Broken filament filtering separation device for printing and dyeing equipment

A technology of filtration separation, printing and dyeing equipment, applied in filtration separation, separation methods, fixed filter element filters, etc., can solve problems such as insufficient filtration, achieve the effect of firm separation tank, strengthen sealing, and avoid sewage seepage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

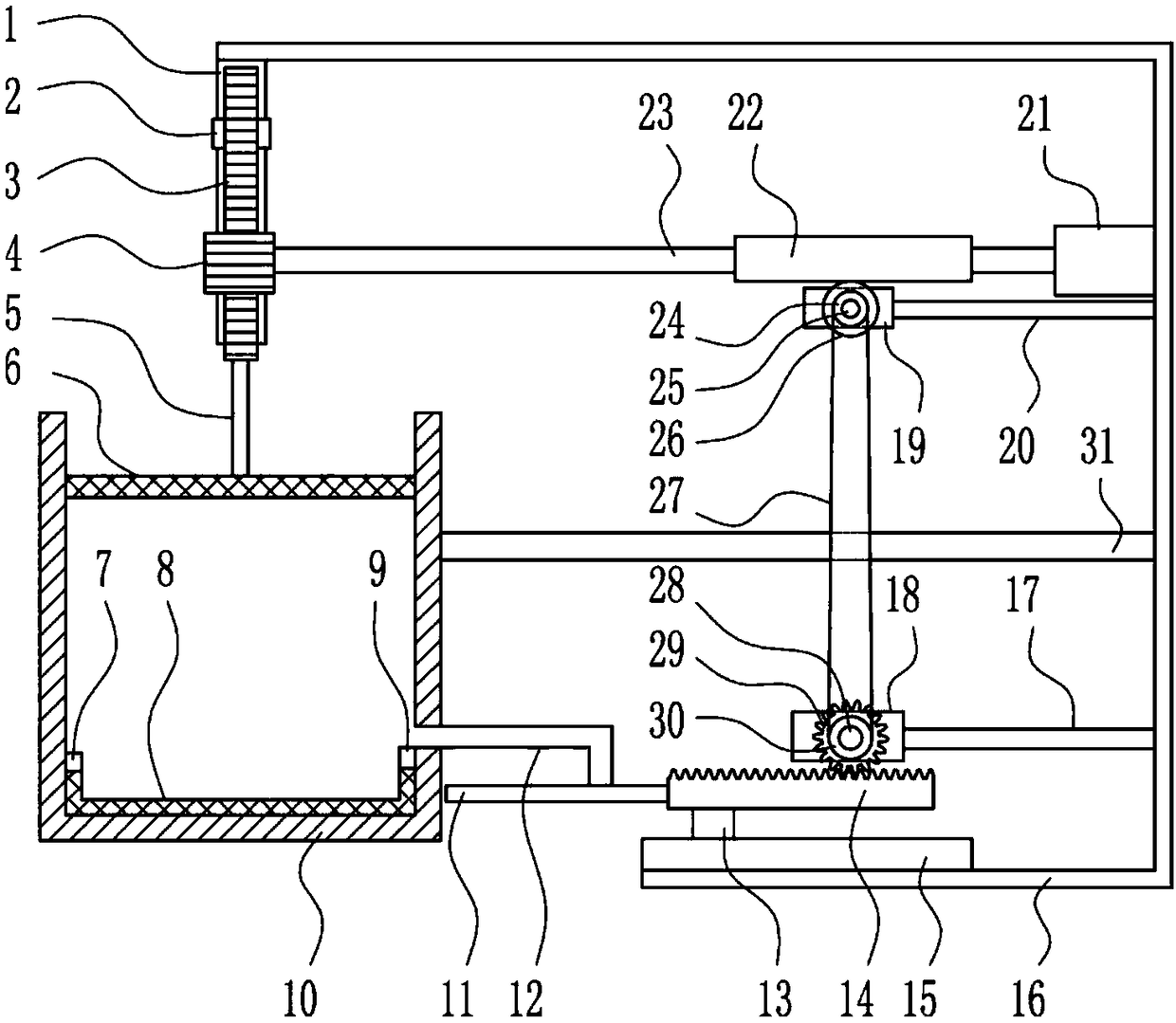

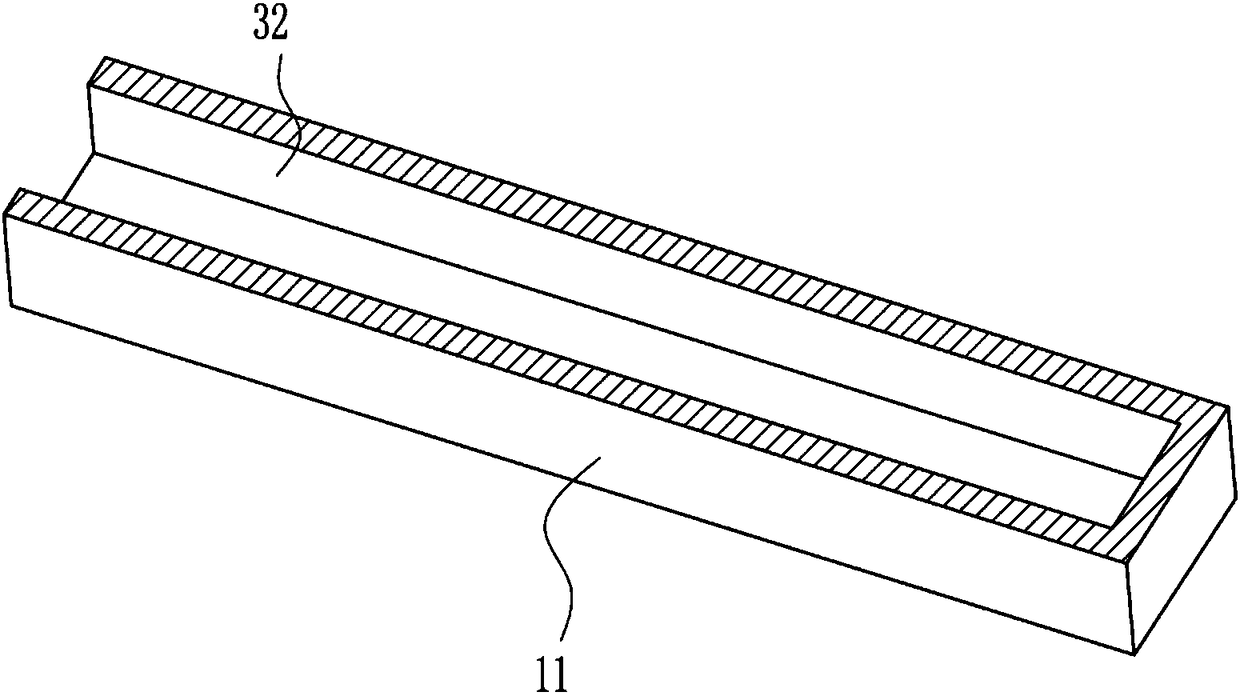

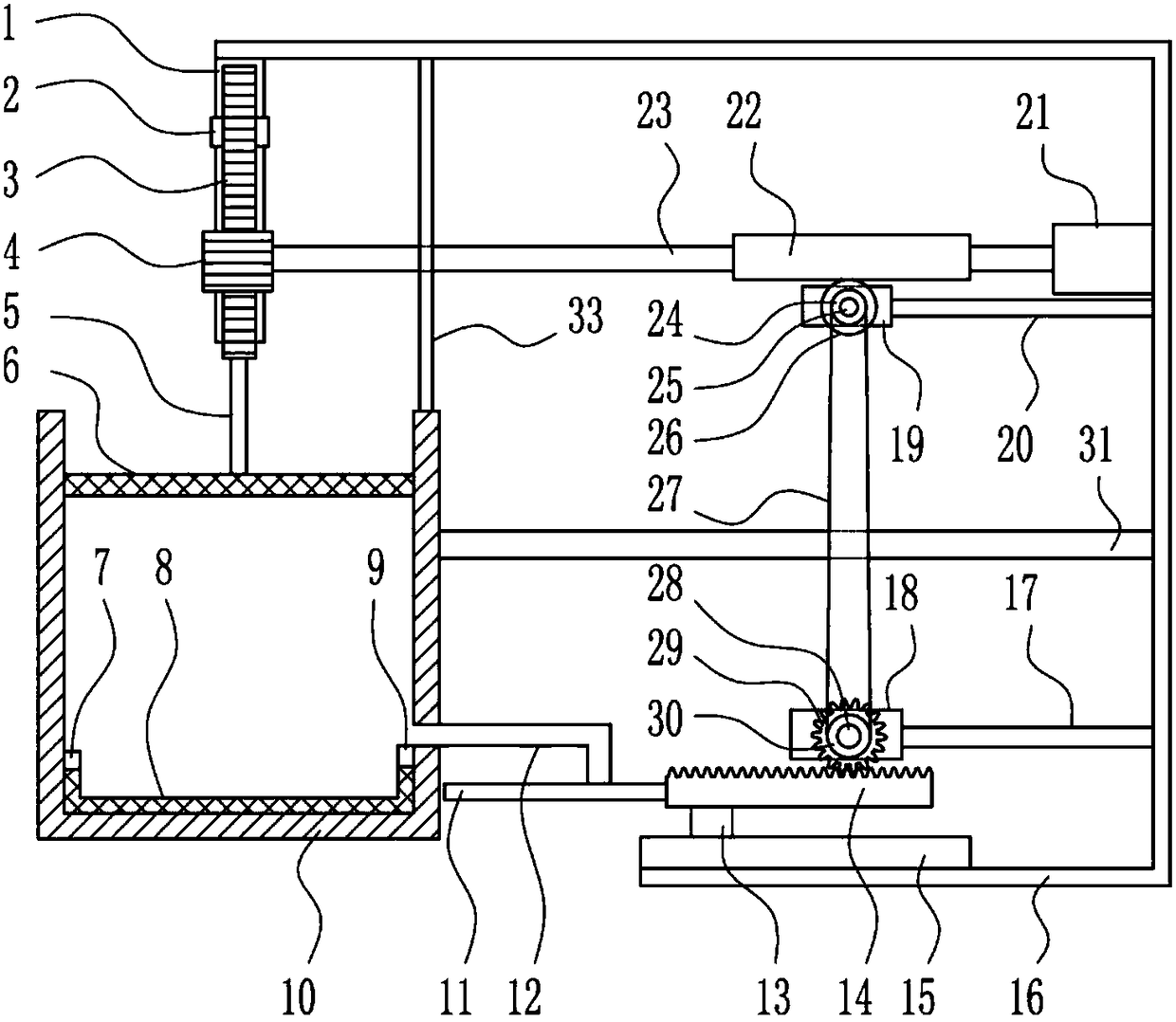

[0037] A wool filter separation device for printing and dyeing equipment, such as Figure 1-6 As shown, it includes the first slide rail 1, the first slider 2, the first rack 3, the first gear 4, the lifting rod 5, the iron filter screen 6, the first magnet 7, the mesh groove 8, the second magnet 9. Separation groove 10, block 11, square water pipe 12, second slider 13, second rack 14, second slide rail 15, bracket 16, lower connecting rod 17, lower bearing seat 18, upper bearing seat 19, Upper connecting rod 20, motor 21, worm screw 22, first rotating shaft 23, small pulley 24, second rotating shaft 25, worm wheel 26, flat belt 27, third rotating shaft 28, second gear 29, large pulley 30 and middle connecting rod 31 The left end of the top of the bracket 16 is welded with a first slide rail 1, the front side of the first slide rail 1 is slidably provided with a first slider 2, and the front side of the first slider 2 is welded with a first rack 3, The bottom of the first rac...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com