Jewel-crafting worktable

A workbench and jewelry technology, applied in the direction of workbench, manufacturing tools, etc., can solve the problems that jewelry processing workbench cannot meet people’s needs, easy to accumulate large debris, and inconvenient to pick and place tools, so as to achieve convenient classification and placement, Reasonable use of space, convenient and quick effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

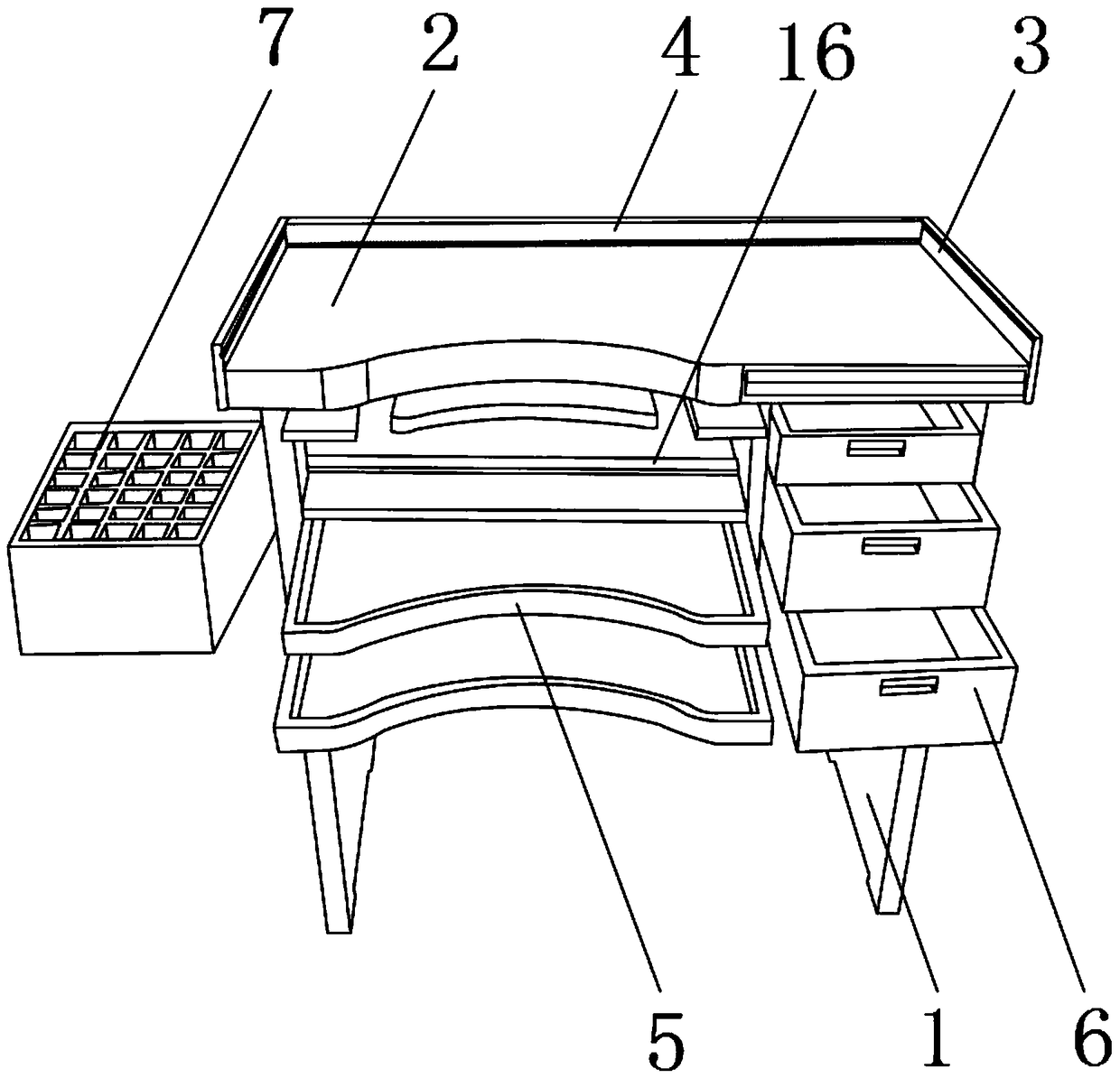

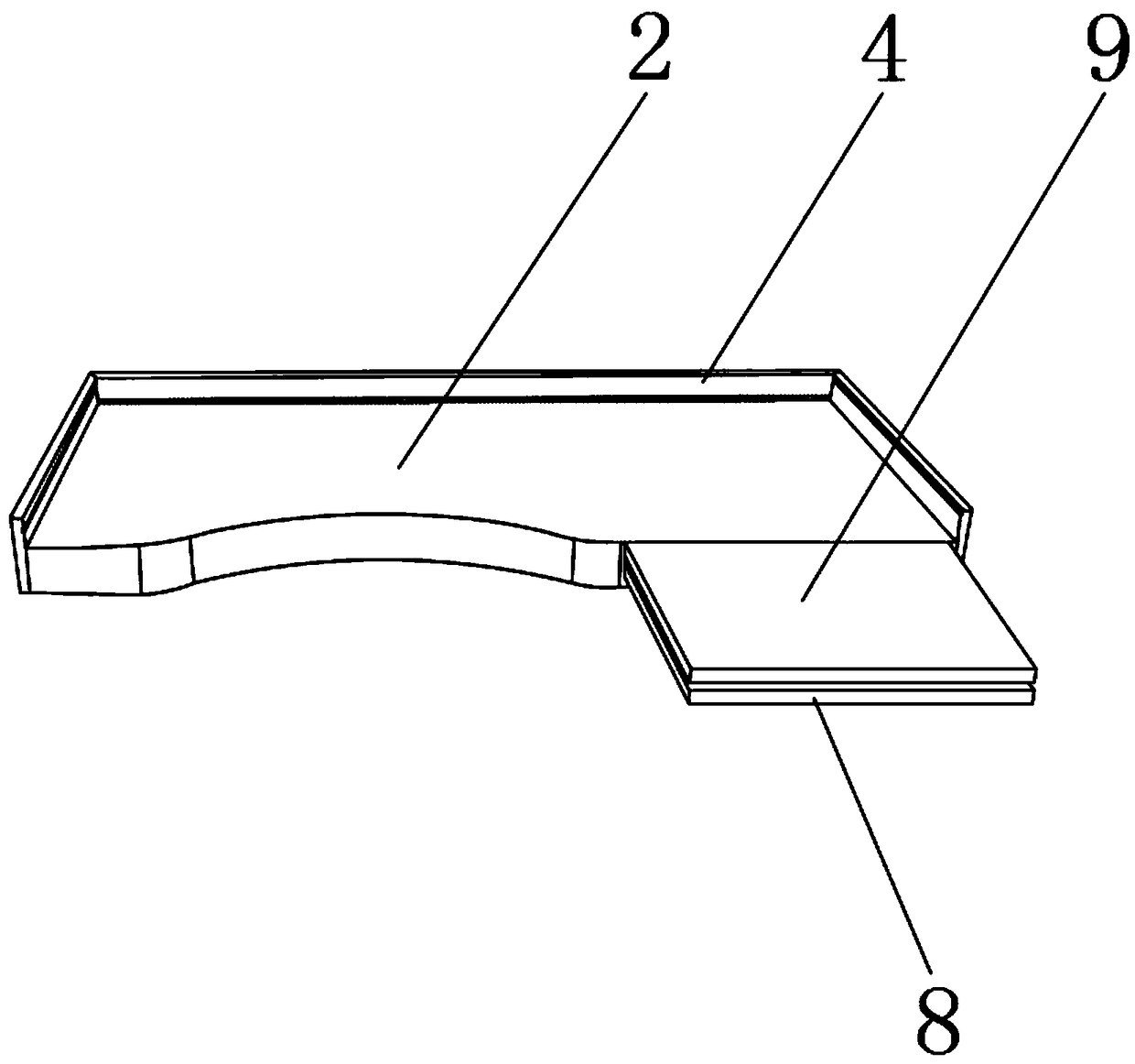

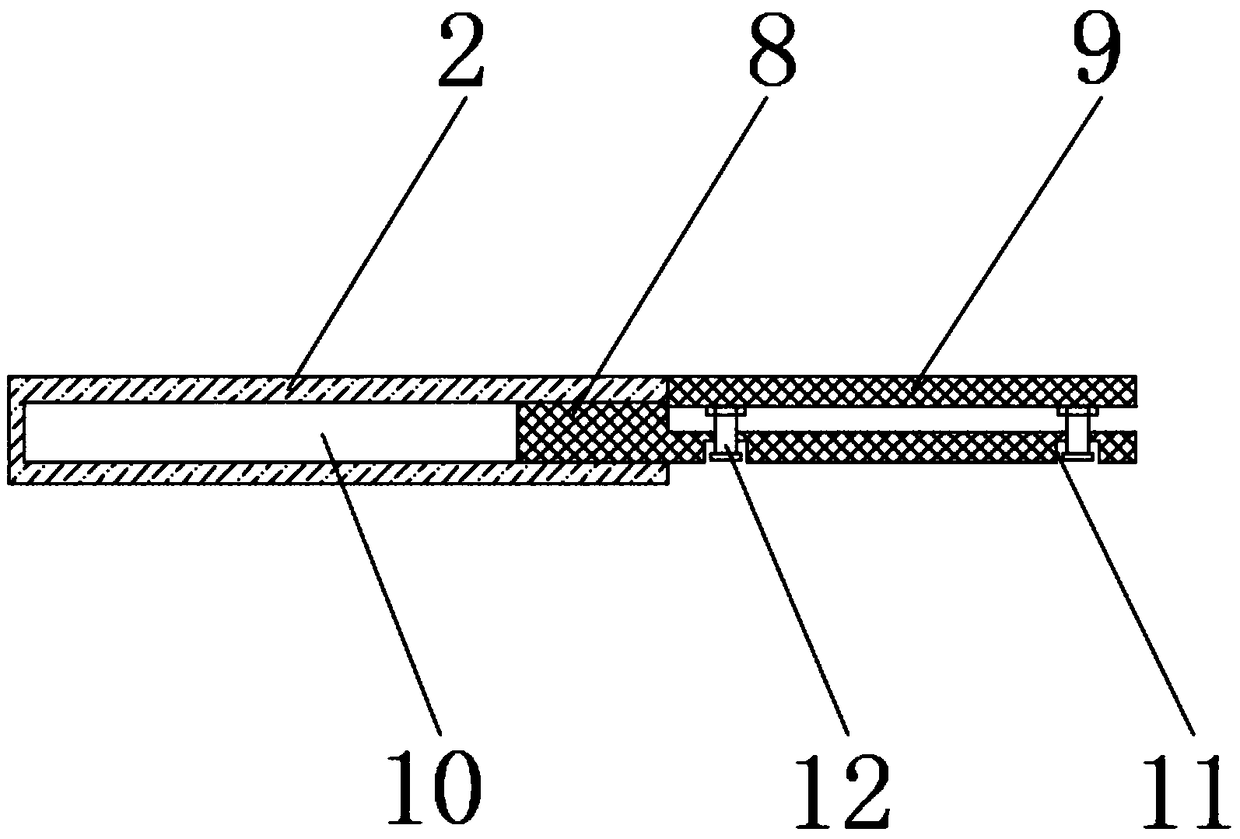

[0026] Such as Figure 1-5 As shown, including the support frame 1, the top outer surface of the support frame 1 is fixed with the workbench 2 by bolts, and the top outer surface of the workbench 2 is fixed with protective side plates 3 by bolts near the two sides, and the two sets of protective side plates A movable plate 4 is movably installed between the 3, and the inside of the support frame 1 near the front end is movably installed with a placement plate 5 and a drawer 6 through slide rails, and the drawer 6 is located on one side of the placement plate 5, and one side of the support frame 1 is outside. The surface is provided with a placement box 7 near the top position, and the inside of the workbench 2 is provided with a guide groove 10 near the front end, and the inner bottom surface of the guide groove 10 is movably installed with a support base plate 8 through slide rails, and the top outer surface of the support base plate 8 is movably installed. There is a connect...

Embodiment 2

[0030] Such as Figure 1-5 As shown, including the support frame 1, the top outer surface of the support frame 1 is fixed with the workbench 2 by bolts, and the top outer surface of the workbench 2 is fixed with protective side plates 3 by bolts near the two sides, and the two sets of protective side plates A movable plate 4 is movably installed between the 3, and the inside of the support frame 1 near the front end is movably installed with a placement plate 5 and a drawer 6 through slide rails, and the drawer 6 is located on one side of the placement plate 5, and one side of the support frame 1 is outside. The surface is provided with a placement box 7 near the top position, and the inside of the workbench 2 is provided with a guide groove 10 near the front end, and the inner bottom surface of the guide groove 10 is movably installed with a support base plate 8 through slide rails, and the top outer surface of the support base plate 8 is movably installed. There is a connect...

Embodiment 3

[0034] Such as Figure 1-5 As shown, including the support frame 1, the top outer surface of the support frame 1 is fixed with the workbench 2 by bolts, and the top outer surface of the workbench 2 is fixed with protective side plates 3 by bolts near the two sides, and the two sets of protective side plates A movable plate 4 is movably installed between the 3, and the inside of the support frame 1 near the front end is movably installed with a placement plate 5 and a drawer 6 through slide rails, and the drawer 6 is located on one side of the placement plate 5, and one side of the support frame 1 is outside. The surface is provided with a placement box 7 near the top position, and the inside of the workbench 2 is provided with a guide groove 10 near the front end, and the inner bottom surface of the guide groove 10 is movably installed with a support base plate 8 through slide rails, and the top outer surface of the support base plate 8 is movably installed. There is a connect...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com