Trench gate super junction device and manufacturing method thereof

A technology of super junction devices and manufacturing methods, which is applied in the manufacture of trench gate super junction devices and the field of trench gate super junction devices, can solve the problems of cost increase and unfavorable device size reduction, and achieve cost saving and size reduction Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

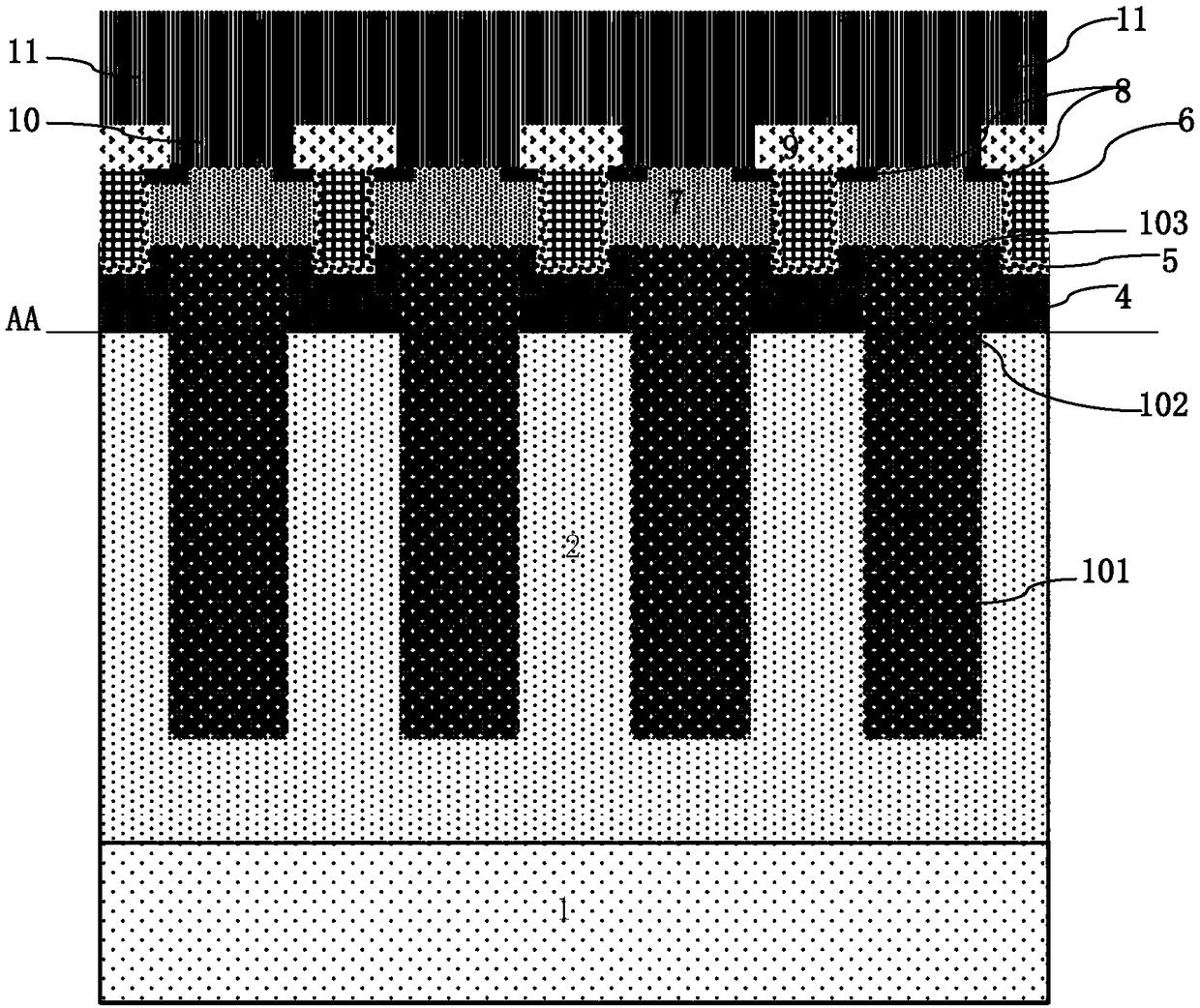

[0051] Such as figure 1As shown, it is a schematic structural diagram of a trench-gate super-junction device according to an embodiment of the present invention; the trench-gate super-junction device according to an embodiment of the present invention includes:

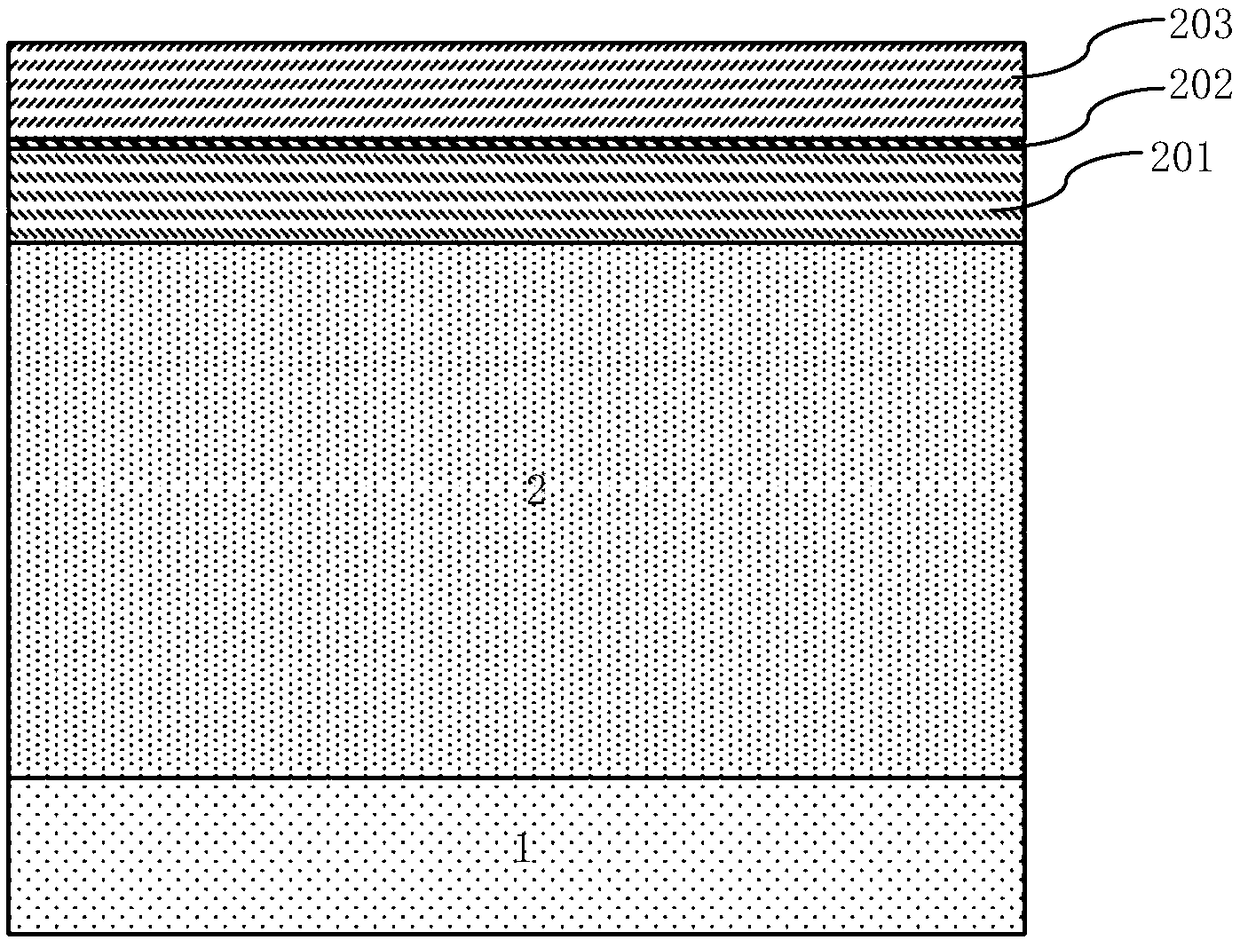

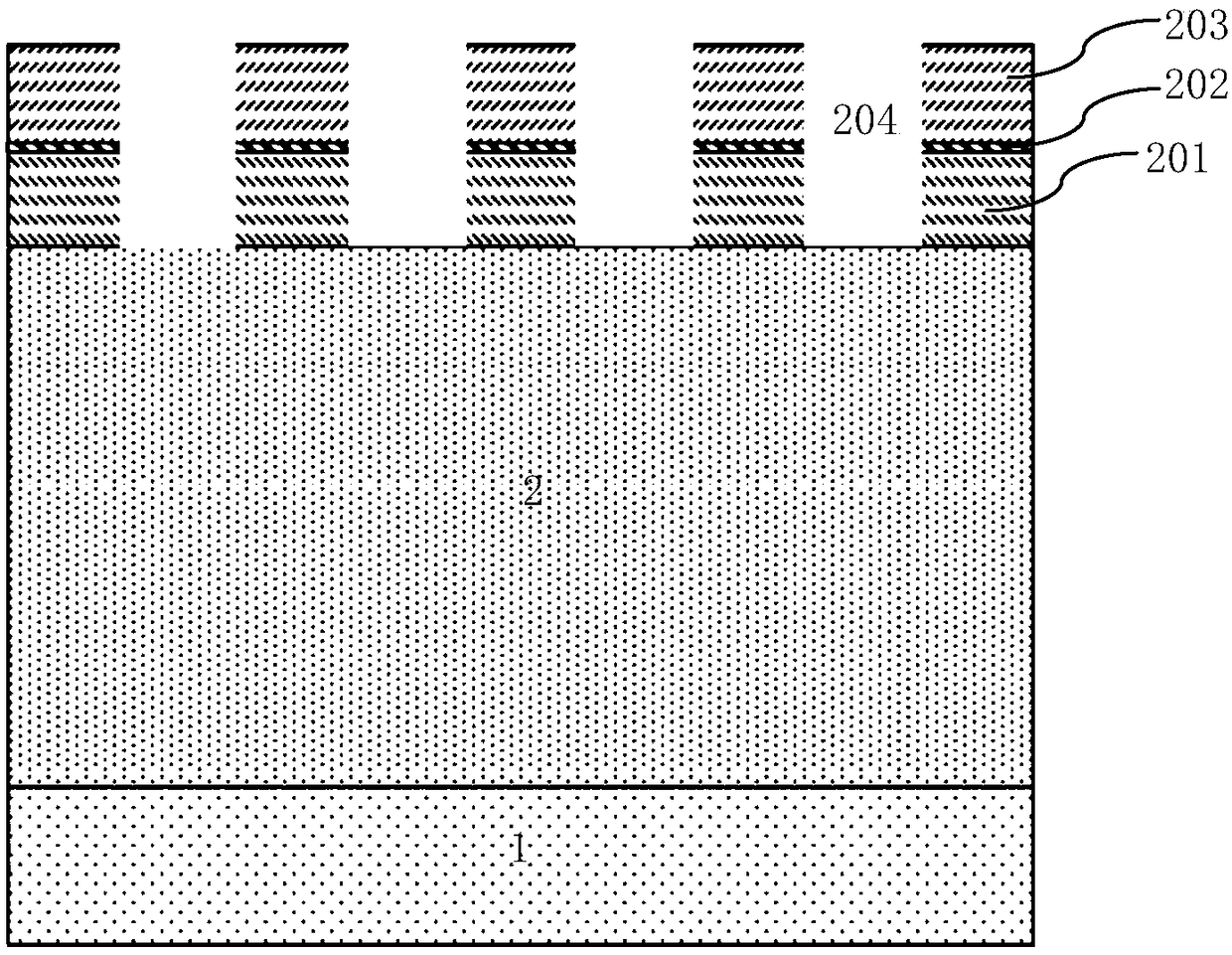

[0052] The super junction trench 101 is formed in the first N-type epitaxial layer 2; a hard mask layer is formed on the surface of the first N-type epitaxial layer 2, and the super junction trench 101 is formed by the hard mask The first opening 204 is defined by layer photolithography. For the first opening 204 please refer to Figure 2B shown.

[0053] The P-type epitaxial layer 3 is filled in the super junction trench 101 and the first opening 204 at the top to form a P-type thin layer 3 .

[0054] After the P-type thin layer 3 is formed, the hard mask layer is removed and the P-type protrusion structure of the P-type thin layer 3 is formed, and the P-type protrusion structure is filled in the first opening 204...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com