Clothes dryer evaporator flushing device and method and clothes dryer

A flushing device and evaporator technology, applied in the field of clothes dryers, can solve problems such as the complexity of the internal structure and control procedures of the clothes dryer, the unfavorable overall stability of the clothes dryer, and the complicated program control, so as to facilitate market promotion and application, Simple and effective regular flushing, simplified control procedures and methods

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

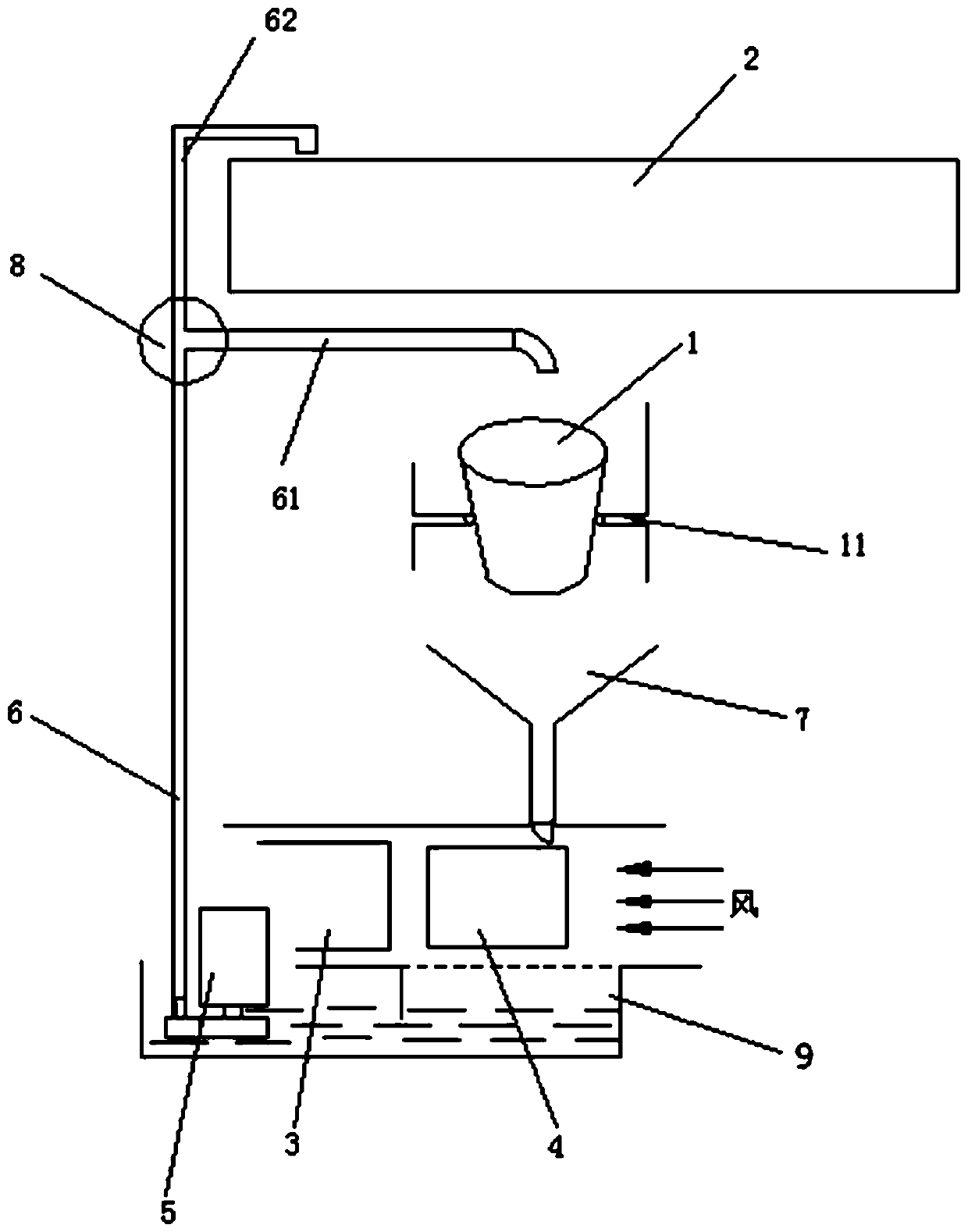

[0034] An evaporator flushing device for a clothes dryer, comprising an evaporator 4, a water storage box 2 and a condensed water pan 9 for receiving condensed water, an eccentric device for containing water is provided between the water storage box 2 and the evaporator 4, the The center of gravity of the eccentric device changes with the amount of water contained, so that the eccentric device can be turned over and the contained water can be poured into the evaporator 4 for flushing.

[0035] Specifically, the eccentric device in this implementation is set as an eccentric barrel 1:

[0036] An evaporator flushing device for a clothes dryer, comprising an evaporator 4, a water storage box 2 and a condensed water pan 9 for receiving condensed water, wherein an eccentric bucket 1 and an eccentric bucket are arranged between the water storage box 2 and the evaporator 4 1. There are support structures on both sides of the outer periphery that are symmetrical to each other. The sup...

Embodiment 2

[0059] The difference between this embodiment and Embodiment 1 is:

[0060] The first pipeline 61 and the second pipeline 62 are independently arranged respectively and equipped with a separate pump 5, and the pipe diameter of the first pipeline 61 and the second pipeline 62 or the setting of the pump 5 are adjusted to make the condensation of the first pipeline 61 and the second pipeline 62 The amount of water delivery is M:N-M, and the application of the present invention does not provide drawings.

[0061] An evaporator flushing device for a clothes dryer, comprising an evaporator 4, a water storage box 2 and a condensed water pan 9 for receiving condensed water, wherein an eccentric bucket 1 and an eccentric bucket are arranged between the water storage box 2 and the evaporator 4 1. There are support structures on both sides of the outer periphery that are symmetrical to each other. The support structure makes the eccentric barrel 1 turn over with the change of its own cen...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com