Core displacement device capable of realizing synchronous evaluation of oil displacement effect

A technology of core displacement and oil displacement, which is applied in the direction of material inspection, soil material testing, etc., can solve the problems of prolonging the experimental development cycle, increasing economic costs, and being unable to simultaneously evaluate the pros and cons of various schemes, so as to shorten the evaluation cycle, The effect of stabilizing liquid inlet and reducing economic and space costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

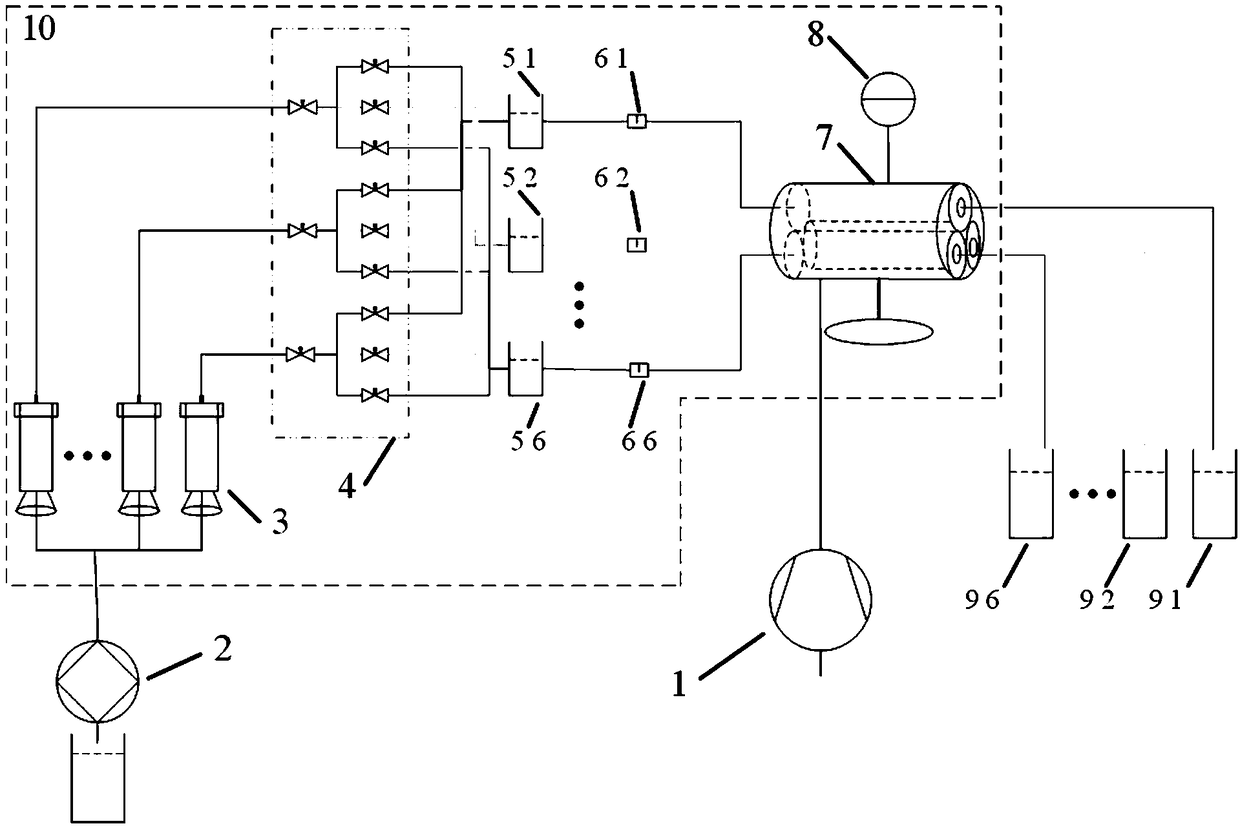

[0028] Such as figure 1 As shown, a core displacement device capable of synchronously evaluating the oil displacement effect includes: a water injection system, a core holder 7, a confining pressure pump 1, a pressure gauge 8, a constant temperature box 10 and a collection device,

[0029] The water injection system includes a non-pulse pump 2, six liquid storage tanks 3 arranged in the thermostat, a valve adjustment system 4, six buffer tanks and six liquid flowmeters, and the inlets of each liquid storage tank 3 are It is connected to the output end of the non-pulse pump 2, and the outlet of each liquid storage tank 3 is respectively connected to the corresponding buffer tank and the inner cavity input end of the core holder 7 through the valve adjustment system 4;

[0030] The core holder 7 is a cylindrical sealed structure placed in the constant temperature box, which includes three inner cavities for placing the core, the bottom of the core holder 7 is connected to the co...

Embodiment 2

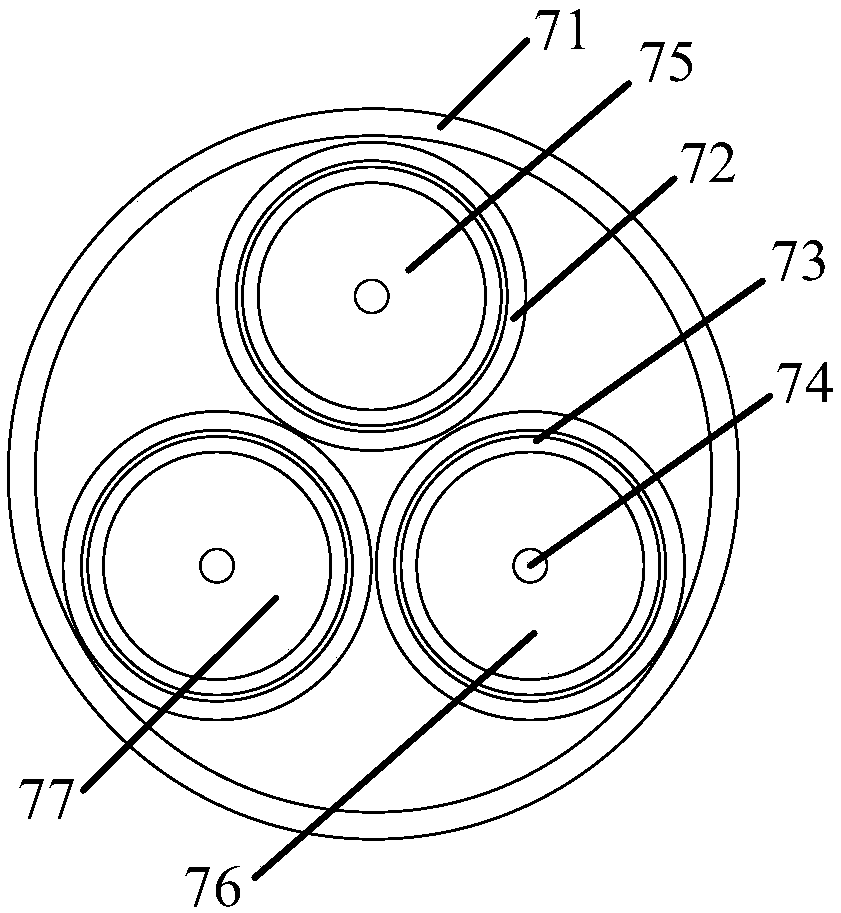

[0041] Such as image 3 As shown, the difference between this embodiment and Embodiment 1 is that the core holder 7 includes a cylindrical outer wall 71 with both ends sealed, and the outer wall 71 is provided with a rubber sleeve of the holder as a cavity wall 72 Form 4 inner cavities that do not interfere with each other, namely: cavity No. 1 75, cavity No. 2 76, cavity No. The middle part is respectively provided with a liquid inlet port 74 and an outlet port. The first cavity 75 , the second cavity 76 , the third cavity 77 and the fourth cavity 78 are uniformly arranged in a circular shape in the cylindrical outer wall 71 .

[0042] In this embodiment, the synchronous evaluation and oil displacement effect detection of four rock cores can be realized at the same time. In order to facilitate the installation of rock cores, the two sealing ends of the outer wall 71 are provided with four threaded holes and threaded plugs whose diameters match the inner cavity. The center o...

Embodiment 3

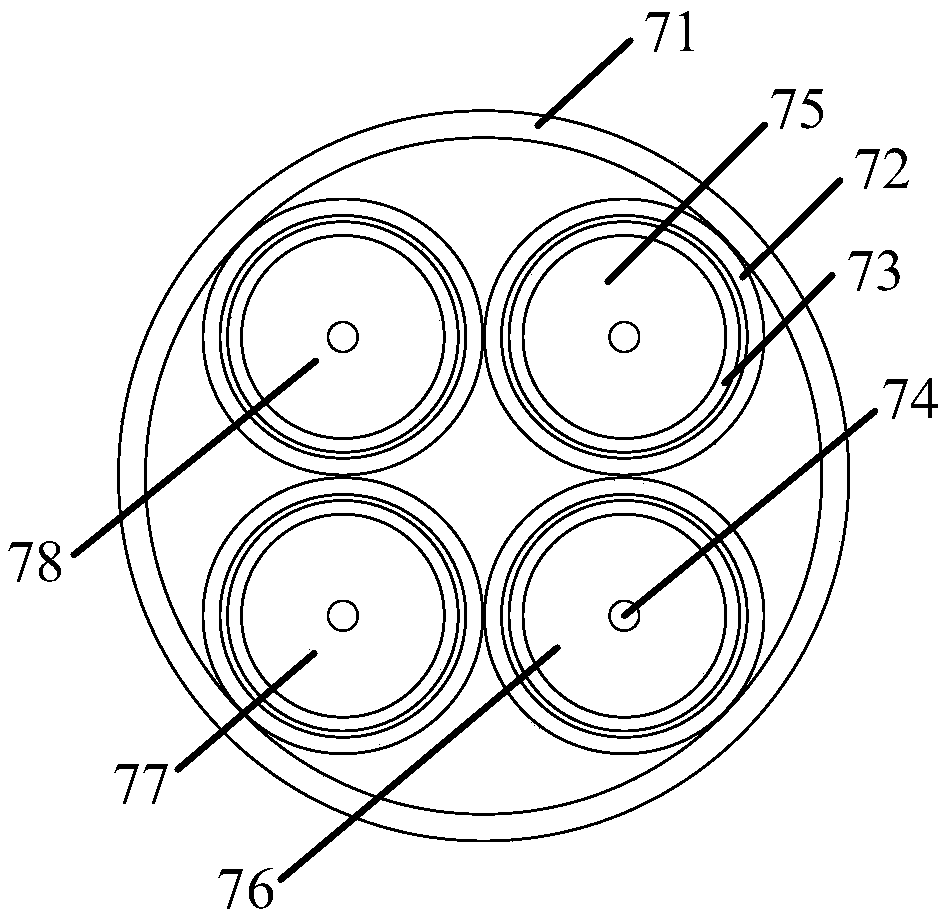

[0044] Such as Figure 4As shown, the difference between this embodiment and Embodiment 1 is that the core holder 7 includes a cylindrical outer wall 71 with both ends sealed, and the outer wall 71 is provided with a rubber sleeve of the holder as a cavity wall 72 Form 5 inner cavities that do not interfere with each other, namely: No. 1 cavity 75, No. 2 cavity 76, No. 3 cavity 77, No. 4 cavity 78, and No. 5 cavity 79, and plugs 73 are provided at both ends of the rubber sleeves of each holder , The middle parts of the two plugs are respectively provided with a liquid inlet port 74 and an outlet port. The first cavity 75 , the second cavity 76 , the third cavity 77 , the fourth cavity 78 and the fifth cavity 79 are uniformly arranged in a circular shape in the cylindrical outer wall 71 .

[0045] In this embodiment, the synchronous evaluation and oil displacement effect detection of five rock cores can be realized at the same time. In order to facilitate the installation of r...

PUM

| Property | Measurement | Unit |

|---|---|---|

| volume | aaaaa | aaaaa |

| volume | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com