Waste gas purifying device

An exhaust gas purification device and electrostatic precipitator technology, which is applied in chemical instruments and methods, solid separation, electrostatic separation, etc., can solve the problems that indoor exhaust gas purification devices do not use electrocoagulation combining units, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

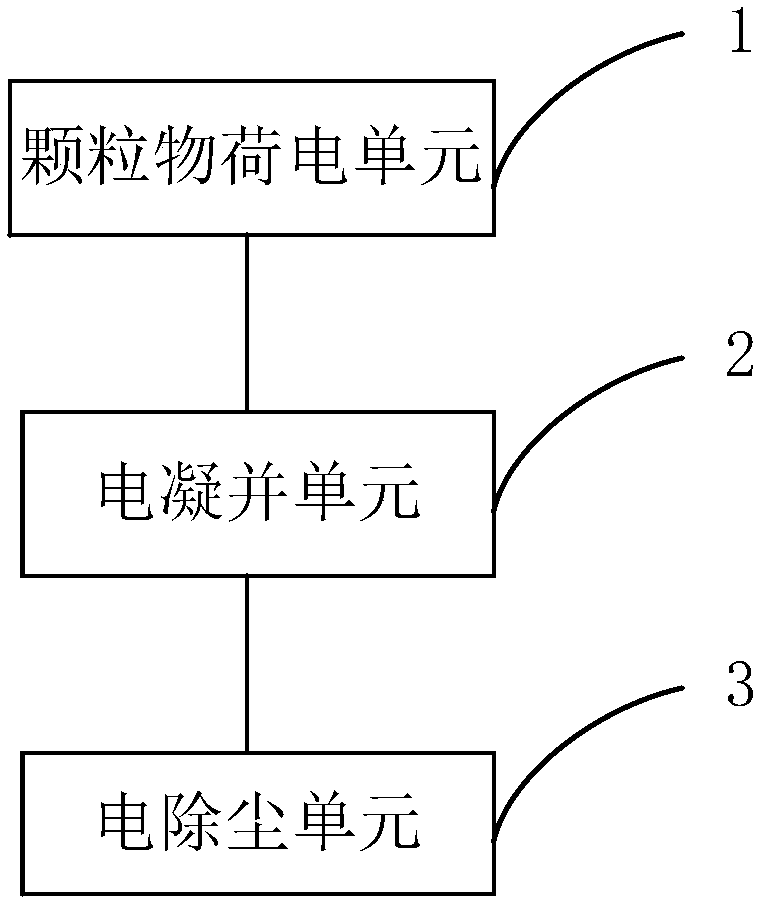

[0021] figure 1 is a schematic structural diagram of an exhaust gas purification device according to an embodiment of the present invention. Such as figure 1 As shown, the exhaust gas purification device of the present invention includes a particle charging unit 1 , an electrocoagulation unit 2 and an electrostatic precipitator unit 3 . The particle charging unit 1 is used to charge the particles when they flow through the high-voltage corona electric field between the electrodes; Particles are charged particles through the inertial collision between particles, particle diffusion, space charge force, heteropolar attraction between particles, image force between particles or between particles and the wall to make the fine particles condense; the electrostatic precipitator unit 3 is set in the electric Downstream of the coalescing unit 2, large particles are adsorbed to the electrodes by ionizing the gas using an electrostatic field. The indoor exhaust gas purification device...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com