A hydraulically driven high-pressure pulse fluid output device and its operating method

A high-pressure pulse, hydraulic drive technology, used in hydraulic mining, earth-moving drilling, special mining, etc., can solve the problems of unstable flow output, small amplitude of fluid pulse pressure, uncontrollable pulse frequency, etc., and achieve reasonable transformation and utilization. , High frequency adjustment accuracy, and the effect of broadening the utilization methods

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0042] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

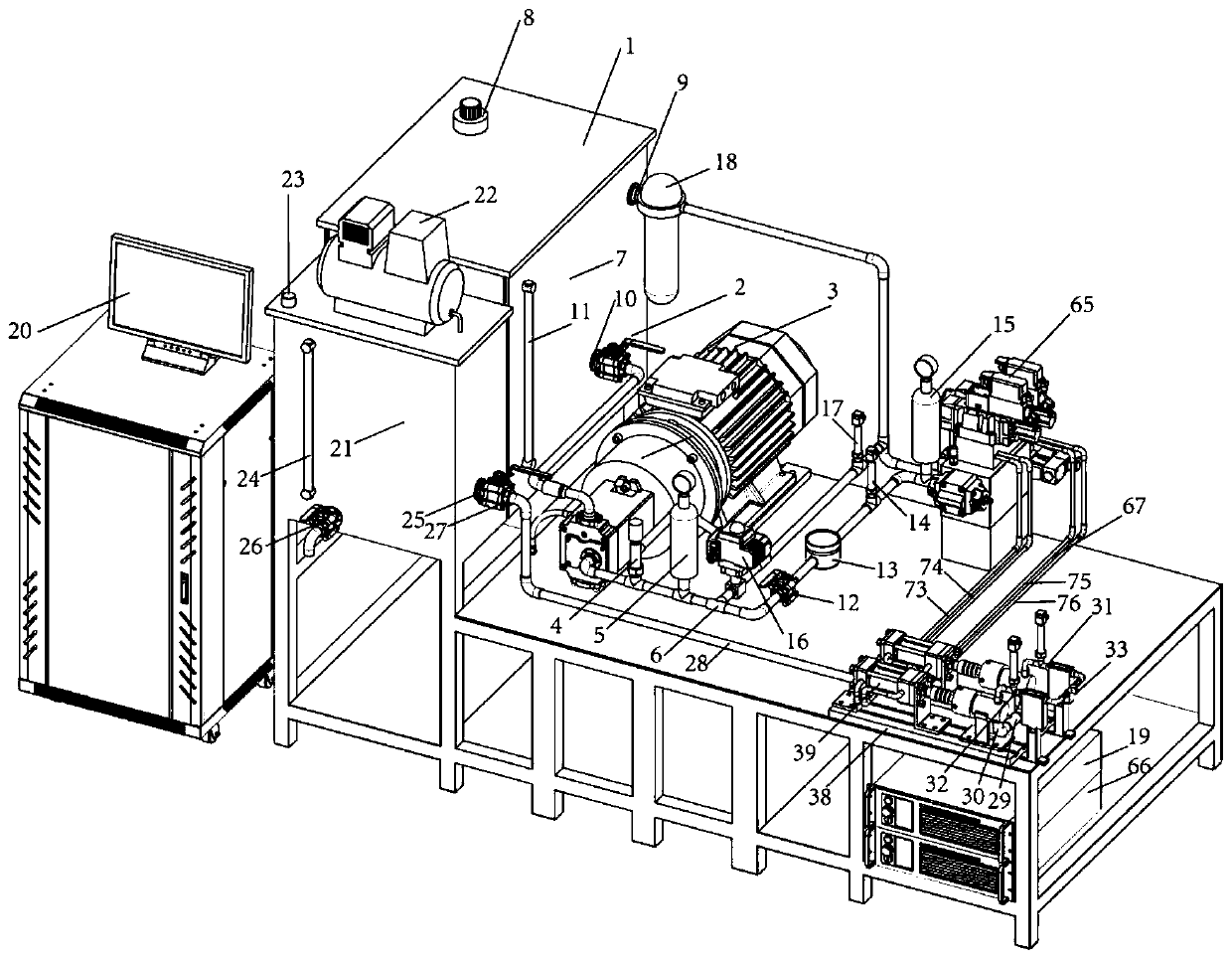

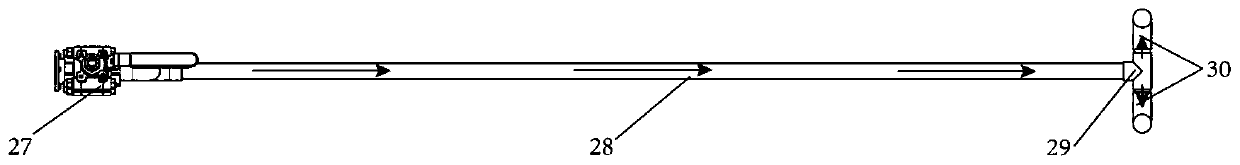

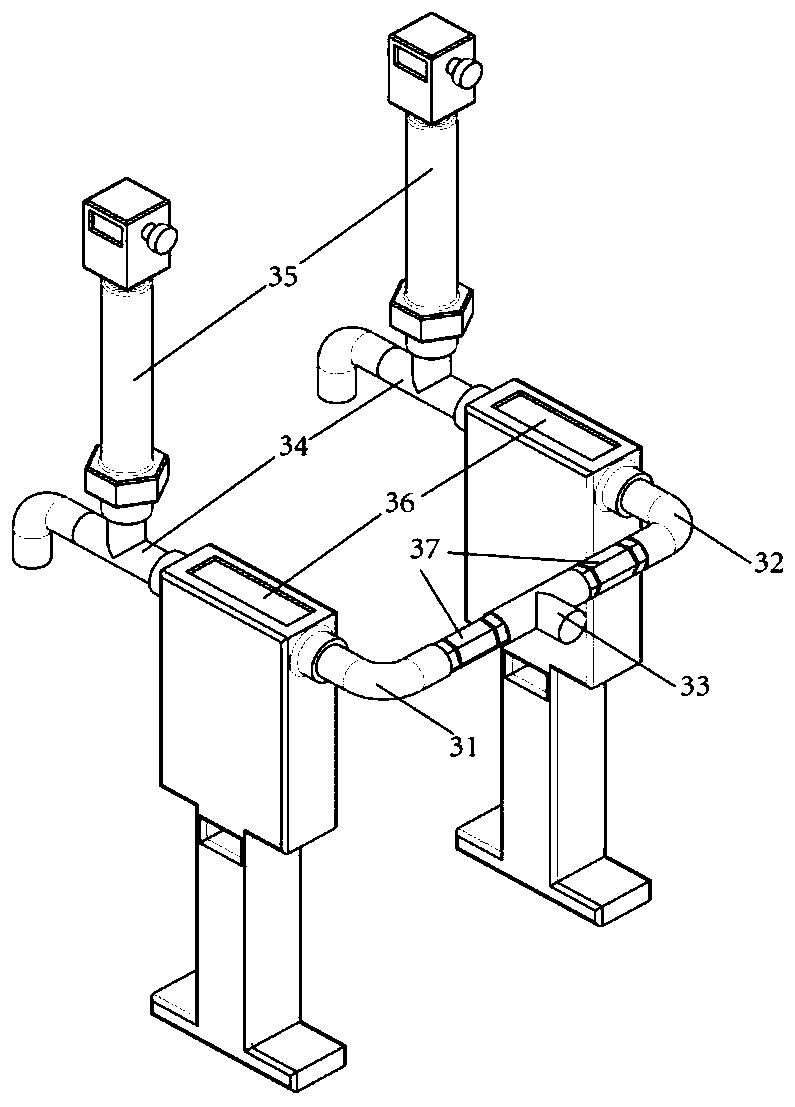

[0043] see Figure 1-Figure 11, a hydraulically driven high-pressure pulse fluid output device, including a pump source device, a fracturing fluid supply device, two sets of fluid pulse generators and a servo control system arranged in parallel with the same structure, the pump source device is used to store water and supply water Provide pressure to simulate deep medium pressure and large flow hydraulic conditions; the fracturing fluid supply device is used to provide continuous low pressure fracturing fluid; the fluid pulse generation device uses the medium pressure and large flow water output by the pump source device as the power The cleavage fluid is transformed into a high-pressure pulse fluid output; the servo control system is electrically connected with two sets of fluid pulse generating devices to control the two sets of fluid pulse g...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com