Anti-seismic and wear-resistant stamping mold

A technology of stamping dies and punches, which is applied in the field of anti-seismic and wear-resistant stamping dies, to achieve the effects of simple structure, improved anti-seismic and reasonable design

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

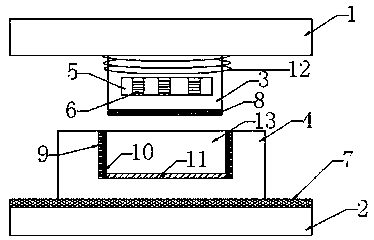

[0017] The invention discloses an anti-vibration and wear-resistant stamping die, comprising: an upper die base 1, a lower die base 2, a punch 3 and a die 4, the punch 3 is fixed on the upper die base 1, and the die base 1 Die 4 is fixed on the said lower mold base 2. The concave mold 4 is provided with a mold cavity 13 capable of cooperating with the male mold 3 .

[0018] The male mold 3 is in interference fit with the mold cavity 13 of the female mold 4 . The bottom surface of the male mold 3 has a layer of ceramic particles 8, the bottom of the cavity 13 on the concave mold 4 has a layer of resin layer 11, and the walls around it have a high-strength elastic composite layer 10 and hard alloy layer 9, wherein the high-strength elastic composite layer 10 is located on the outside of the cemented carbide layer 9. The ceramic particle layer 8 can protect the bottom of the punch well against wear, and the resin layer 11 opposite to the ceramic particle layer 8 can protect the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com