Parametric modeling method and system for steel structure bridge model based on BIM technology

A parametric modeling and bridge model technology, applied in the direction of electrical digital data processing, special data processing applications, instruments, etc., can solve the problems of increasing the manufacturing cycle of detailed drawing conversion, reducing model quality, accuracy, and unfavorable rapid and accurate model establishment , to achieve the effect of shortening the manual drawing cycle, speeding up drawing, efficient design algorithm and interactive control mode

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

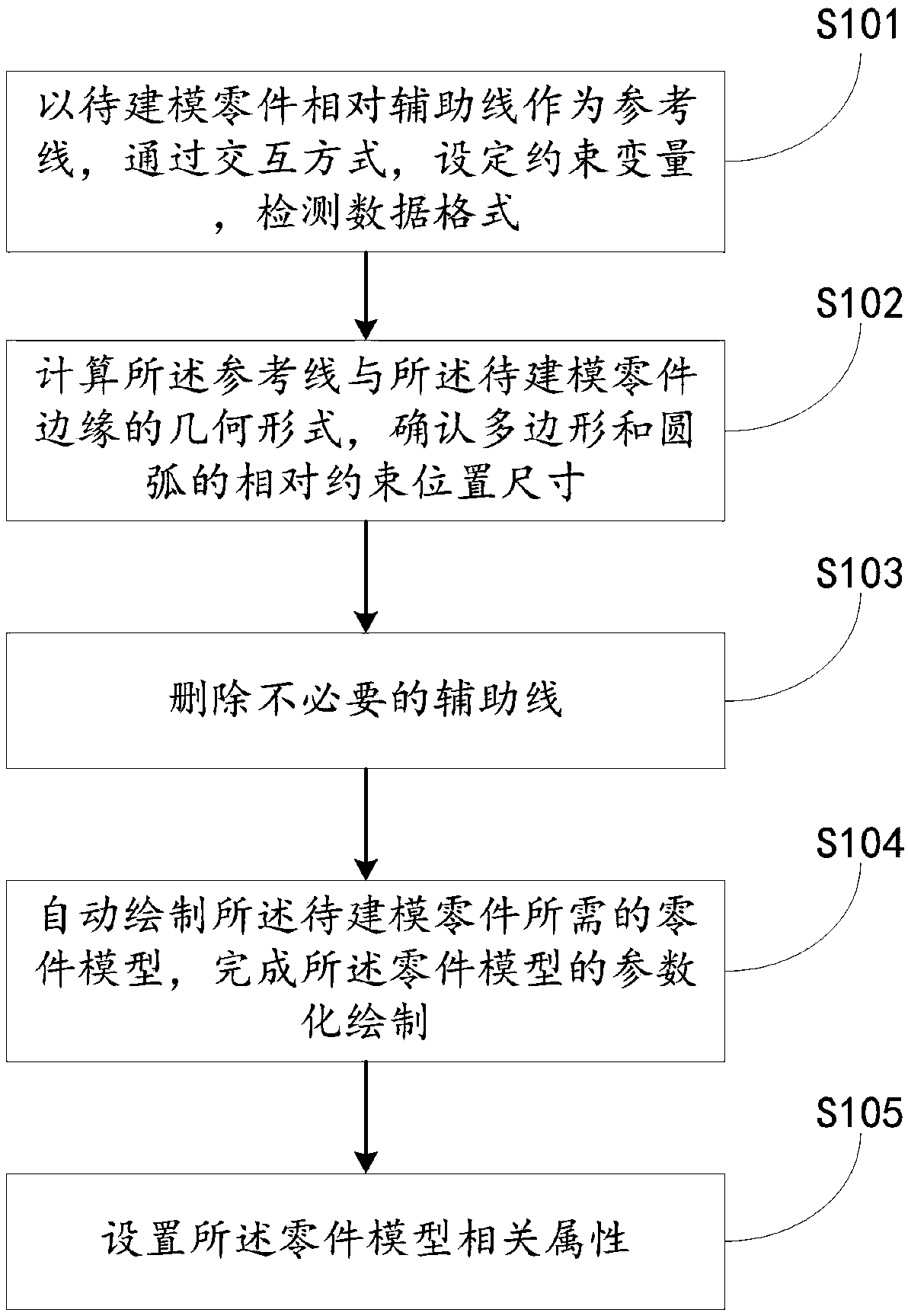

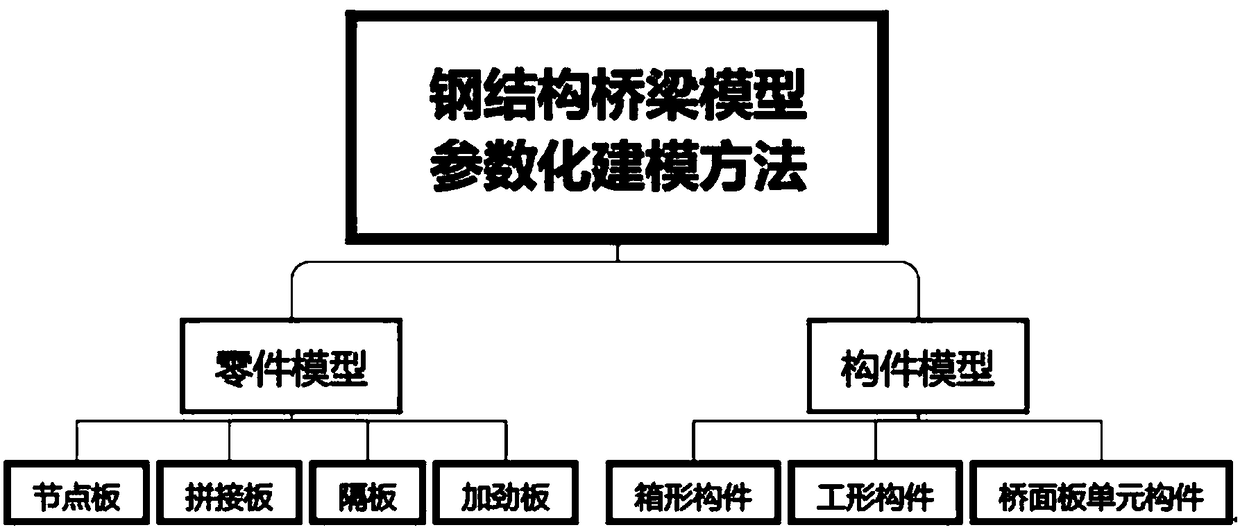

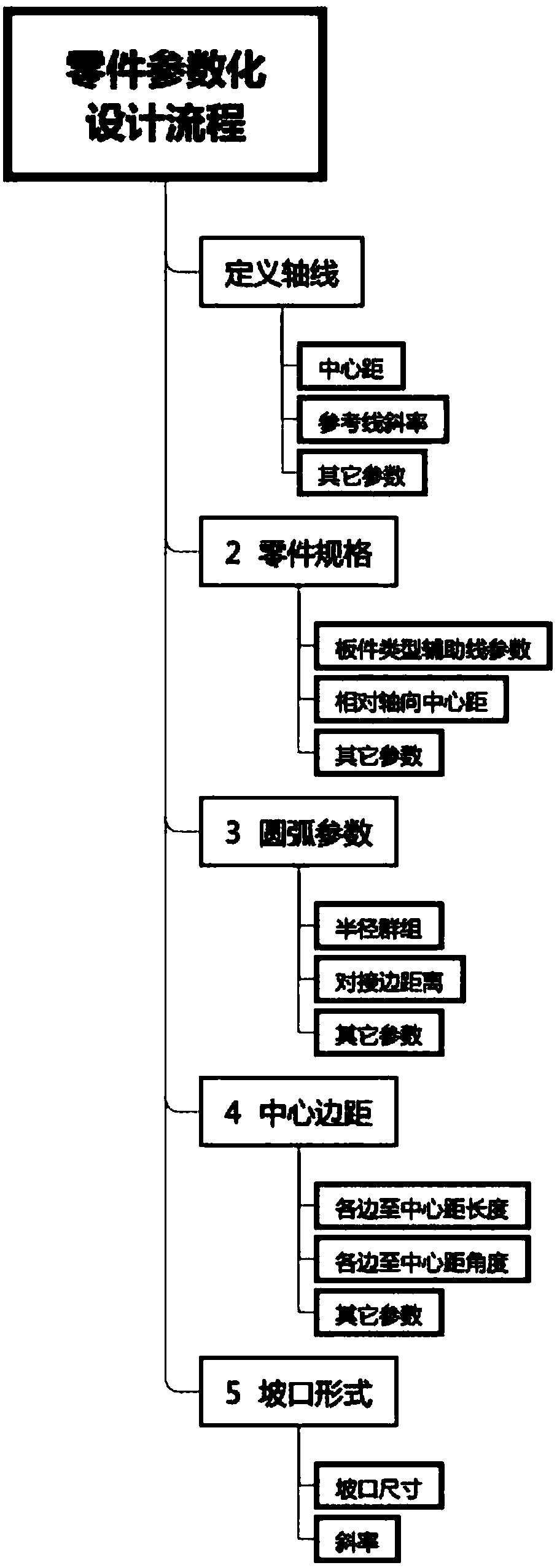

[0040] see figure 1 , figure 2 , image 3 , Figure 4 , Figure 5 , Figure 6 , Figure 7 , Figure 8 , Figure 9 , Figure 10 , a parametric modeling method for a steel structure bridge model based on BIM technology provided in Embodiment 1 of the present invention, such as figure 1 As shown, the method includes:

[0041] S101: Using the relative auxiliary line of the part to be modeled as a reference line, set constraint variables in an interactive manner, and detect the data format; specifically, the relative auxiliary line of the part to be modeled includes the center of the part, the center of the component, and the relative center of the unit component Wire.

[0042] S102: Calculate the geometric form of the reference line and the edge of the part to be modeled, and confirm the relative constraint position size of the polygon and the arc; specifically, the geometric form includes relative distance, length, angle, and arc radius. Confirm the relative constrain...

Embodiment 2

[0063] Corresponding to the parametric modeling method for a steel structure bridge model based on BIM technology provided in Embodiment 1 of the present invention, Embodiment 2 of the present invention also provides a parametric modeling system for a steel structure bridge model based on BIM technology; see Figure 11 , the system can include:

[0064] The reference line determination unit 201 is used to use the relative auxiliary line of the part to be modeled as a reference line, set constraint variables and detect data formats in an interactive manner;

[0065] A position size confirmation unit 202, configured to calculate the geometric form of the reference line and the edge of the part to be modeled, and confirm the relative constrained position size of the polygon and the arc;

[0066] A deletion unit 203, configured to delete unnecessary auxiliary lines;

[0067] Part model assembly unit 204, configured to automatically draw the part model required by the part to be m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com