PLC-based livestock waste disposal system and method

A waste treatment system and central control system technology, applied in the field of waste treatment, can solve problems such as incomplete elimination of germs, in the initial stage, environmental pollution, etc., and achieve good operating results, reduced intervention, and high automation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

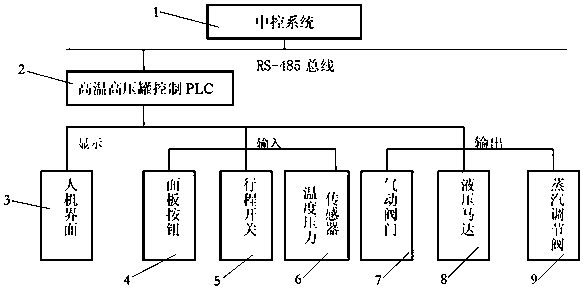

[0018] Such as figure 1 As shown, a PLC-based livestock waste disposal system is characterized in that it includes a central control system 1 and a high-temperature and high-pressure tank control PLC2 connected to the central control system 1. The high-temperature and high-pressure tank control PLC2 and a human-machine interface module 3, Panel button 4, travel switch 5, temperature and pressure sensor 6, pneumatic valve 7, hydraulic motor 8 and steam regulating valve 9 are connected.

[0019] In this embodiment, the central control system 1 is an industrial computer. The central control system uses Advantech industrial computer, and the control software is written by KingView. The main function is to control and monitor the production process of the entire factory. The staff can easily complete the entire production process through the central control system in the control center, and monitor the entire production process. Among them, the upper computer and the lower computer u...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com