Preparation method of lily plant body composite tea powder

A technology of compounding tea and lily, applied in the direction of tea substitutes and other directions, can solve the problems of improper mixing ratio, poor nutrient extraction rate of lily tea taste, weak health care function of lily tea, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

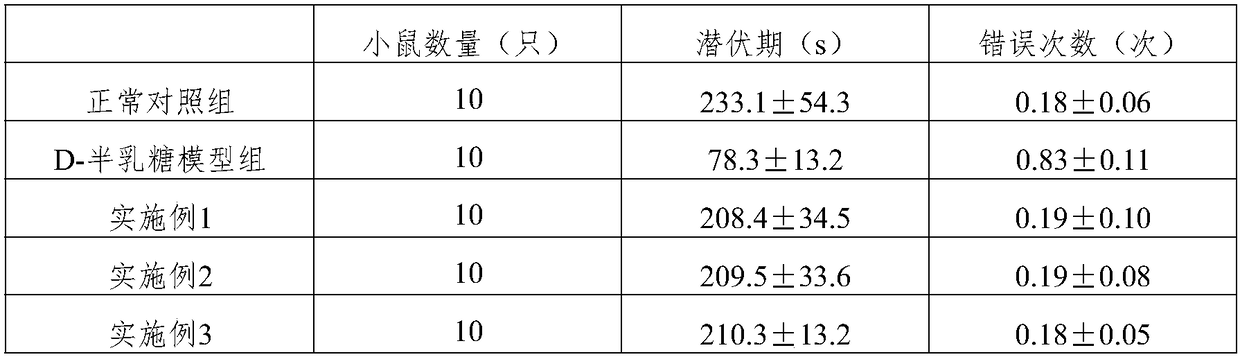

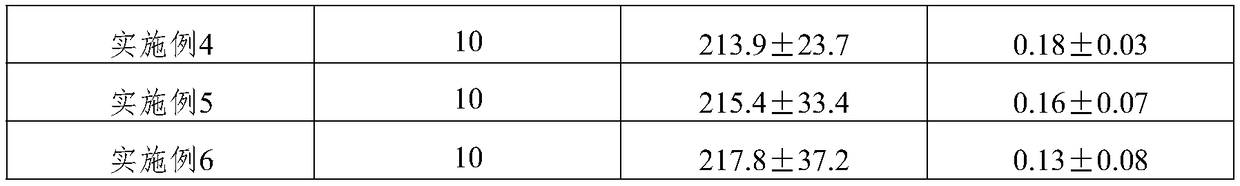

Examples

Embodiment 1

[0018] (1) picking fresh lily plant leaves and fresh lily buds, cleaning them, and mixing them according to a mass ratio of 1:1.3 to obtain a mixture;

[0019] (2) After the mixture is treated with steam at 300°C for 20 seconds, it is cooled to normal temperature, then placed in a grinder, and ground into a slurry;

[0020] (3) Add 0.3% of the mass of the slurry to the slurry by mixing cellulase and pectinase at a mass ratio of 1:0.3 to form a compound enzyme, stir evenly, and place it in an environment with a temperature of 30°C for 4 hours , to obtain the enzymatic solution;

[0021] (4) Spray-drying the enzymatic hydrolysis solution under normal temperature and normal pressure environment to obtain lily plant compound tea powder.

Embodiment 2

[0023] (1) Picking fresh lily plant leaves and fresh lily buds, and after cleaning them, mix according to the mass ratio of 1:2.7 to obtain the mixture;

[0024] (2) After the mixture is treated with 400°C steam for 30 seconds, it is cooled to normal temperature, then placed in a grinder, and ground into a slurry;

[0025] (3) Add 0.8% of the mass of the slurry to the slurry by mixing cellulase and pectinase at a mass ratio of 1:0.8 to form a compound enzyme, stir evenly, and place it in an environment with a temperature of 50°C for 8 hours , to obtain the enzymatic solution;

[0026] (4) Spray-drying the enzymatic hydrolysis solution under normal temperature and normal pressure environment to obtain lily plant compound tea powder.

Embodiment 3

[0028] (1) picking fresh lily plant leaves and fresh lily buds, cleaning them, and mixing them according to the mass ratio of 1:2 to obtain a mixture;

[0029] (2) After the mixture is treated with steam at 350°C for 25 seconds, it is cooled to normal temperature, then placed in a grinder, and ground into a slurry;

[0030] (3) Add 0.5% of the mass of the slurry to the slurry by mixing cellulase and pectinase at a mass ratio of 1:0.7 to form a compound enzyme, stir evenly, and place it in an environment with a temperature of 40°C for 6 hours , to obtain the enzymatic solution;

[0031] (4) Spray-dry the enzymatic hydrolysis solution in an environment with a vacuum degree of 0.02 MPa to obtain the compound tea powder of the lily plant body.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com