Silt-subgrade sluice foundation construction method

A technology for foundation construction and silt foundation, which can be used in infrastructure engineering, construction, etc., to solve problems such as hindering cement hydration reaction, non-binding, and poor dispersion resistance, so as to reduce the risk of taking away and dilution, and accelerate curing. The effect of high speed and compressive strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

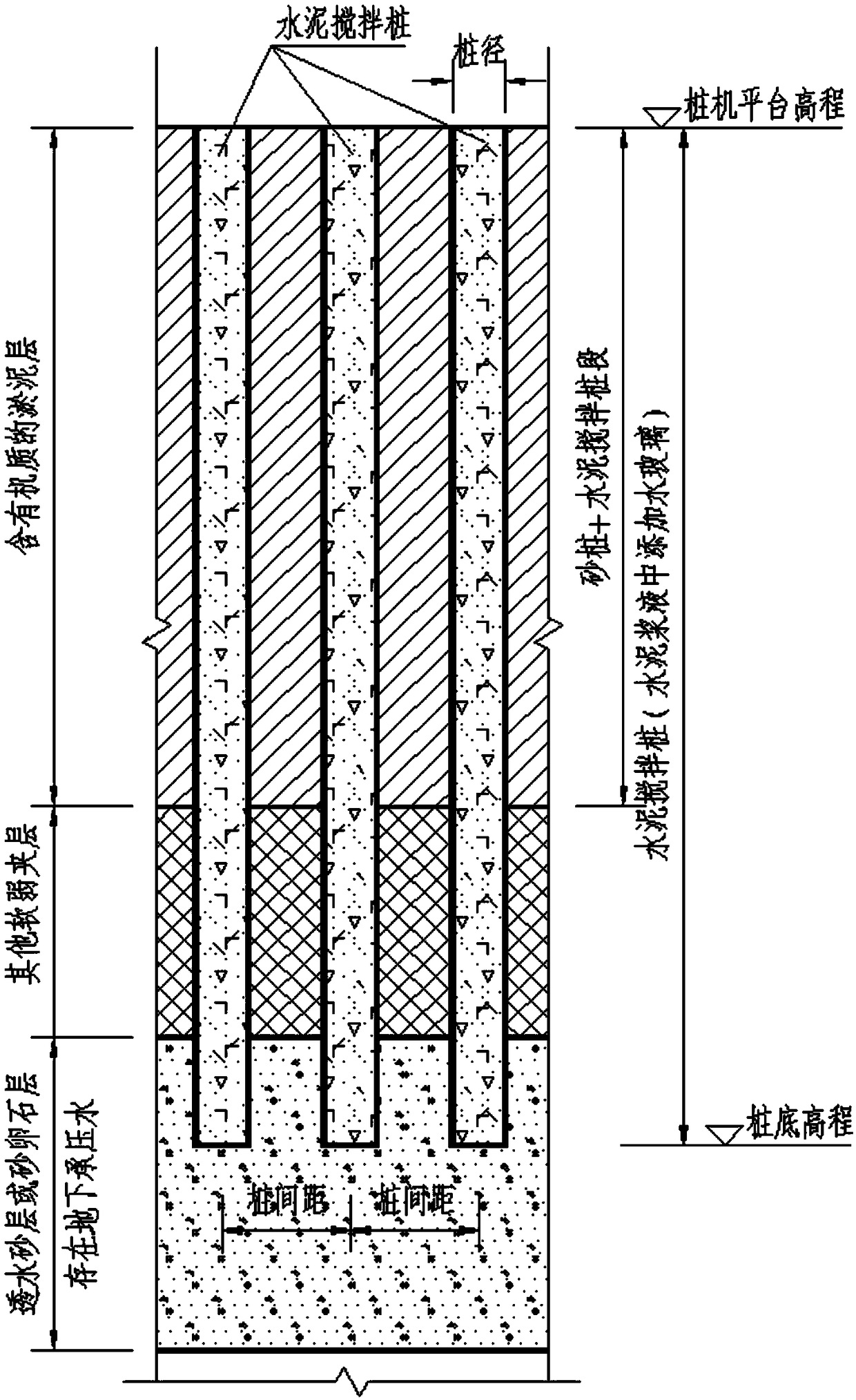

[0021] The present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

[0022] A construction method for a sluice foundation on a silt foundation, comprising:

[0023] Use sand piles to replace the silt around the piles where the mixing piles are to be placed;

[0024] Cement added with water glass is used as a curing agent, which is hardened after being mixed with sand to form a cement mixing pile.

[0025] figure 1 It shows the foundation structure of the Baoshui gate formed after the construction method is completed. The sand pile replaces the silt at the position of the cement mixing pile. The sand pile preferably only needs to penetrate the silt layer, so that a physical and chemical reaction occurs between the cement mixing slurry and the sand, resulting in good cementation, good integrity, and compressive strength. High cement mixing pile; adding water glass quick-setting agent to the cement slu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com