Mesoporous nickel catalyst and application of same in polyether amine synthesis

A nickel catalyst and catalyst technology, applied in the field of chemistry and chemical engineering, can solve the problems of low molecular weight universality, irregular pore structure, small specific surface area, etc., and achieve good stability, long service life, and low usage.

Active Publication Date: 2018-11-13

中科榆林能源技术运营有限责任公司

View PDF7 Cites 2 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

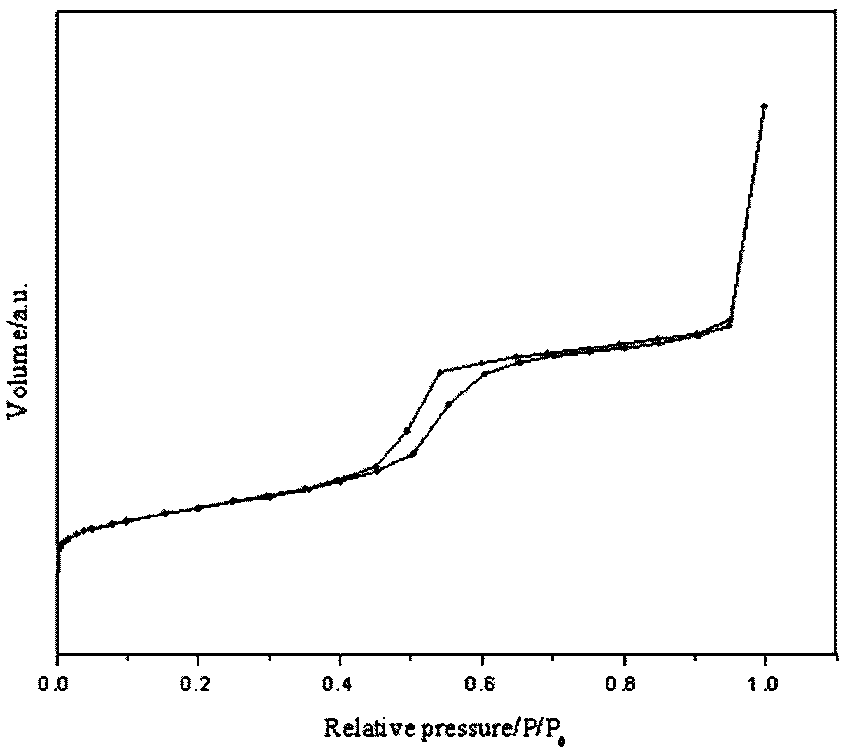

[0003] However, most of the catalysts used so far are commercial Raney series, which have small specific surface area, irregular pore structure, low primary amine rate and low molecular weight universality.

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment Construction

[0016] The method provided by the present invention is described in detail below in conjunction with the examples, but the present invention is not limited in any form.

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

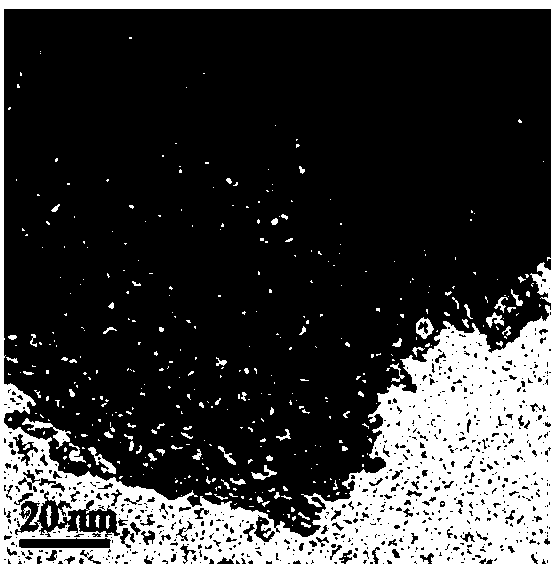

The invention discloses a mesoporous nickel catalyst and application of the same in polyether amine synthesis. According to the catalyst, nickel nitrate serves as a nickel source, a mesoporous structure is formed under the action of surfactants after weak base prehydrolysis, and a mesoporous nickel structure is formed with the presence of reducing agents such as sodium borohydride. The mesoporousnickel catalyst can efficiently catalyze polyether polyol to synthesize polyether amine through hydrogen ammoniation, and the primary amine yield of the polyether polyol with the number-average molecular weight of 200-5000 reaches more than 98%. Compared with conventional skeletal catalysts, the mesoporous nickel catalyst has the advantages of pore uniformity, low consumption, high stability and long service life.

Description

technical field [0001] The invention relates to the field of chemical engineering, in particular to a mesoporous nickel catalyst and its application in polyetheramine synthesis. Background technique [0002] Polyetheramine is a kind of polymer whose main chain is polyether structure and the terminal active functional group is amine group. Because of the adjustability of a series of properties such as polyetheramine reactivity, toughness, viscosity and hydrophilicity, and the amine group provides the possibility of polyetheramine reacting with various compounds, its special molecular structure endows polyetheramine Excellent comprehensive performance, the current commercialized polyetheramines include monofunctional, difunctional, trifunctional, and a series of products with molecular weights from 200 to 5000. It has been widely used in many fields such as polyurea spraying, large composite materials and epoxy resin curing agent. The synthesis methods of polyether amine mai...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More IPC IPC(8): B01J23/755B01J35/10C08G65/00

CPCC08G65/00B01J23/755B01J35/63B01J35/64

Inventor 石松徐杰孙颖杜文强高进刘梦

Owner 中科榆林能源技术运营有限责任公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com