Hot forging equipment having auxiliary mold loading and unloading function

A mold and hot forging technology, which is applied in the field of hot forging equipment with auxiliary mold loading and unloading, can solve the problems of upper mold falling and crushing, unfavorable safe production, mold scalding, etc., and achieve the effect of improving safety performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

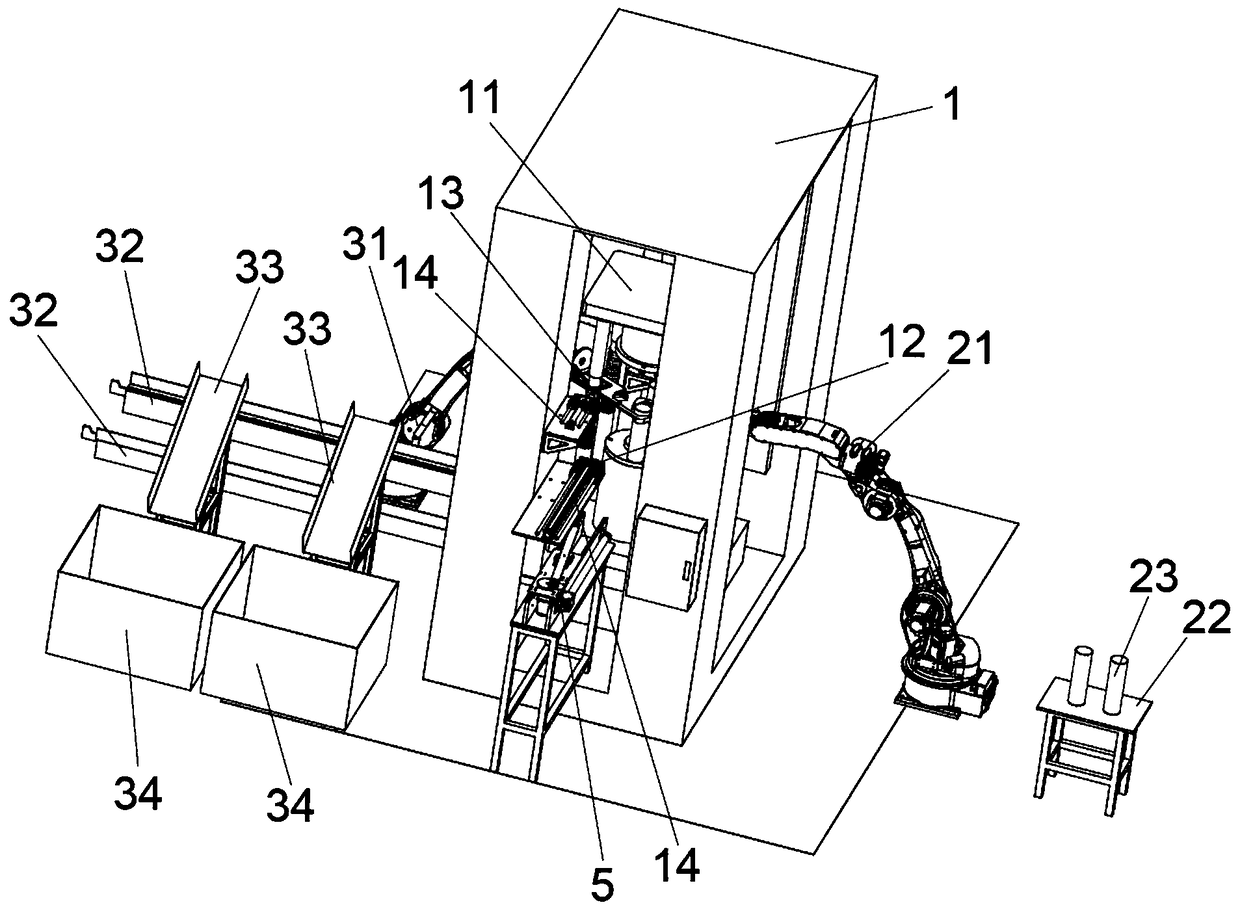

[0030] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments, so that those skilled in the art can better understand the present invention and implement it, but the examples given are not intended to limit the present invention.

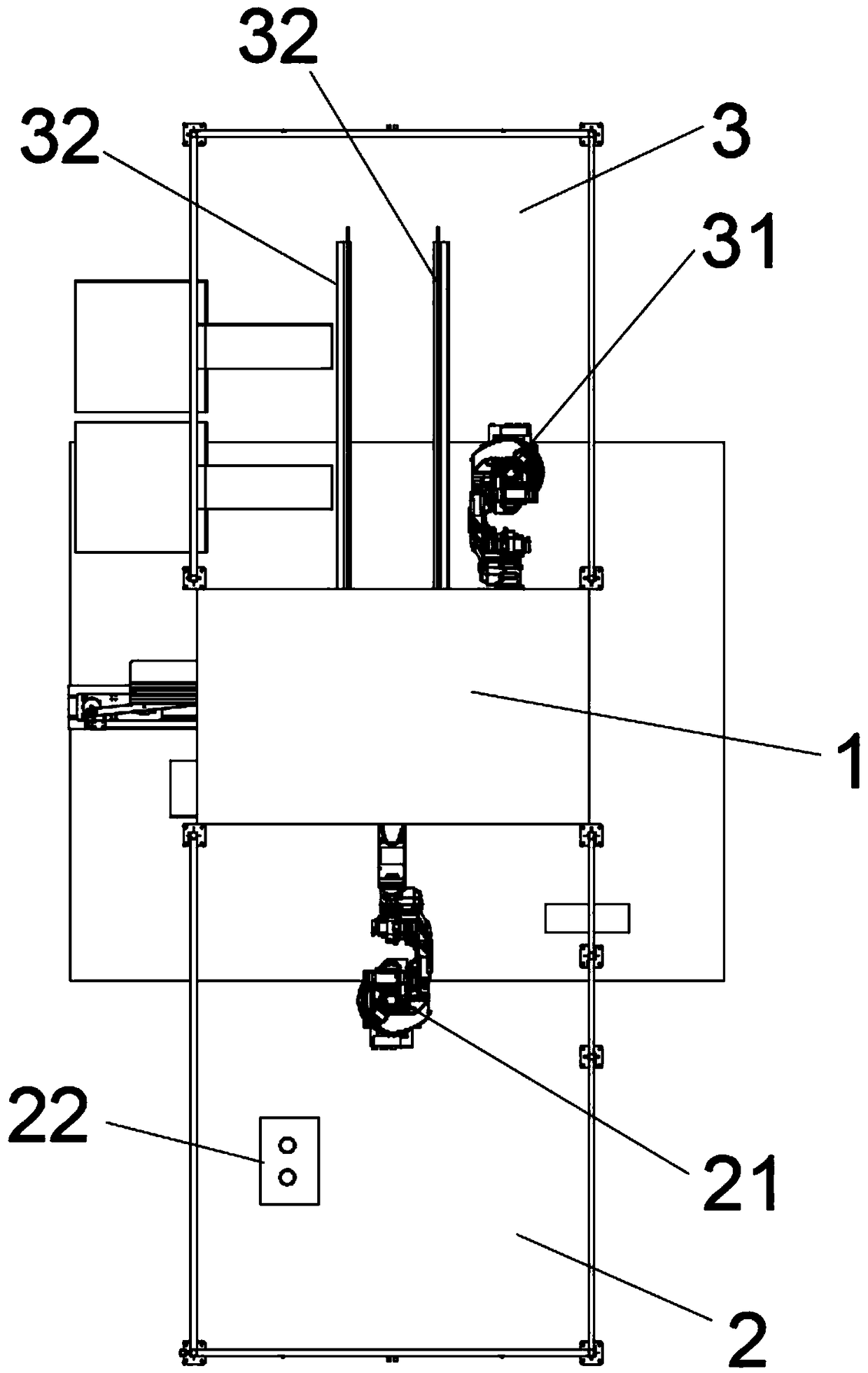

[0031] refer to Figure 1 to Figure 3 As shown, an embodiment of the hot forging equipment with auxiliary mold loading and unloading of the present invention includes a forging press body 1 and a feeding area 2 and a feeding area 3 arranged on both sides of the forging press body. The feeding area is used for Transfer the material to the inside of the forging press body for forging and pressing. After forging and pressing, the finished product is discharged from the blanking area, and a hot forging die 11 is installed in the forging press main body, and the finished product is formed by the die;

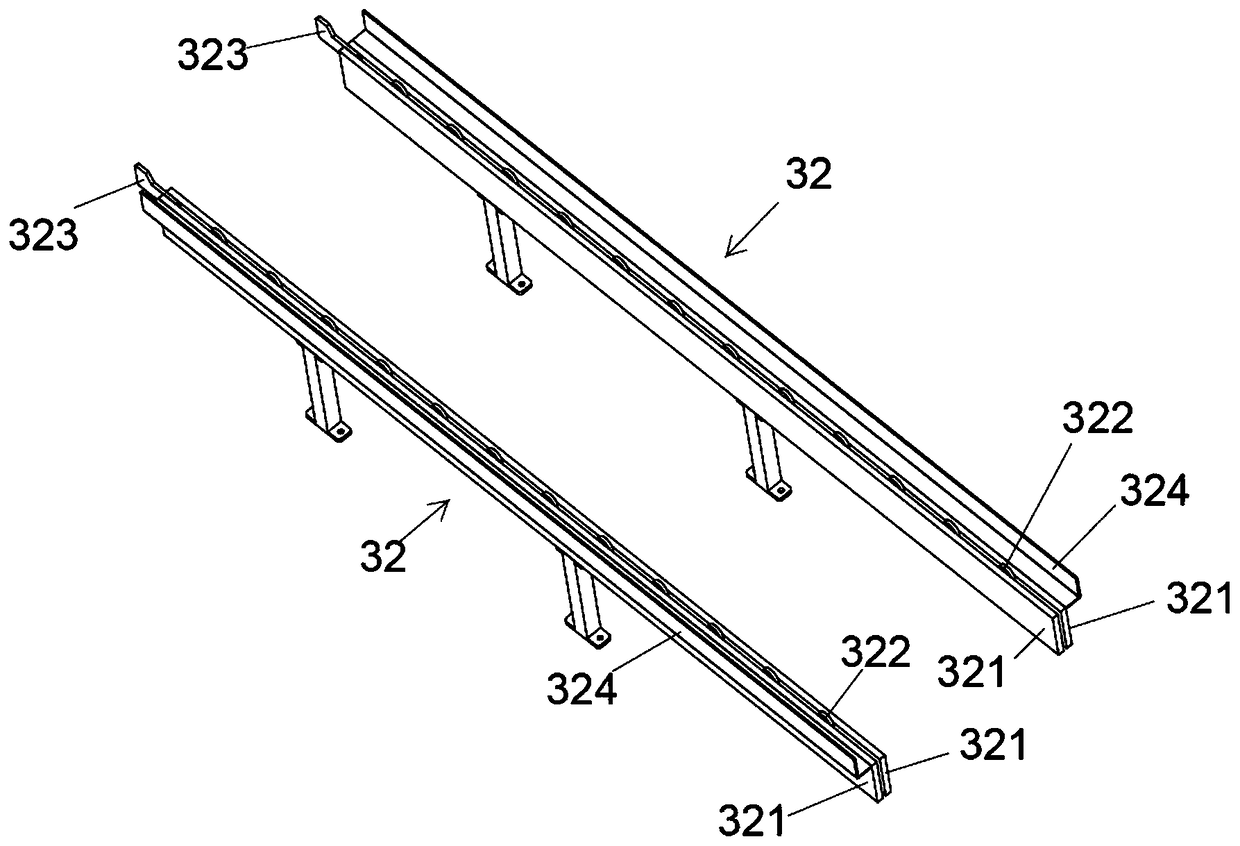

[0032] In the above-mentioned loading area, a loading manipulator 21 is provided, an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com