Edge grinding machine provided with combined roller grinding wheel

A combined, edging machine technology, applied in machine tools suitable for grinding workpiece edges, parts of grinding machine tools, and grinding machines, can solve the problem of high labor intensity for operators, short service life of grinding wheels, and high edge grinding defect rate. problems, to achieve the effect of reducing edge grinding defects, reducing maintenance costs and improving workpiece quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Example Embodiment

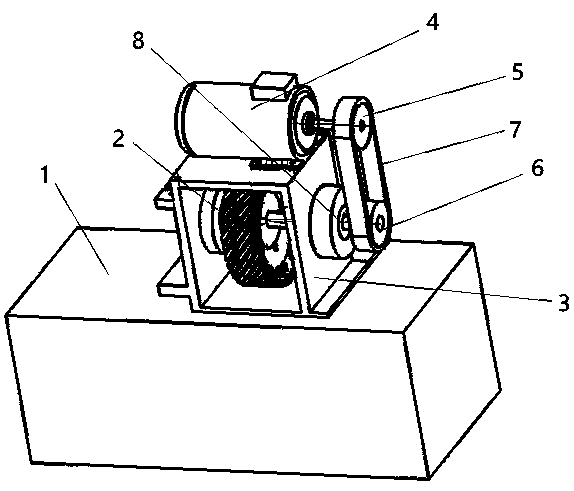

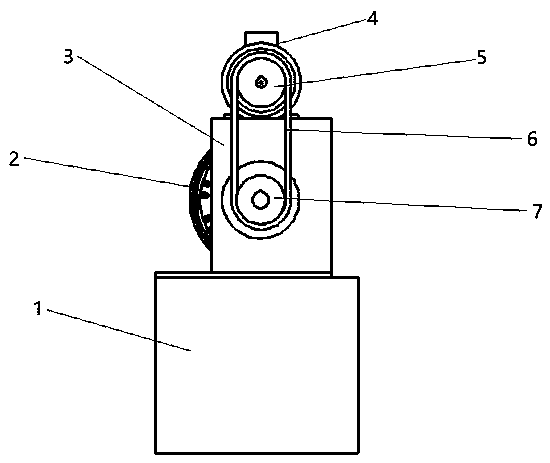

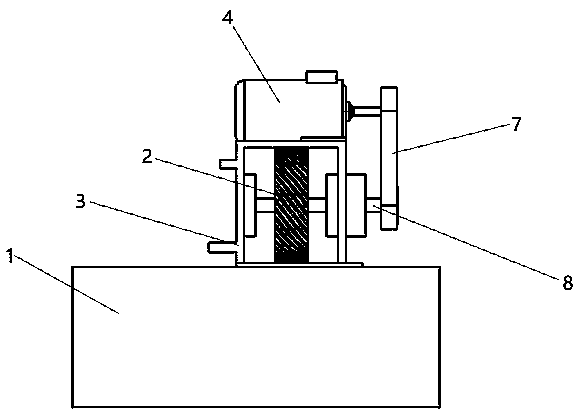

[0015] An edge grinding machine equipped with a combined drum grinding wheel, comprising a beam 1, a combined drum grinding wheel 2, a grinding wheel seat 3, a motor 4, a driving pulley 5, a driven pulley 6, a belt 7 and a rotating shaft 8. The combined drum grinding wheel includes A barrel grinding wheel base 21 and a plurality of grinding wheel blocks; the multiple grinding wheel blocks are fixed on the outer circumference of the barrel grinding wheel base 21 by screws. The grinding wheel seat 3 is installed on the beam 1; the combined drum grinding wheel 2 is installed at the center of the grinding wheel seat 3; the electric motor 4 is installed above the grinding wheel seat 3; the rotating shaft 8 is installed through a bearing On the grinding wheel seat 3, one end of the rotating shaft 8 is connected with the driven pulley 6 and the other end is connected with the combined drum grinding wheel 2. The output shaft of the motor 4 is connected to the driving pulley 5. The bel...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com