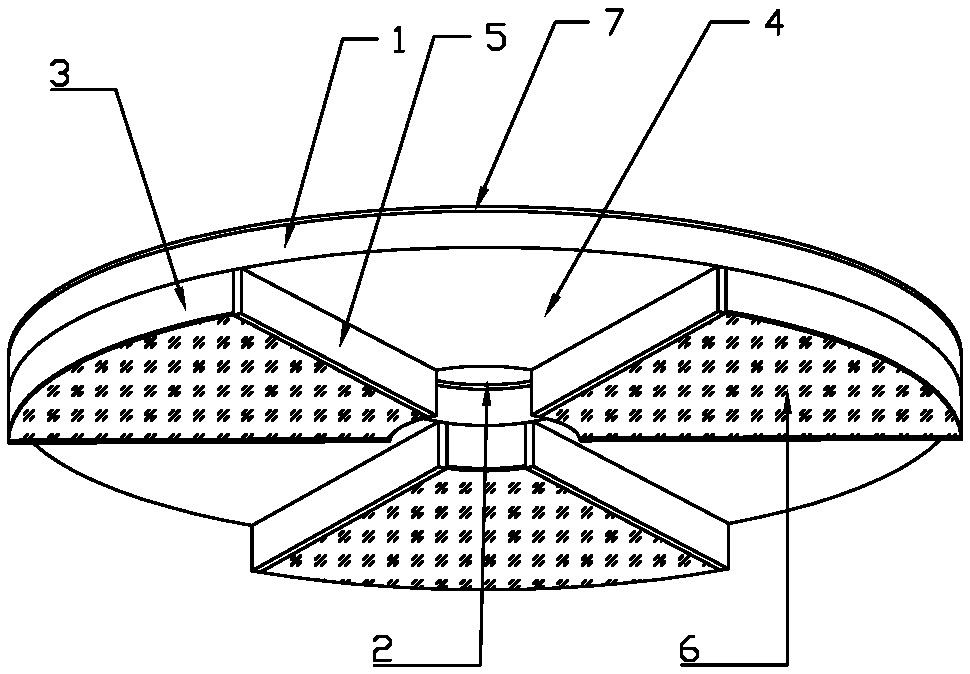

[0023] Embodiment 2: as image 3 As shown, the cleaning head includes an upper cover 1, the center of the upper cover 1 is provided with a dust suction hole 2, and the upper surface of the upper cover 1 is glued or sewn with a Velcro 7, and the Velcro 7 is attached to the bottom of the host during installation. The velcro provided under the installed mounting plate fits together; under the upper cover 1, a plurality of radially extending and downwardly protruding cleaning bodies 3 are arranged at circumferential intervals around the dust suction hole 2, and the cleaning bodies 3 and The upper cover 1 is made of sponge, and the cleaning body 3 and the upper cover 1 can be molded as a whole, or the cleaning body 3 and the upper cover 1 can be glued together, and the lower surface of the cleaning body 3 is glued or sewn with a wiping cloth 6 , on the side of the edge of the cleaning body 3, a scraper 5 is glued, and the scraper 5 can be made of rubber, silica gel or other materia...

Embodiment 3

[0024] Embodiment 3: as Figure 4 As shown, the cleaning head includes an upper cover 1, the center of the upper cover 1 is provided with a dust suction hole 2, and the upper surface of the upper cover 1 is glued or sewn with a Velcro 7, and the Velcro 7 is attached to the bottom of the host during installation. The velcro provided under the installed mounting plate fits together; under the upper cover 1, a plurality of radially extending and downwardly protruding cleaning bodies 3 are arranged at circumferential intervals around the dust suction hole 2, and the cleaning bodies 3 and The upper cover 1 is made of sponge, and the cleaning body 3 and the upper cover 1 can be molded as a whole, or the cleaning body 3 and the upper cover 1 can be glued together, and the lower surface of the cleaning body 3 is glued or sewn with a wiping cloth 6 The part of the lower surface of the cleaning body 3 near the outside has an upwardly tilted slope or curved surface; the lower surface of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com