Handheld diamond grinding wheel with vibration absorbing function

A diamond and hand-held technology, which is applied in the field of grinding wheels, can solve the problems of hand-held diamond grinding wheels such as trembling and jumping, and achieve the effects of light weight, weight reduction and simplified production process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

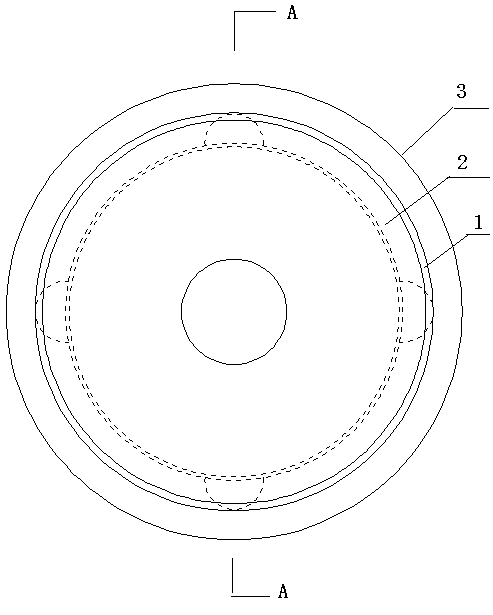

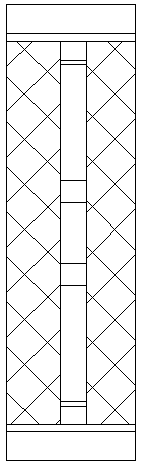

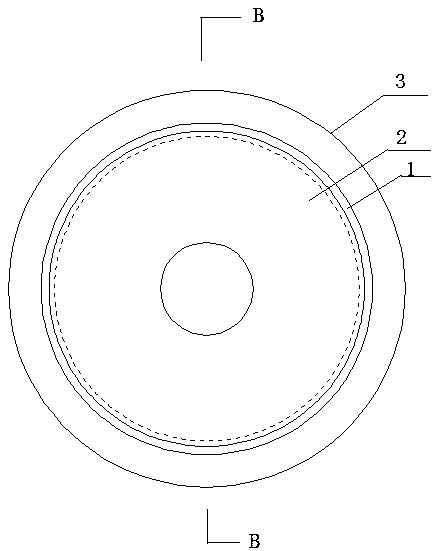

[0012] A hand-held diamond grinding wheel with a shock-absorbing function, comprising a working layer 3 of a grinding wheel composed of diamond abrasives and alloys consolidated, a metal rigid substrate 1, and a shock-absorbing spoke 2 of the grinding wheel. The working layer 3 of the grinding wheel is driven by the power of the grinder to produce high-speed relative motion with the workpiece to be ground, so as to achieve the effect of grinding. The metal rigid matrix exists in the form of a metal rim, and the outer circular surface and both sides of the rim The diamond nails are welded on the three faces with an alloy on the end face, and the diamond will cut the metal to be ground when the rim rotates. The shock-absorbing spoke 2 of the grinding wheel adopts flexible spokes, and the metal rigid substrate 1 is a structural form of a metal rim. The damping spoke 2 of the grinding wheel is installed in the hollow structure of the spoke surface of the grinding wheel, and the res...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com