Automatic recognition device for position and posture of nuclear fuel rod

A nuclear fuel rod and automatic identification technology, which is applied to measurement devices, optical devices, instruments, etc., can solve the problems such as the technology directly related to the automatic assembly of nuclear fuel rod bundles that is not consulted, and achieves omitting the three-dimensional object reconstruction link, which is not easy. Image occlusion, the effect of improving image processing speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment 1

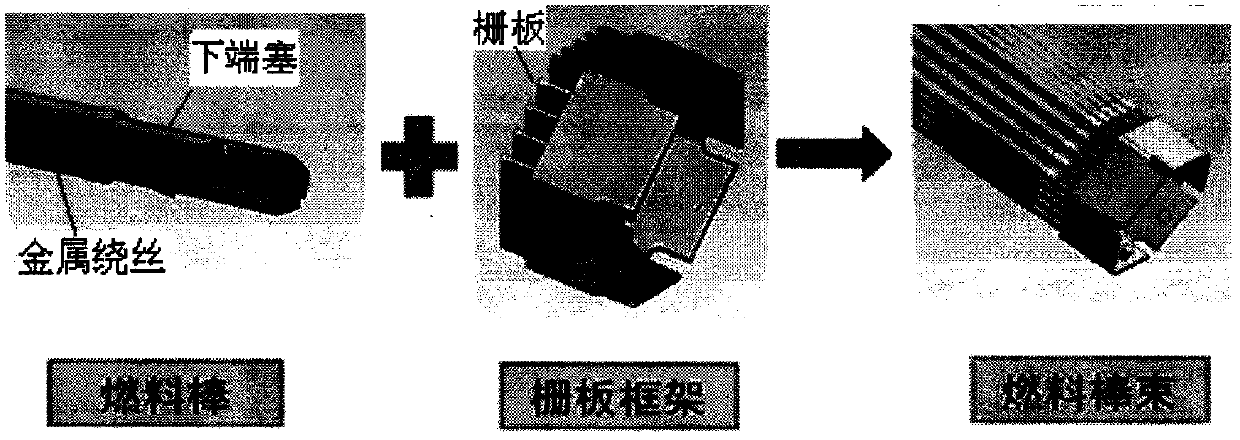

[0069] This embodiment is an embodiment of a device for automatically identifying the position and orientation of nuclear fuel rods.

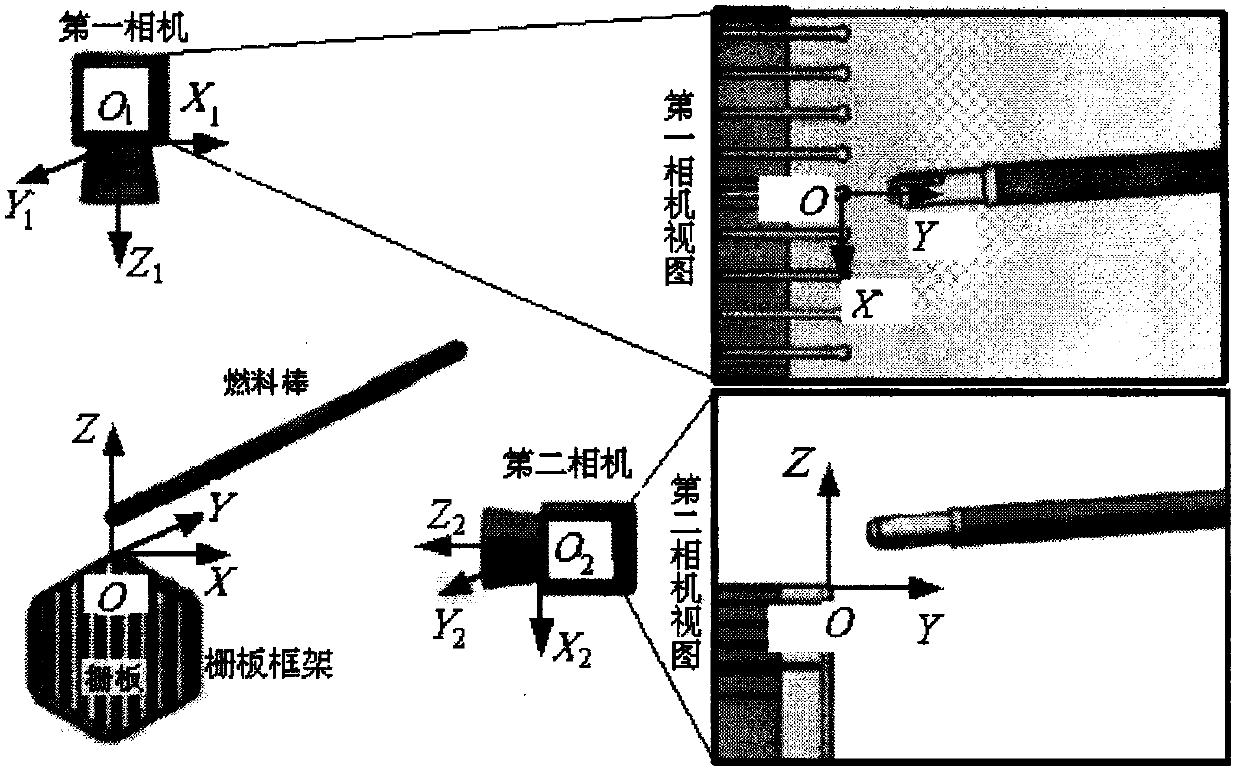

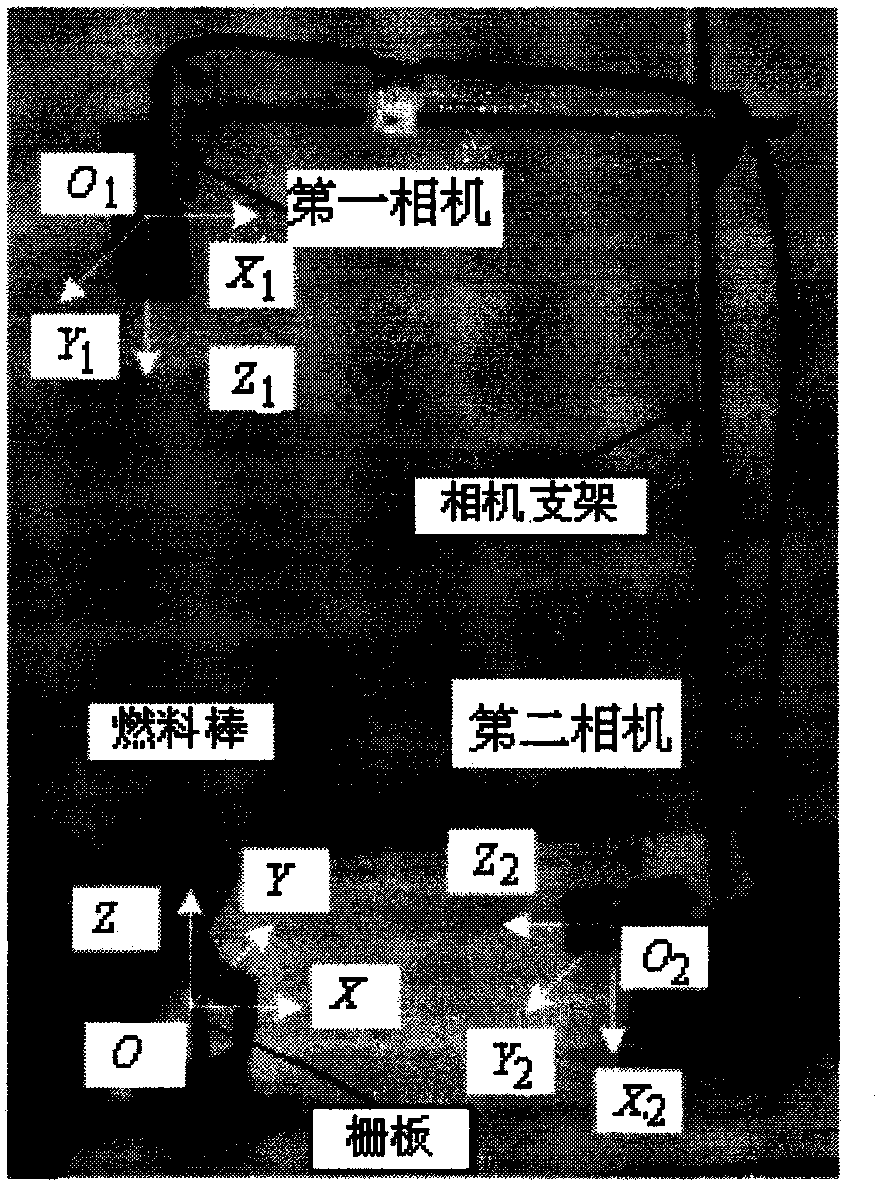

[0070] The nuclear fuel rod position and posture automatic recognition device of this embodiment, the schematic diagram and the physical diagram are respectively as follows figure 2 with image 3 shown. The nuclear fuel rod pose automatic identification device includes a first camera and a second camera arranged orthogonally,

[0071] The direction of the optical axis of the first camera is parallel to the Z axis, and the abscissa and ordinate of the image are respectively parallel to the X axis and the Y axis, which are used to detect the displacement information of the nuclear fuel rod lower end plug relative to the grid plate in the X axis direction and the Y axis direction , and the deflection angle α of the lower end plug opening slot rotating around the Y axis and the direction angle θ of the lower end plug axis in the XOY plane;

[0...

specific Embodiment 2

[0076] This embodiment is an embodiment of a device for automatically identifying the position and orientation of nuclear fuel rods.

[0077] The device for automatically recognizing the pose and posture of nuclear fuel rods in this embodiment, on the basis of the first embodiment, limits the minimum resolutions of the first camera and the second camera.

[0078] Define the diameter of the lower end plug of the nuclear fuel rod as D, the length of the opening slot as L, and the width of the opening slot as W 1 , the width of the grid frame is W, the height is H, the thickness of the grid is T, and the safety distance between the initial position of the lower end plug and the grid frame is D S , the minimum difference between the thickness of the grid plate and the width of the opening slot is Δ, that is, W 1 -T≥Δ, the image recognition accuracy is δ, take δ=Δ / 4;

[0079] The minimum resolution of the first camera is R A1 × R A2 , where R A1 ≥W / δ,R A2 ≥(2L+D S ) / δ;

[0...

specific Embodiment 3

[0090] This embodiment is an embodiment of a device for automatically identifying the position and orientation of nuclear fuel rods.

[0091] The nuclear fuel rod pose automatic recognition device of this embodiment, on the basis of specific embodiments 1 and 2, calibrates the internal and external parameters of the first camera and the second camera, including the following steps:

[0092] Step a, use the Zhang Zhengyou calibration method to calibrate the internal parameter f of the first camera x1 , f y1 , u 01 and v 01 ;

[0093] Step b. Use the Zhang Zhengyou calibration method to calibrate the internal parameter f of the second camera x2 , f y2 , u 02 and v 02 ;

[0094] The order of step a and step b can be replaced or carried out simultaneously;

[0095] Step c, photographing the same calibration board with the first camera and the second camera, respectively obtaining the first image of the calibration board and the second image of the calibration board;

[0...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com