Modularized joint of cooperative positioning arm for minimally invasive surgery robot

A modular joint and cooperative positioning technology, applied in the field of medical robots, can solve the problems of inability to collect control and safety detection data in real time, threats to the personal safety of medical staff, and inability to control the output torque and movement speed of the robotic arm. The effect of high precision, light weight and large output torque

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

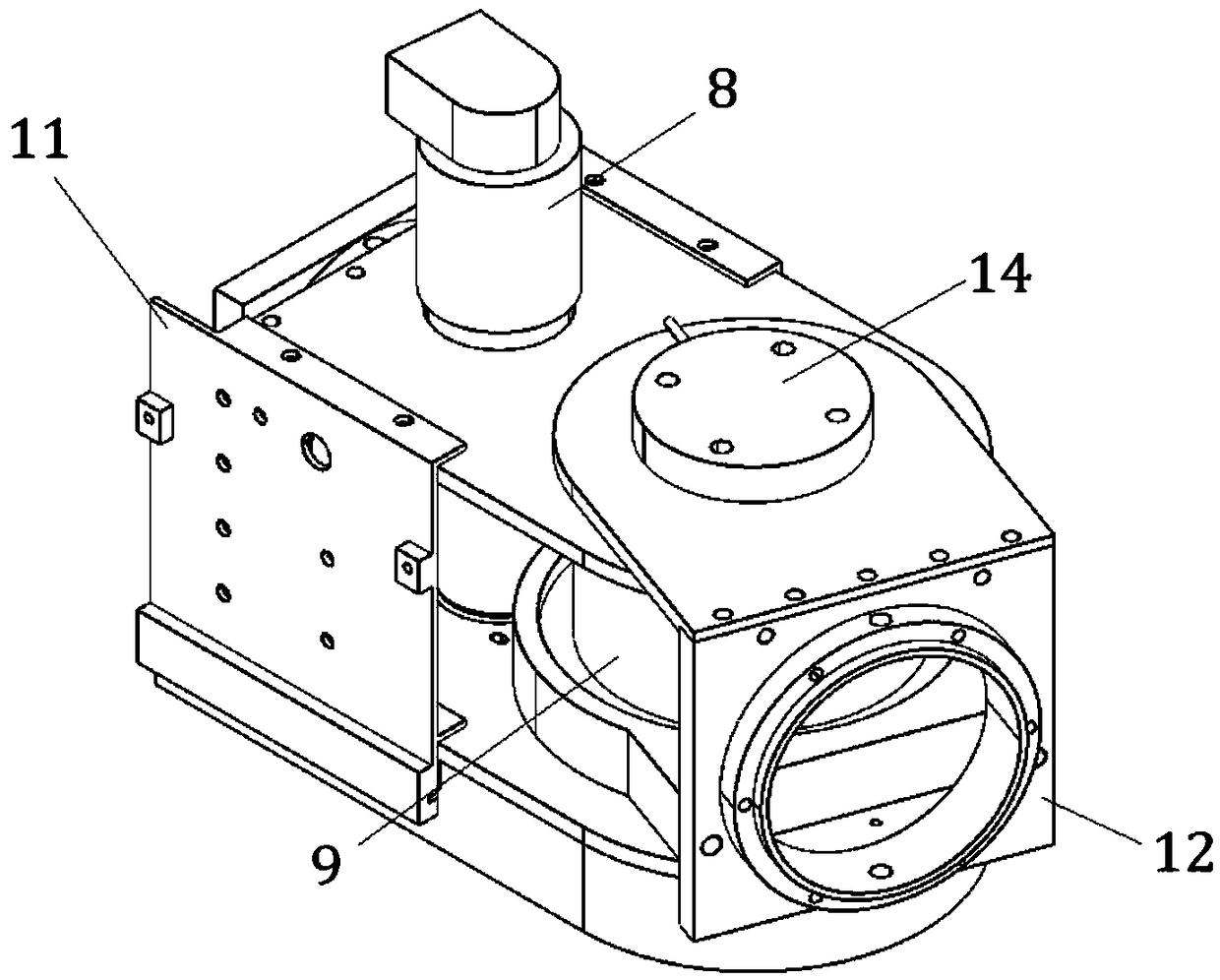

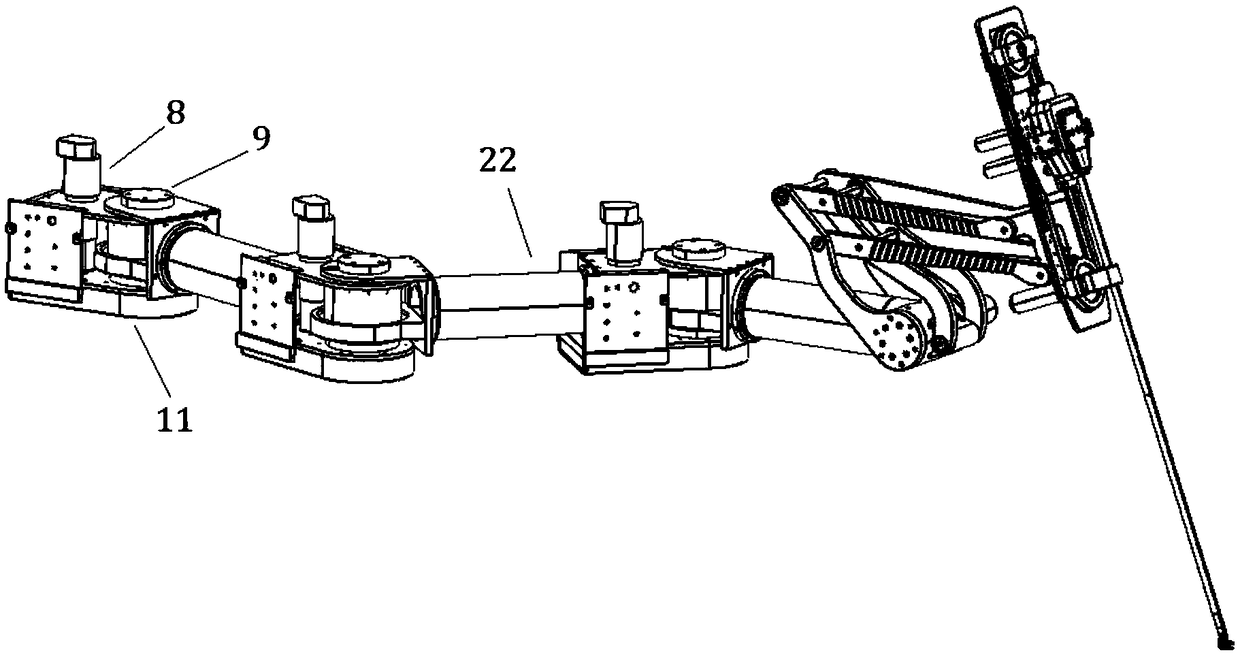

[0018] like figure 1 As shown, it is a modular joint of a cooperative positioning arm for minimally invasive surgery related to this embodiment, including: a housing 11, a driving mechanism 8 fixedly arranged in the housing 11, and an output mechanism 9 rotatably arranged in the housing , wherein: the driving mechanism 8 is connected to the output mechanism 9, the driving mechanism 8 is connected to the output mechanism 9 or the frame of other modular joints, and the output mechanism 9 is connected to the driving mechanism 8 or mechanical claws of other modular joints.

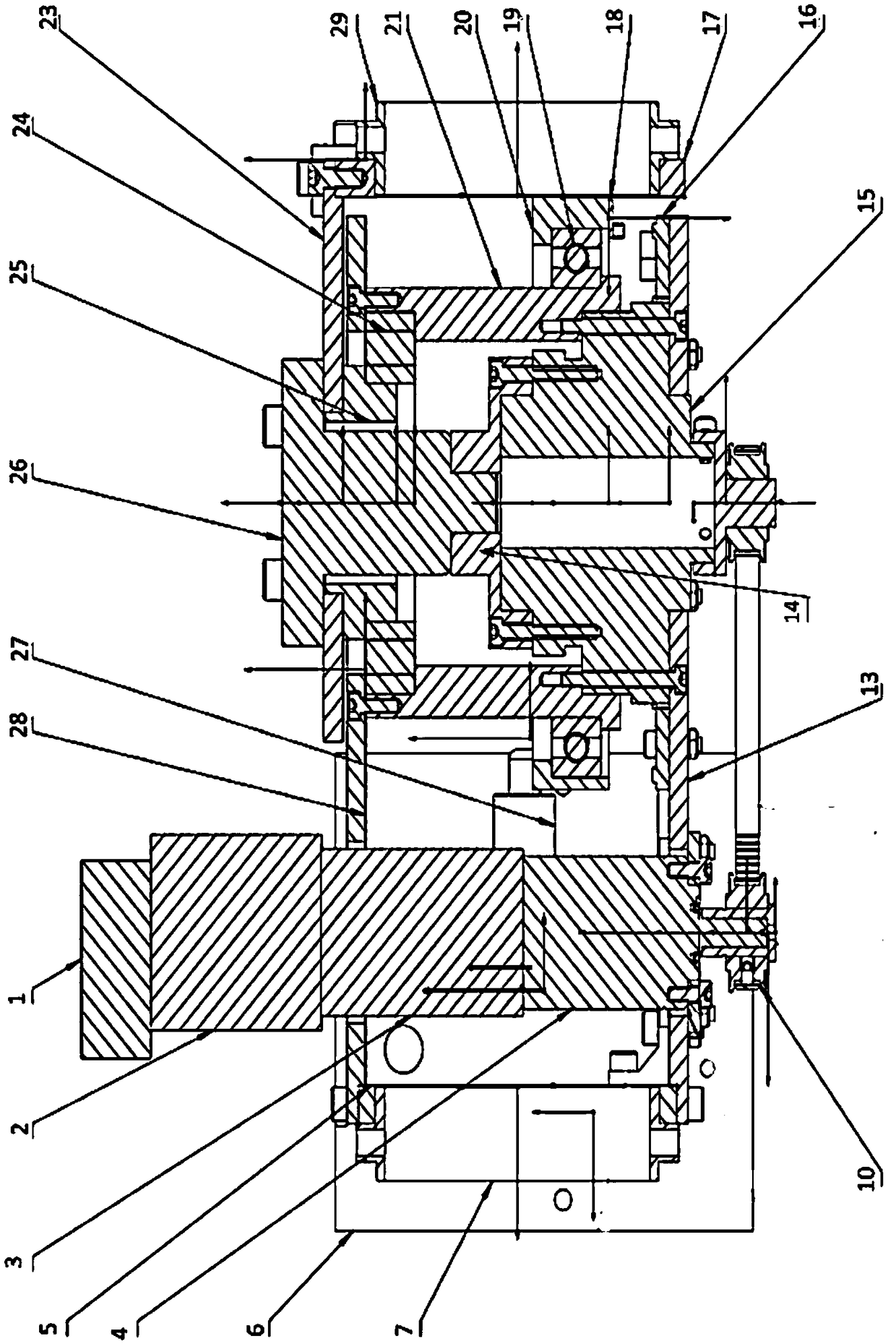

[0019] like figure 2 As shown, the drive mechanism 8 includes: a motor 3 with an encoder 1 and a brake 2, a planetary gearbox 4 connected to the output shaft of the motor, and a synchronous pulley 10 arranged on the output shaft of the planetary gearbox. Wave deceleration mechanism, wherein: the synchronous pulley 10 is connected with the output mechanism 9.

[0020] The output mechanism 9 includes: a torqu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com