Composite material sensor for detecting oil leakage of pipeline

A composite material and sensor technology, applied in the direction of detecting the appearance of fluid at the leak point, using liquid/vacuum degree for liquid tightness measurement, instruments, etc., can solve the problems of danger, low detection sensitivity, explosion, etc., and save manpower Material strength, rapid detection, high sensitivity and safety effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The present invention is explained in more detail below in conjunction with the examples and accompanying drawings, but the examples do not limit the present invention.

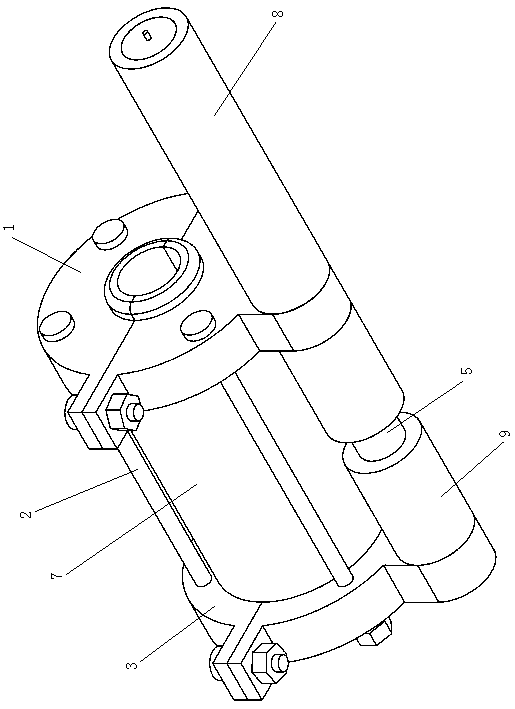

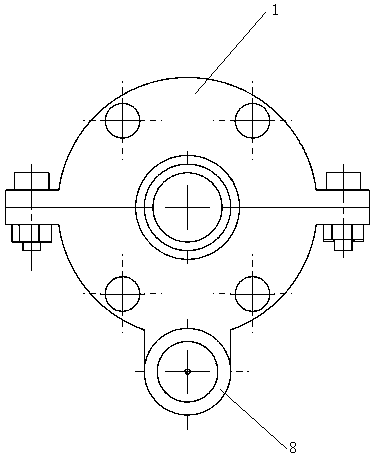

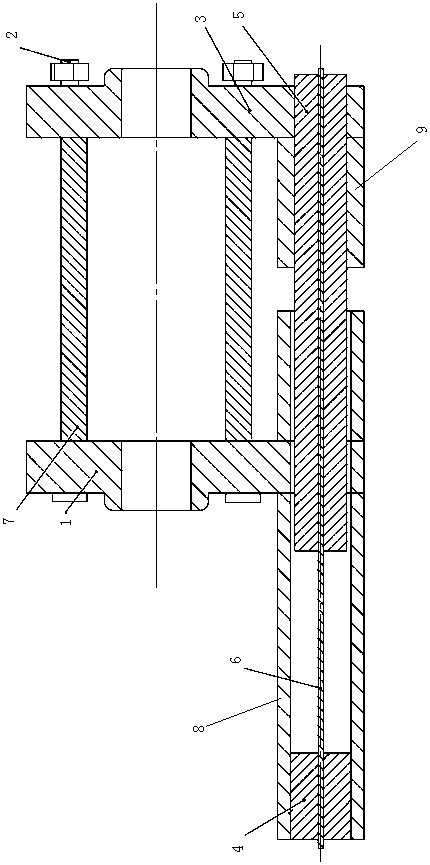

[0030] Such as Figure 1~3 As shown, the embodiment of the present invention provides a composite material sensor for pipeline oil leakage detection, including a sensitive element 7 that swells when encountering oil, a first fixed disk 1, a second fixed disk 3, a fiber grating 6, a first optical fiber The grating fixed armor 4, the second fiber grating fixed armor 5, the limit screw 2, the fiber grating demodulator, the sensitive element 7 is wrapped around the pipeline interface, and the first fixed disk 1 and the second fixed disk 3 are sleeved on the On the pipeline, and respectively in contact with the two ends of the sensitive element 7, the first fixed plate 1 is composed of two semi-circular rings, the center of which is perforated by the pipeline, one end of the two semi-circular rings is hinge...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com