Feeding tray for precision gear hobbing machine

A technology of gear hobbing machines and feeding trays, which is applied in the field of gear hobbing machines, can solve the problems of poor versatility of feeding trays, the inability to place multiple shafts, the inability to adjust the number of material strips, and the number of workpieces. strong effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] In order to make the technical means, creative features, goals and effects achieved by the present invention easy to understand, the present invention will be further elaborated below in conjunction with illustrations and specific embodiments.

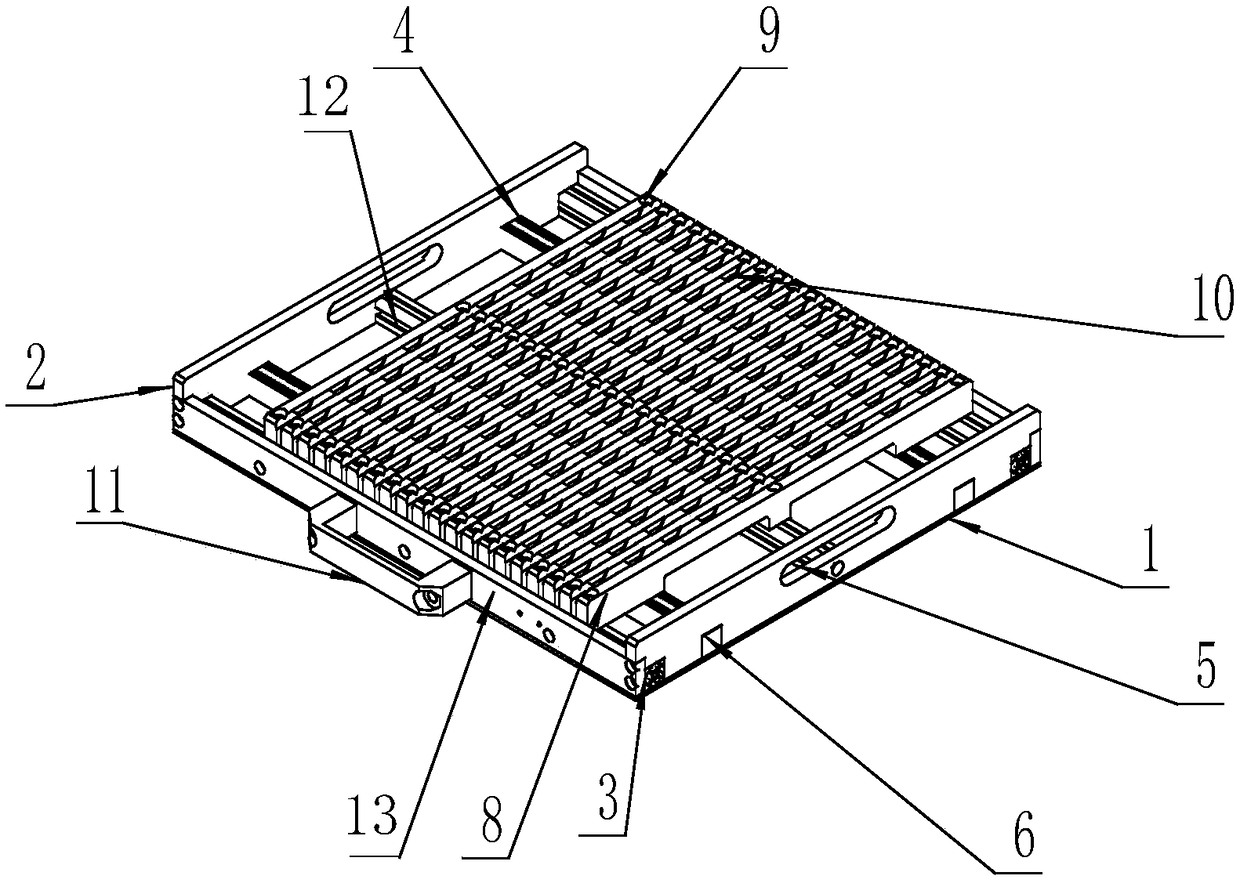

[0020] refer to figure 1 As shown, the feed tray for a precision hobbing machine includes a material box bottom plate 1, a trough and a support frame, and the material trough and the support frame are installed on the material box bottom plate 1, and the material box bottom plate 1 is provided with material Box edge protection 2, first trough adjustment seat 3, second trough adjustment seat 5, steel ruler 6, handle 11 and sidewall 13;

[0021] Described material box side protector 2 and material box bottom plate 1 are installed around material box bottom plate 1, material box side protector 2, material box side plate 13 and material box bottom plate 1 form a rectangular material box, and described material box side protector 2 i...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap