Vehicle compound transmission shaft and preparation method thereof

A composite material and composite material tube technology, which is applied in the production field of automobile transmission shafts, can solve the problems of complex process, low service life and reliability, and achieves simple preparation process, high overall reliability, and high interlayer torsional strength. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] In order to enable those skilled in the art to better understand the technical solutions of the present invention, the present invention will be described in detail below with reference to the accompanying drawings and specific embodiments.

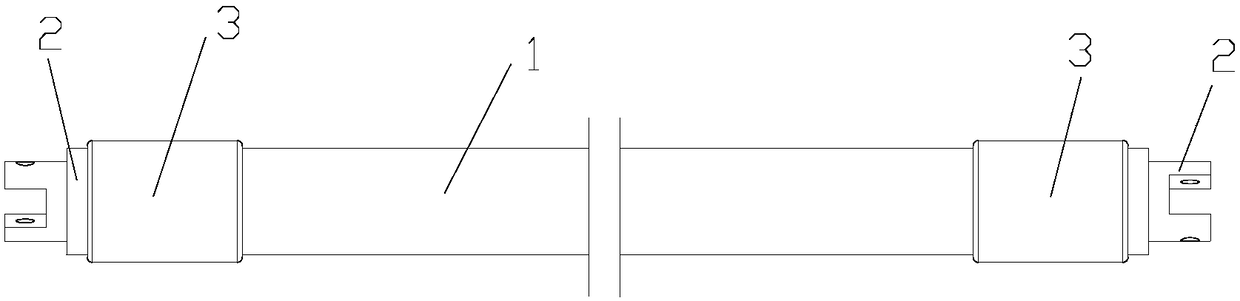

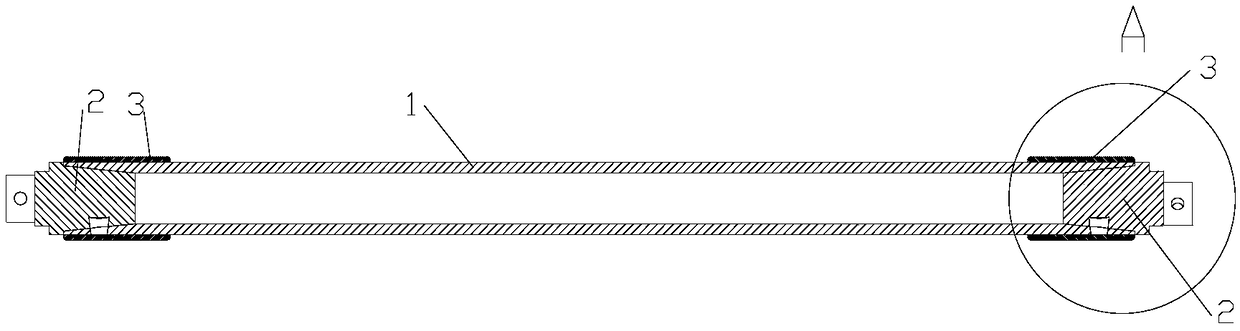

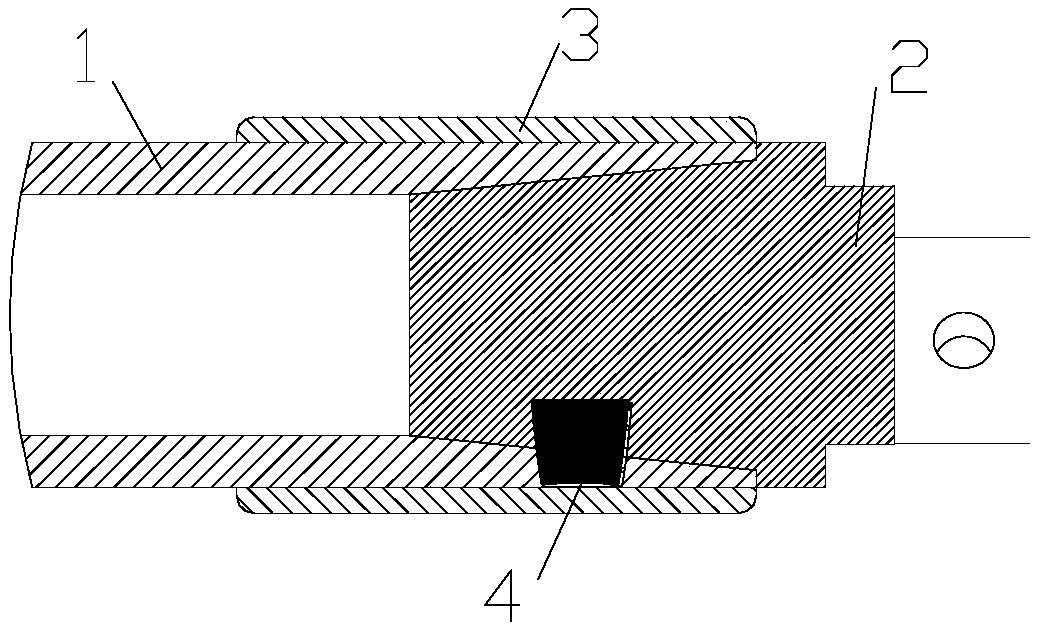

[0031] Such as Figure 1 to Figure 5 As shown, the embodiment of the present invention discloses a composite material drive shaft for vehicles, including a fiber reinforced composite tube (Fiber Reinforced Polymer / Plastic, FRP for short) 1, a metal connector 2 and a reinforcing sleeve 3, and fiber reinforced The inner and outer walls of the composite tube 1 are smooth and have uniform wall thickness to ensure good shaft dynamic balance performance during high-speed operation. A plurality of through holes 7 are uniformly distributed on the pipe wall at both ends of the fiber reinforced composite material pipe 1, and the metal connector 2 has the same outer diameter as the inner diameter of the end of the fiber reinforced composite mate...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com