Water spray dedusting system for plasma cutting machines

A technology of plasma cutting machine and dust removal system, which is applied in the field of dust removal equipment, can solve problems such as easy dust, difficult to clean, dust scab, etc., and achieve the effect of improving the quality of the working environment, avoiding air pollution, and keeping clean

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

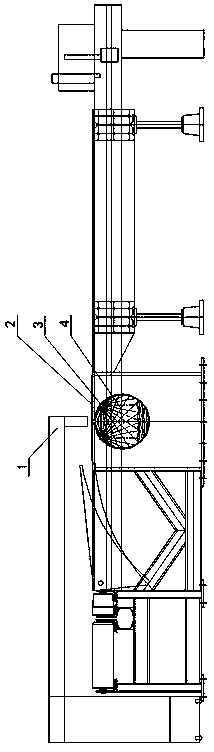

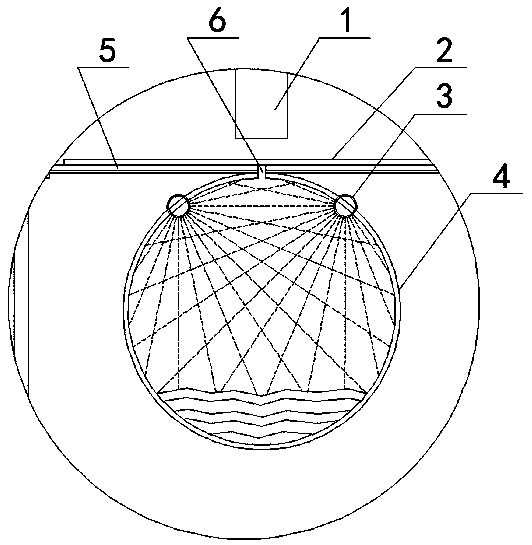

[0023] See attached Figure 1-2 , The water mist dust removal system disclosed in the present invention is a dust removal device used in conjunction with the plasma cutting machine head, and is improved on the basis of the existing plasma cutting machine.

[0024] The water mist dedusting system for a plasma cutting machine includes a plasma cutting machine 1 , a steel plate to be cut 2 , a water mist dedusting nozzle 3 , a water mist dedusting pipeline 4 , a cutting platform 5 , and a cutting groove 6 .

[0025] The water mist dust removal pipeline 4 is set under the cutting platform under the head of the plasma cutting machine through the installation frame, which is not shown in the figure, and the shelf welded with angle iron can be used as a support frame, which is arranged under the cutting platform, mainly used to support the water mist dust remo...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap