Novel rolling type sand sieving machine

A rolling type, sand screening machine technology, applied in the direction of filter screen, solid separation, grille, etc., can solve the problems of poor practicability, difficulty in breaking up sand materials quickly, and affecting the working efficiency of sand screening, so as to achieve strong practicability , Improve sand screening efficiency, simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The technical solutions in the embodiments of the present invention will be clearly and completely described below in conjunction with the accompanying drawings in the embodiments of the present invention. Obviously, the described embodiments are only some of the embodiments of the present invention, not all of them.

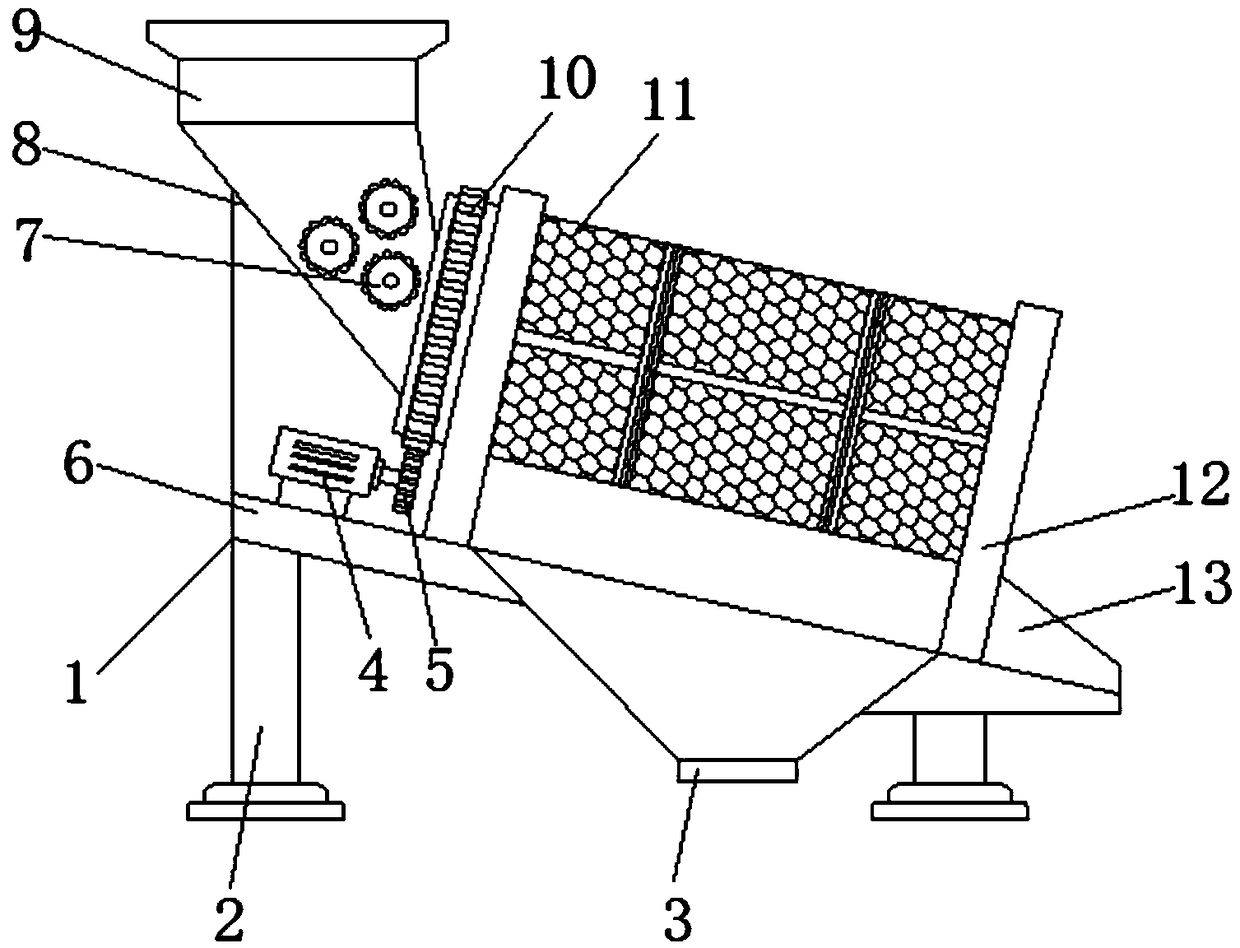

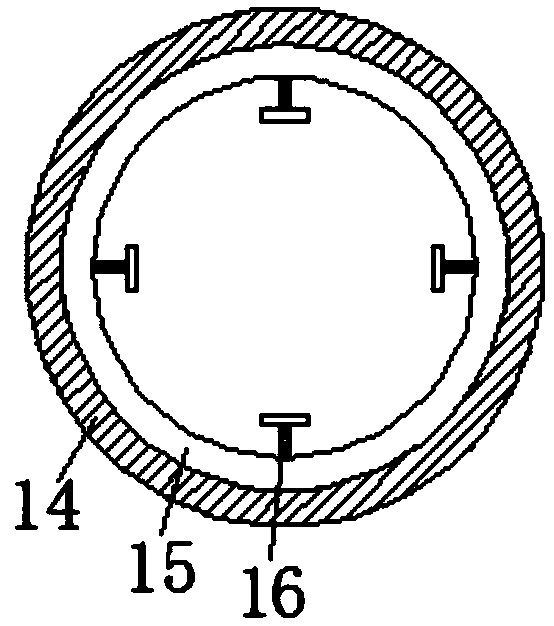

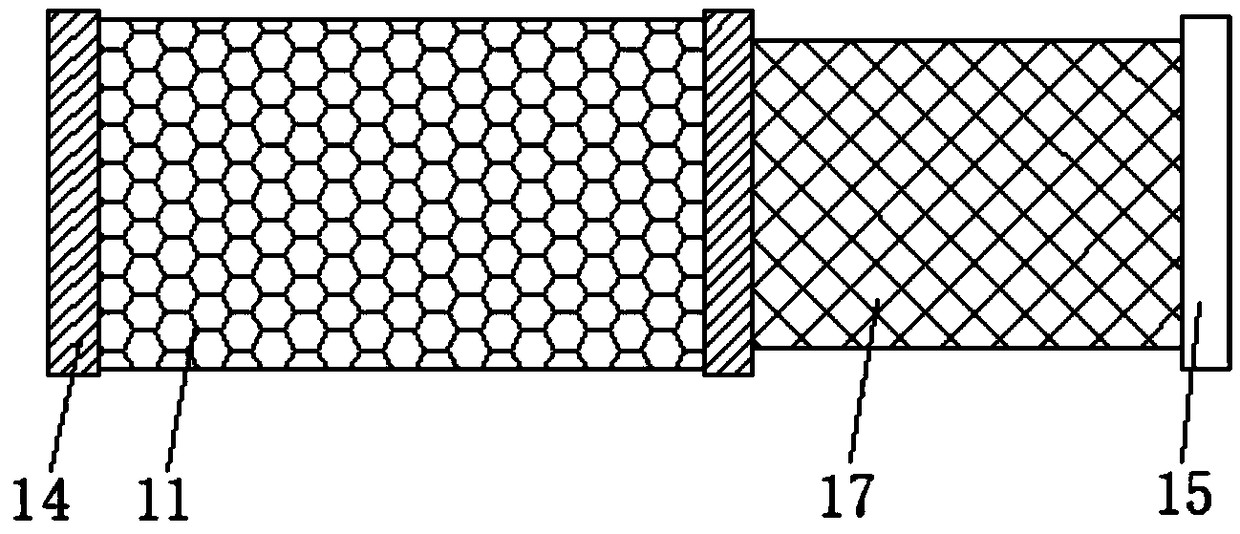

[0022] refer to Figure 1-3 , a new rolling type sand screening machine, comprising a sand rolling machine body 1, an outer sand rolling filter screen 11 and a coarse material outlet 13, a fixed platform 6 is arranged on the sand rolling machine body 1, and a vertical welding Two supporting frames 12, an outer sand rolling filter screen 11 is arranged to rotate between the two supporting frames 12, and an inner sand rolling filter screen 17 is set inside the outer sand rolling screen screen 11, and one end of the outer sand rolling screen screen 11 A ring gear 10 is sheathed on the outside, and the bottom of the ring gear 10 is connected to the drive moto...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com