Special fertilizer spraying machine for oil sunflowers

A kind of fertilizer and mechanical technology, applied in the field of oil sunflower fertilizer spreading machinery, can solve the problems of time-consuming and laborious, easy soreness of the waist and arms, low efficiency of fertilizer spreading, etc., and achieve the effect of preventing blockage and improving the effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

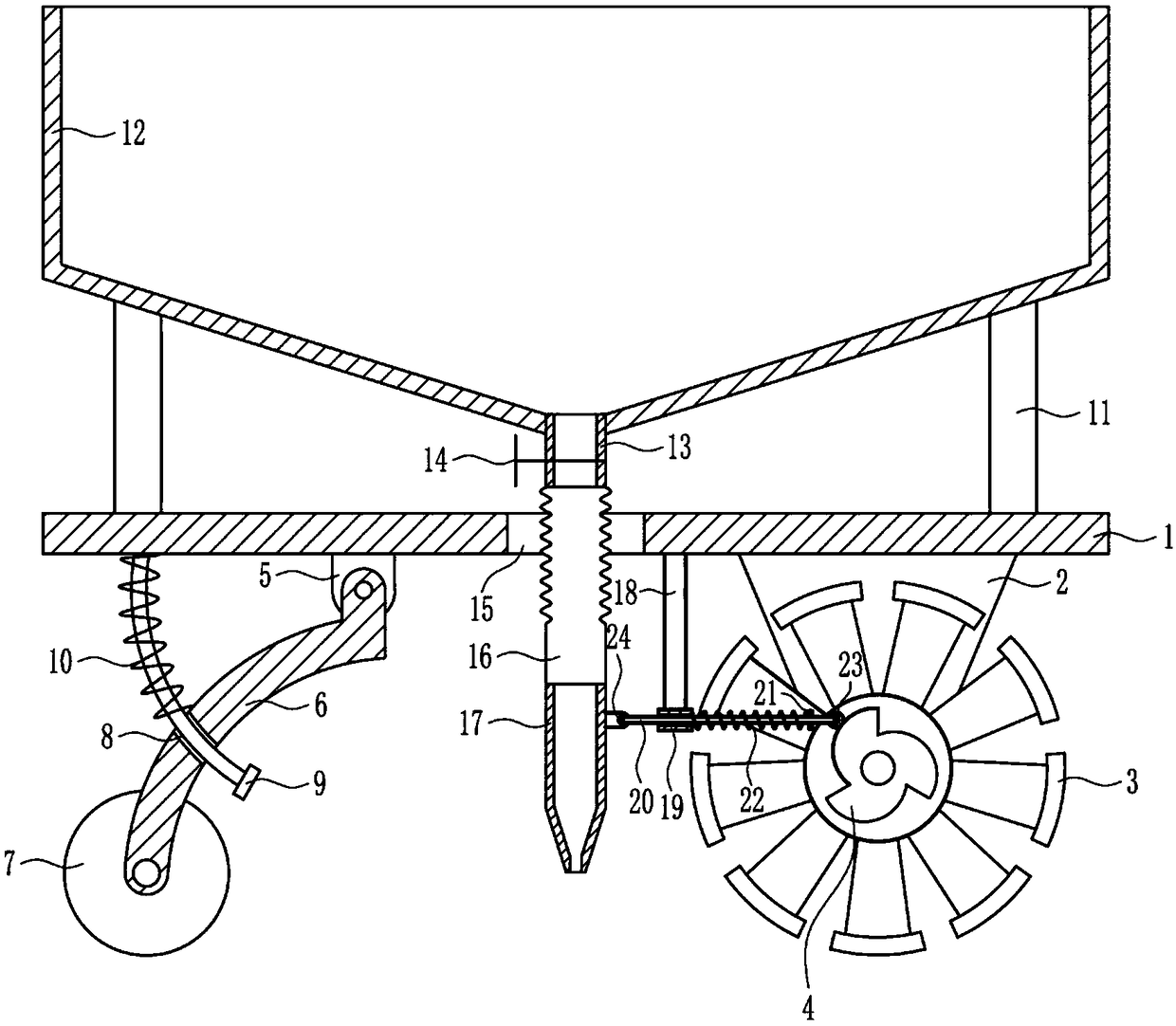

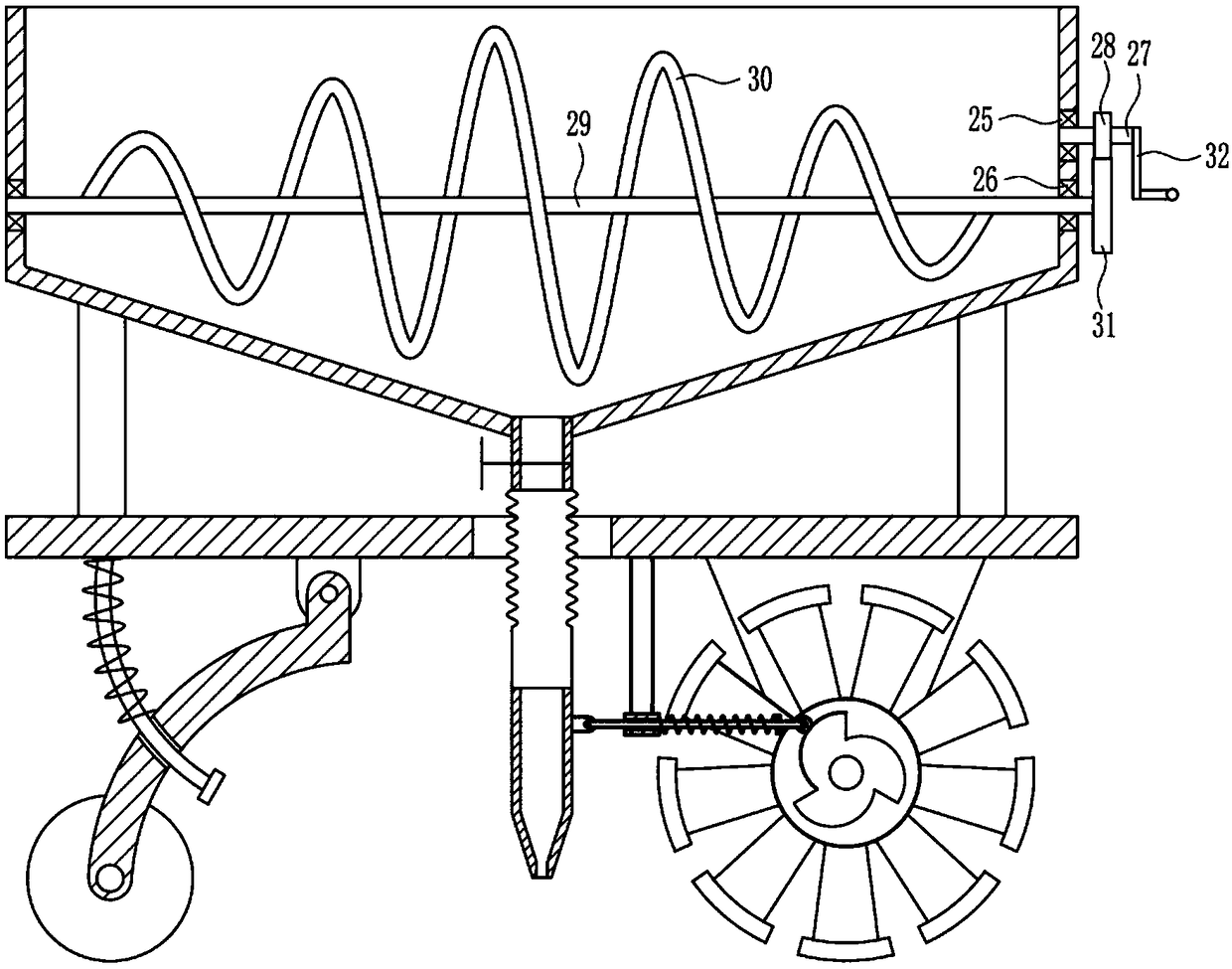

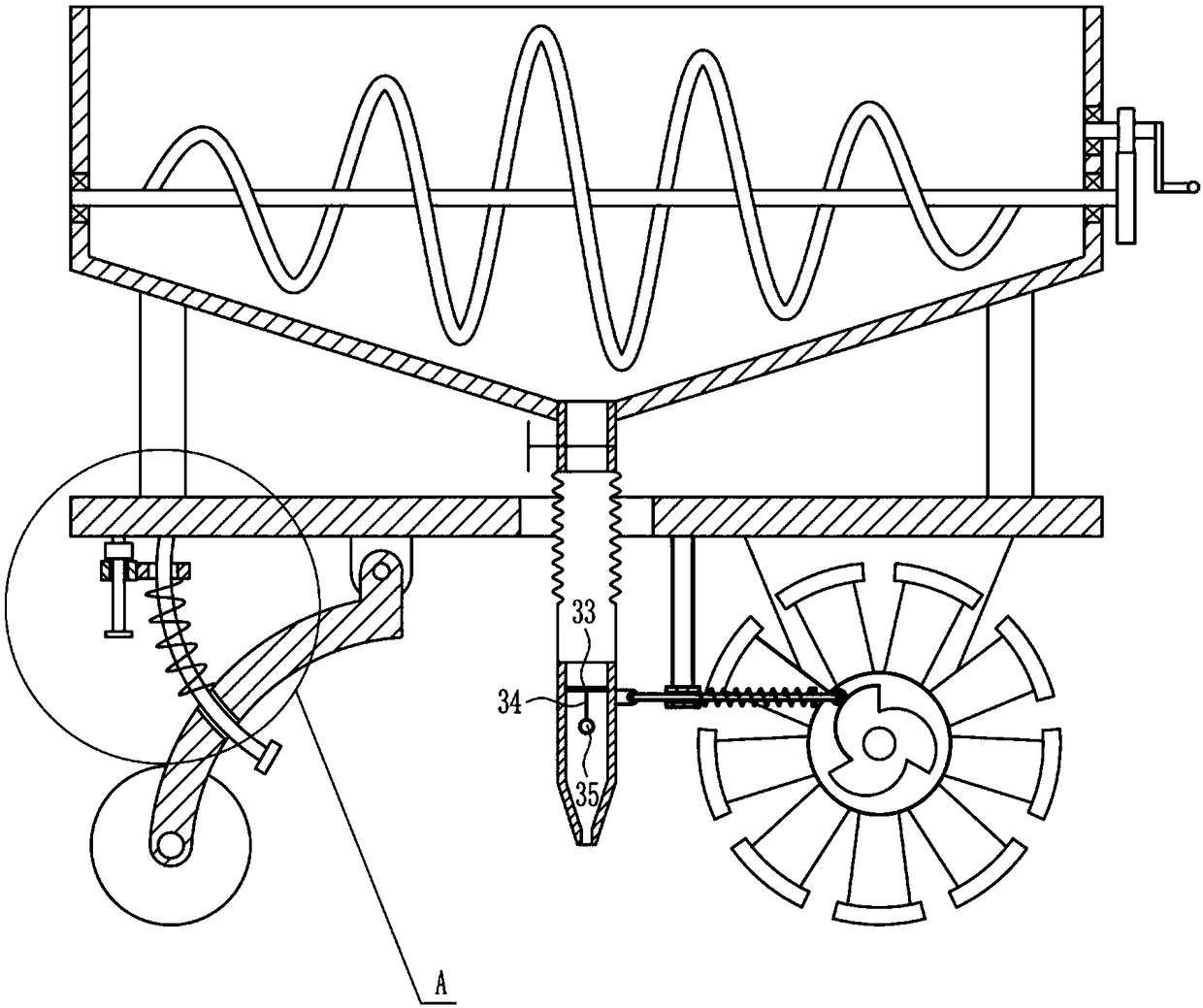

[0026] A machine dedicated to spreading fertilizers for oil sunflowers, such as Figure 1-6As shown, it includes support plate 1, mounting seat 2, first roller 3, polygonal cam 4, connecting seat 5, connecting rod 6, second roller 7, supporting rod 9, first spring 10, supporting rod 11, storage Box 12, first discharge pipe 13, valve 14, hose 16, second discharge pipe 17, vertical rod 18, first guide sleeve 19, guide rod 20, first connecting block 21, second spring 22, contact The wheel 23 and the second connection block 24, the bottom right side of the support plate 1 is connected with the mounting seat 2, the front side of the mounting seat 2 is connected with the first roller 3 in a rotating manner, and the front side of the first roller 3 is connected with a multi-sided cam 4, The left side of the bottom of the support plate 1 is connected with a connecting seat 5, the front side of the connecting seat 5 is rotatably connected with a connecting rod 6, the bottom of the conn...

Embodiment 2

[0028] A machine dedicated to spreading fertilizers for oil sunflowers, such as Figure 1-6 As shown, it includes support plate 1, mounting seat 2, first roller 3, polygonal cam 4, connecting seat 5, connecting rod 6, second roller 7, supporting rod 9, first spring 10, supporting rod 11, storage Box 12, first discharge pipe 13, valve 14, hose 16, second discharge pipe 17, vertical rod 18, first guide sleeve 19, guide rod 20, first connecting block 21, second spring 22, contact The wheel 23 and the second connection block 24, the bottom right side of the support plate 1 is connected with the mounting seat 2, the front side of the mounting seat 2 is connected with the first roller 3 in a rotating manner, and the front side of the first roller 3 is connected with a multi-sided cam 4, The left side of the bottom of the support plate 1 is connected with a connecting seat 5, the front side of the connecting seat 5 is rotatably connected with a connecting rod 6, the bottom of the con...

Embodiment 3

[0031] A machine dedicated to spreading fertilizers for oil sunflowers, such as Figure 1-6 As shown, it includes support plate 1, mounting seat 2, first roller 3, polygonal cam 4, connecting seat 5, connecting rod 6, second roller 7, supporting rod 9, first spring 10, supporting rod 11, storage Box 12, first discharge pipe 13, valve 14, hose 16, second discharge pipe 17, vertical rod 18, first guide sleeve 19, guide rod 20, first connecting block 21, second spring 22, contact The wheel 23 and the second connection block 24, the bottom right side of the support plate 1 is connected with the mounting seat 2, the front side of the mounting seat 2 is connected with the first roller 3 in a rotating manner, and the front side of the first roller 3 is connected with a multi-sided cam 4, The left side of the bottom of the support plate 1 is connected with a connecting seat 5, the front side of the connecting seat 5 is rotatably connected with a connecting rod 6, the bottom of the con...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com