Hydraulic turbocharged engine with automatic start-stop

A turbocharger, engine technology, applied in the direction of engine components, combustion engines, engine control, etc., can solve the problems of increasing the cost, weight and complexity of vehicle systems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

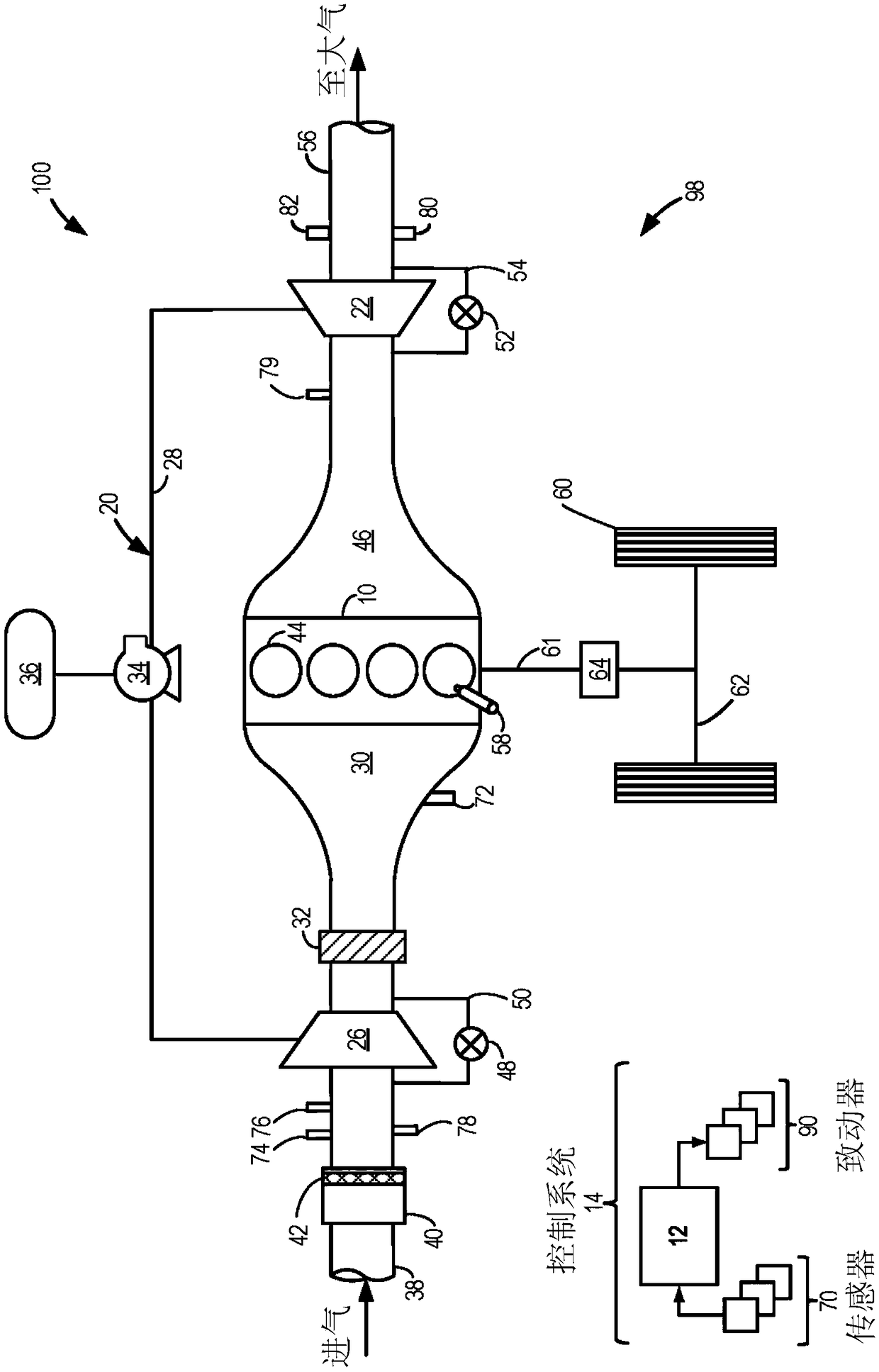

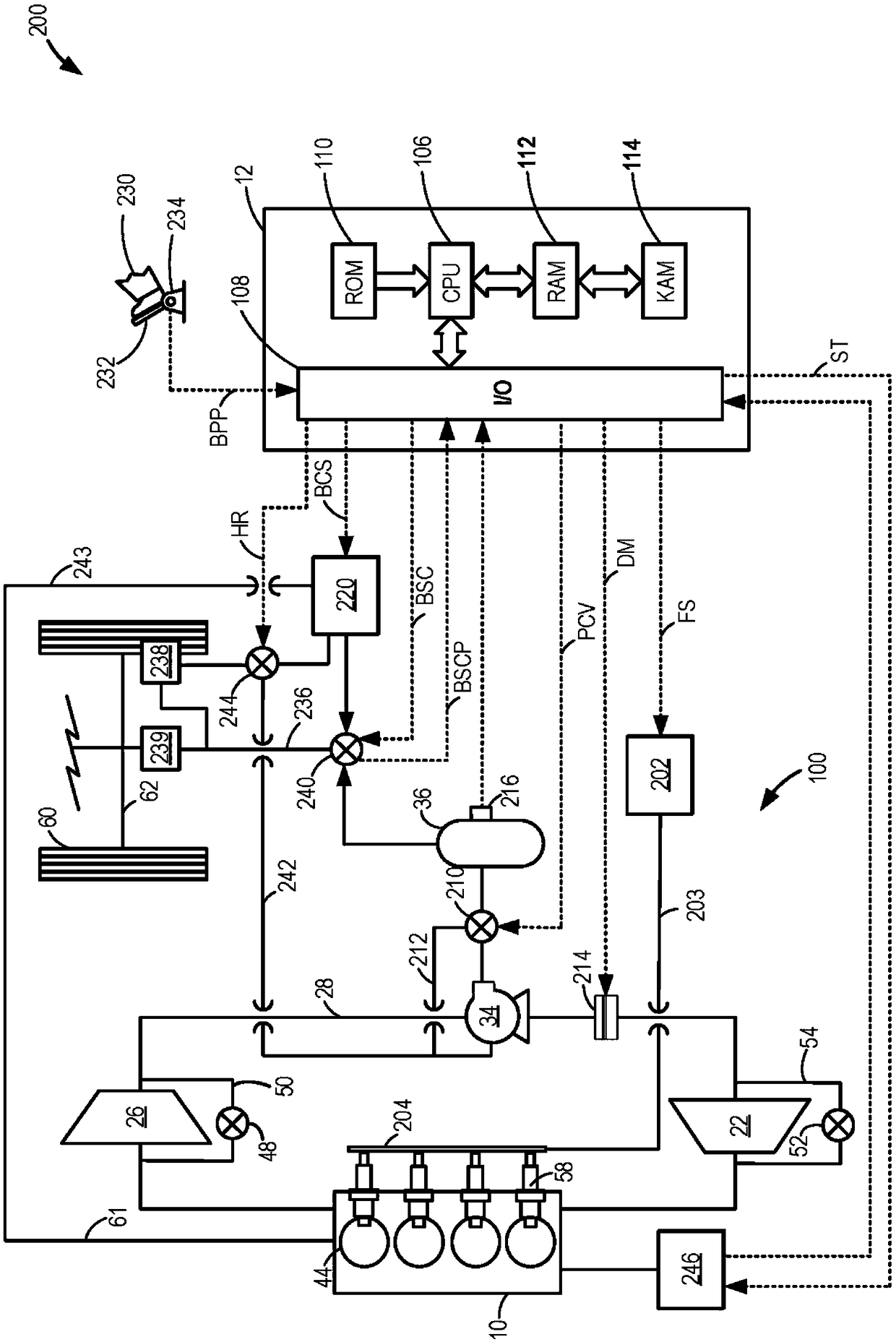

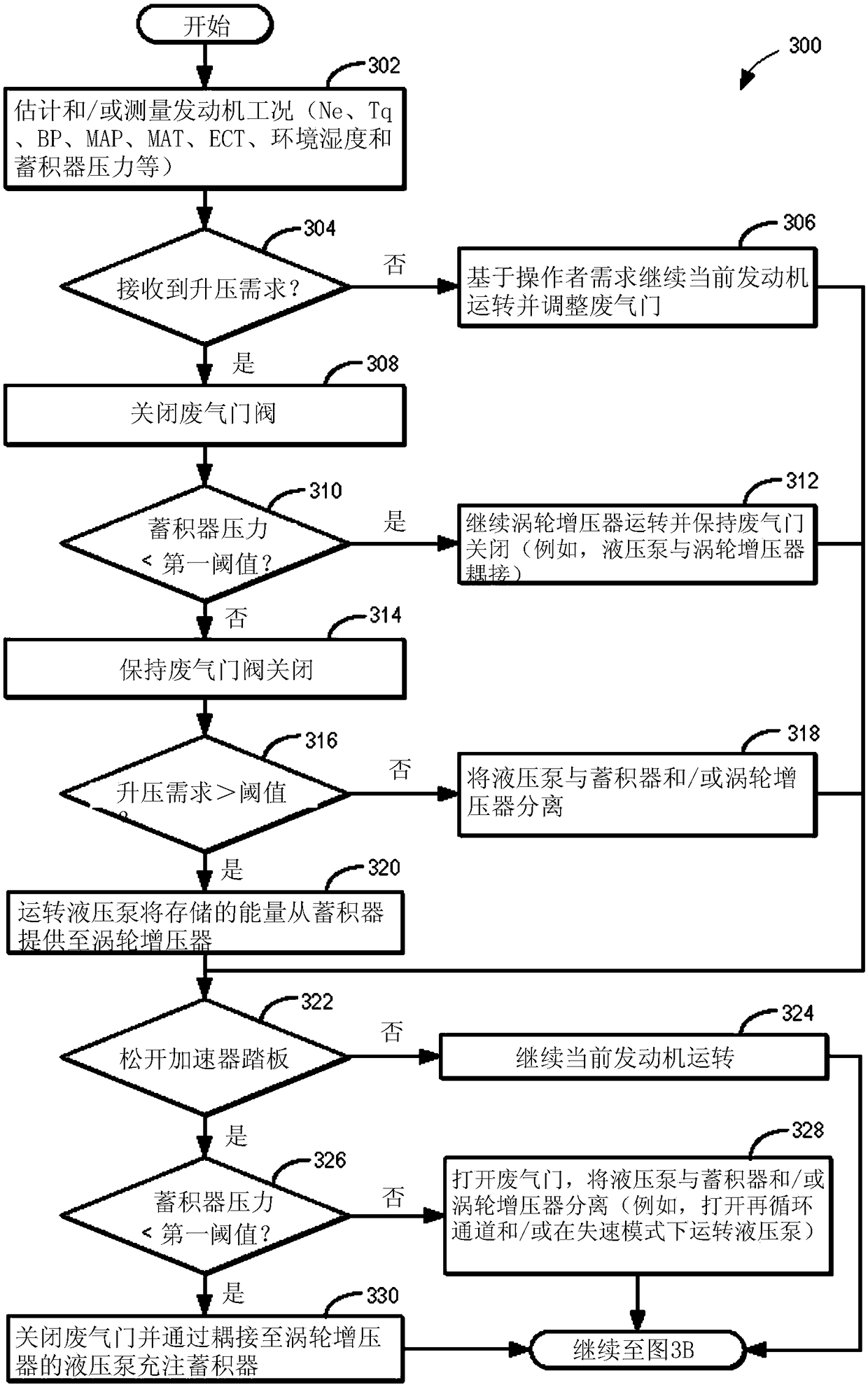

[0013] The following description relates to systems and methods for a hydraulic braking system that allows use of stop-start technology on hydraulic hybrid vehicles. An example of such a system includes a turbocharged engine, where the turbocharger is coupled to a hydraulic pump and accumulator, such as figure 1 shown. Where the accumulator may also be coupled to the vehicle's hydraulic braking system, and the hydraulic braking system may be configured to operate using hydraulic brake pressure from a main engine source or from the hydraulic accumulator, such as figure 2 shown. In one example, the engine may be a diesel (eg, compression ignition) engine, where the primary engine source may only supply hydraulic pressure to the hydraulic braking system when the engine is started and running. During engine operation, the controller program (eg, Figure 3A-Figure 3B example program shown) controls the hydraulic turbocharger. The vehicle controller may be configured to execute...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com