Communication power compound cable for robot industry

A composite cable and robot technology, applied in the direction of power cables, power cables including optical transmission components, power cables with shielding layer/conductive layer, etc., can solve the problem of affecting the service life of cables, wasting resources, same frequency or close frequency Signal interference and other problems, to reduce the hidden dangers of fire house, the effect of solid structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0012] The technical solutions of the present invention will be described in detail below, but the protection scope of the present invention is not limited to the embodiments.

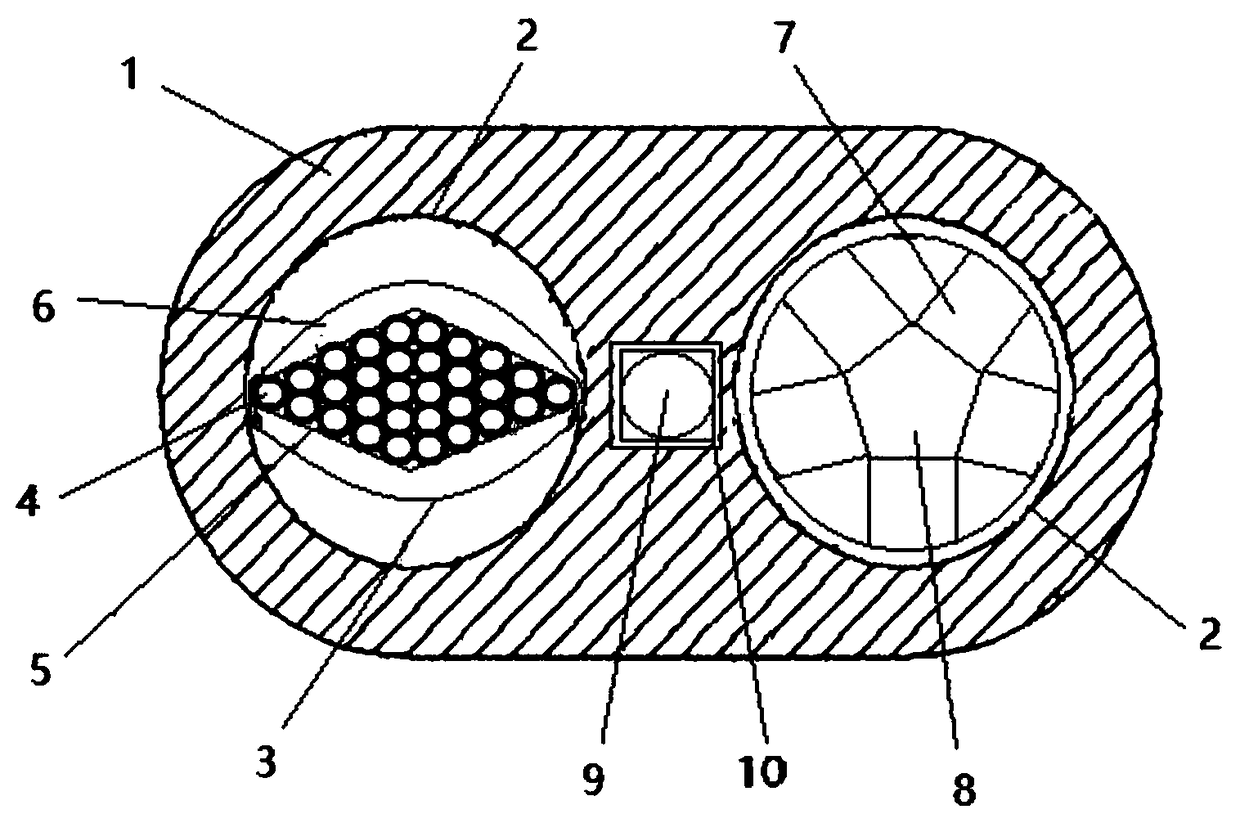

[0013] like figure 1 As shown, a communication power composite cable used in the robot industry of the present invention includes a composite cable sheath 1, and there are two first through holes 2 inside the composite cable sheath 1 for respectively accommodating the power cable core and the communication optical cable. The inner wall of the first through hole 2 is provided with an aluminum-coated layer. The communication optical cable is composed of several optical fibers 4. The cross-section of the several optical fibers 4 is quadrangular. The shielding layer 5 is filled with an epoxy resin adhesive layer 6, and the power cable core is composed of several copper cables 7, and the centers of the several copper cables 7 are sandwiched with a number of sequentially arranged cooling pipes 8, and the coo...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com