Q500qE high-strength bridge steel corner joint welding method

A welding method and high-strength technology, which is applied in the field of steel bridge manufacturing, can solve the problems of high-strength steel cold straightening, small deformation of plate units after welding, and affecting service fatigue life. The effect of high welding efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

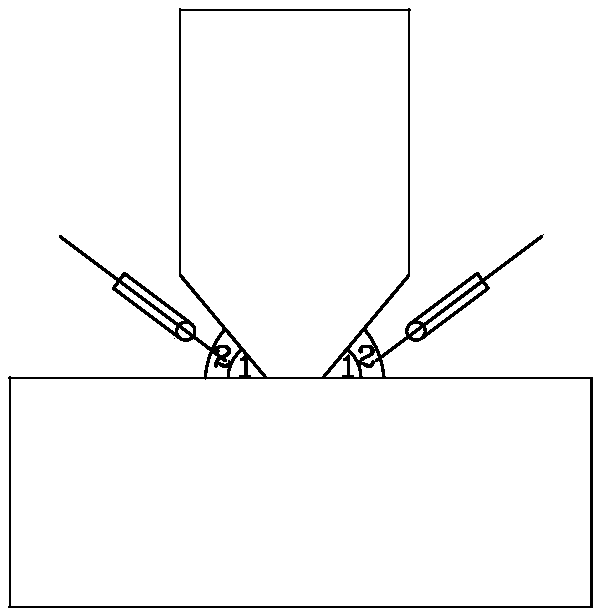

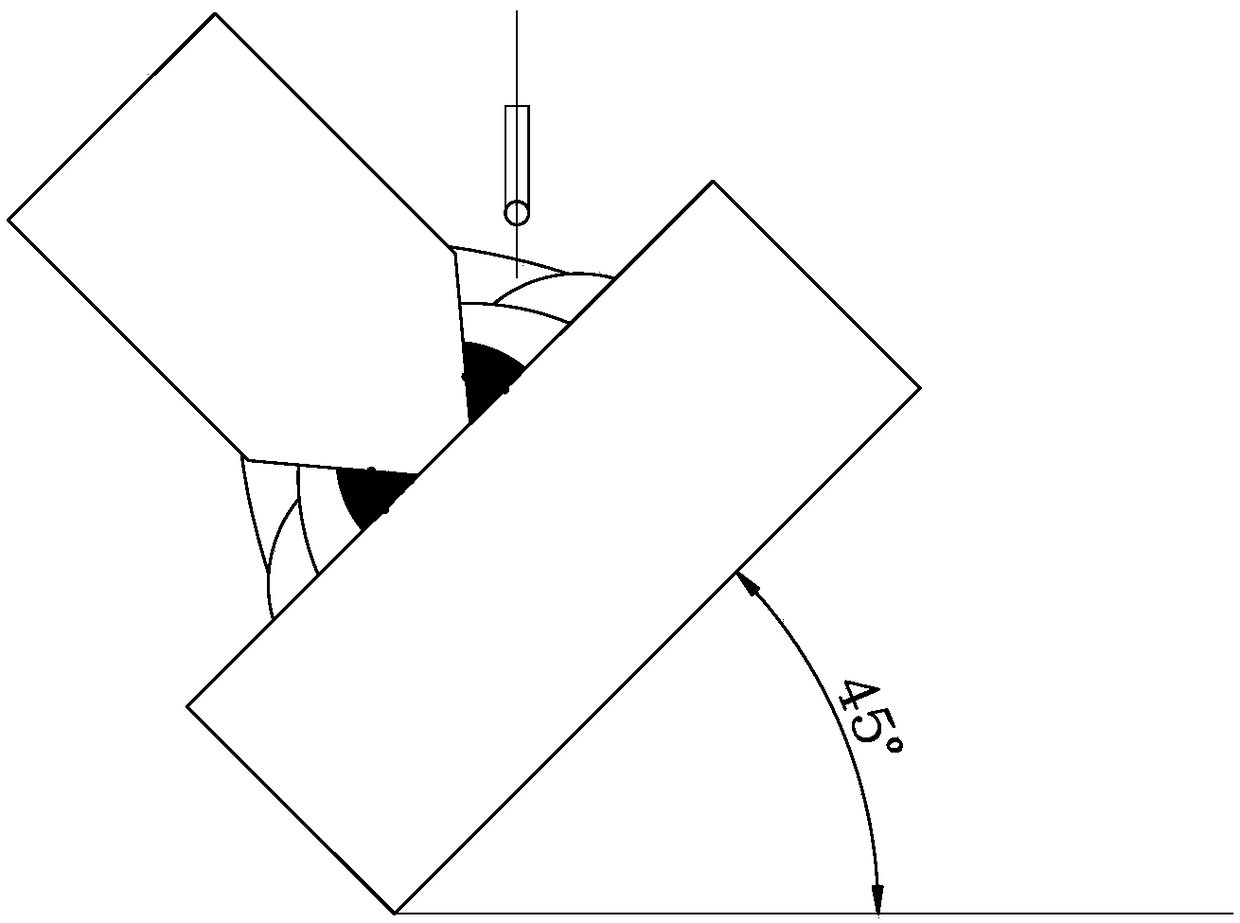

[0019] Attached below figure 1 , 2 , 3 and specific embodiments The present invention will be described in further detail.

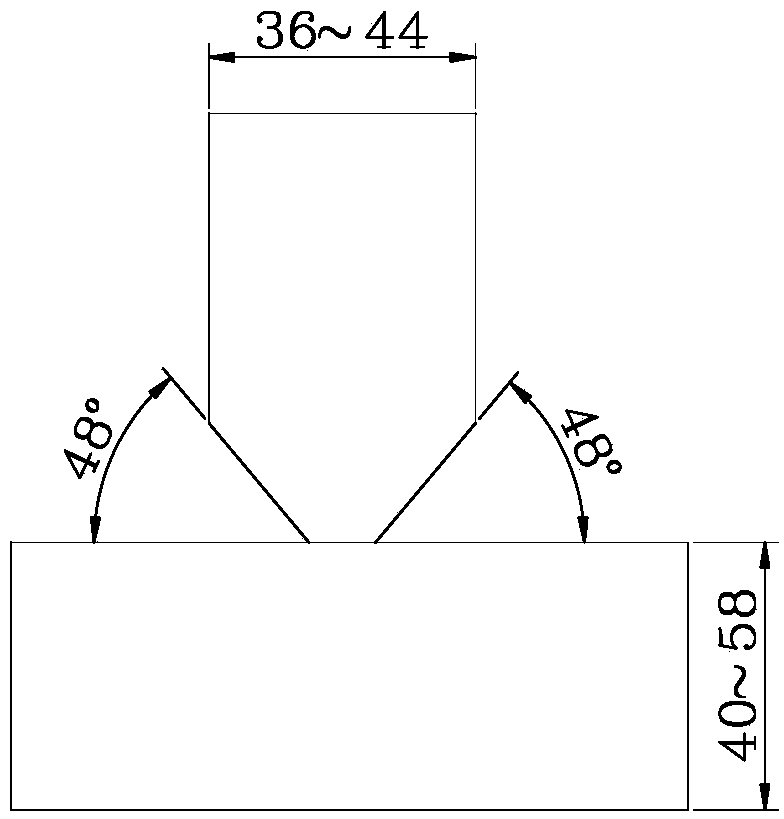

[0020] 1) Welding base metal: the thickness of the bottom plate is 40-58mm, and the thickness of the ribs (stiffeners) is 36-44mm; the bottom plate and the ribs are both Q500qE high-strength bridge steel, and their longitudinal and transverse tensile strengths are 659-730MPa , the longitudinal and transverse yield strengths are 528-573MPa, the elongation is 20.5%-26%, the low-temperature impact (-40°C) is 232-300J, and the shear section rate (-40°C) is 90%-100%;

[0021] 2) Welding groove: Partial penetration double-sided symmetrical grooves are opened on both sides of the ribs, and the groove angle is 48°. The double-sided groove angle of the existing partial penetration weld is 45° or 50°. When the 45° groove is used for welding, penetration is easy to occur, that is, incomplete fusion occurs at the weld root. 50° groove is used, because the plate i...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com