Cutting tool with embedded thin film temperature sensor and preparation method thereof

A temperature sensor, film temperature technology, applied in the field of cutting tools, to achieve the effect of good adhesion, high resolution and small size

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0049] A method for preparing a cutting tool with an embedded thin-film temperature sensor provided in an embodiment of the present invention includes the following steps:

[0050] S1 Prepare two cutter bodies, including the first cutter body and the second cutter body, which are ground, polished and cleaned for use;

[0051] S2 prepares a thin-film temperature sensor on the upper surface of the first cutter body, including the following sub-steps:

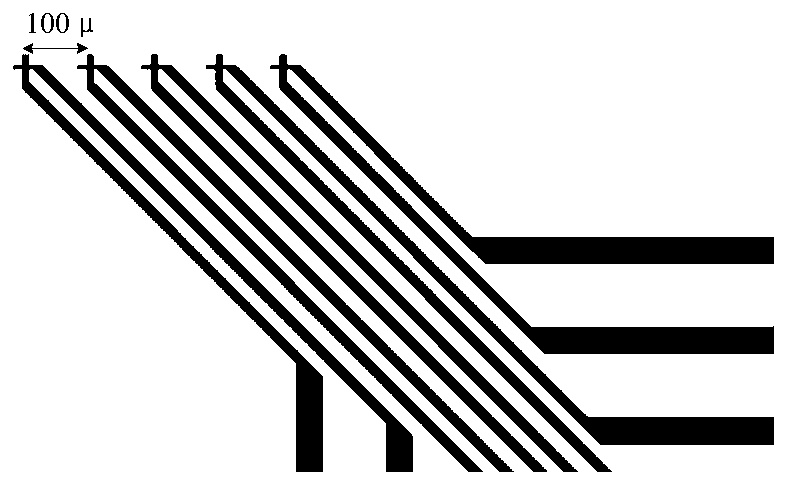

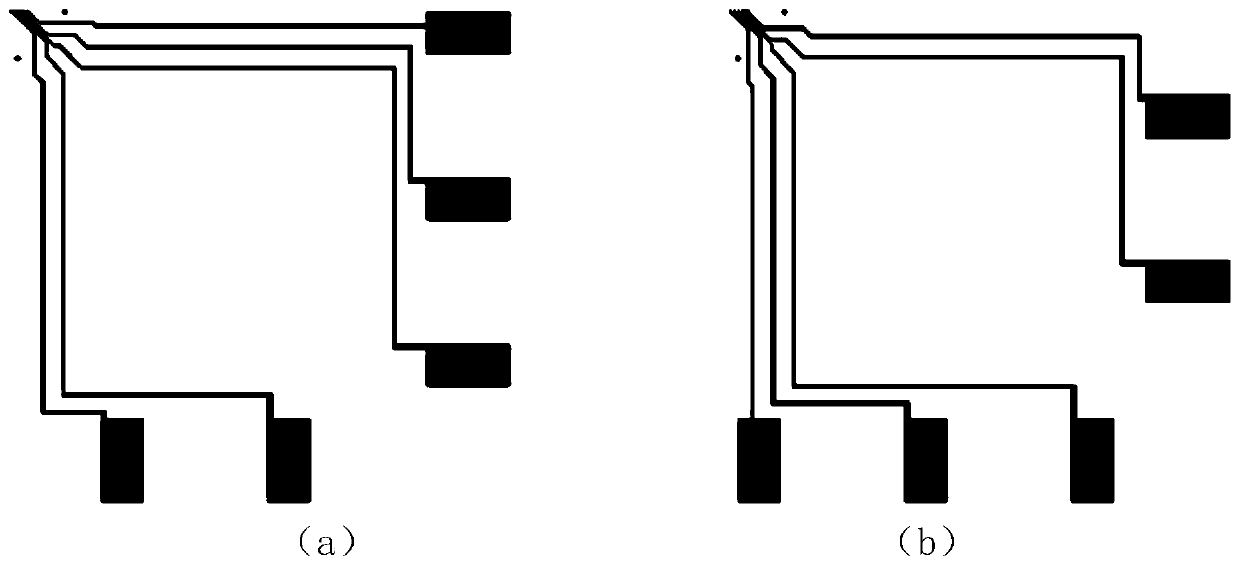

[0052] S21 preparing a temperature sensor mask, including the first part of the temperature sensor pattern and the second part of the temperature sensor pattern;

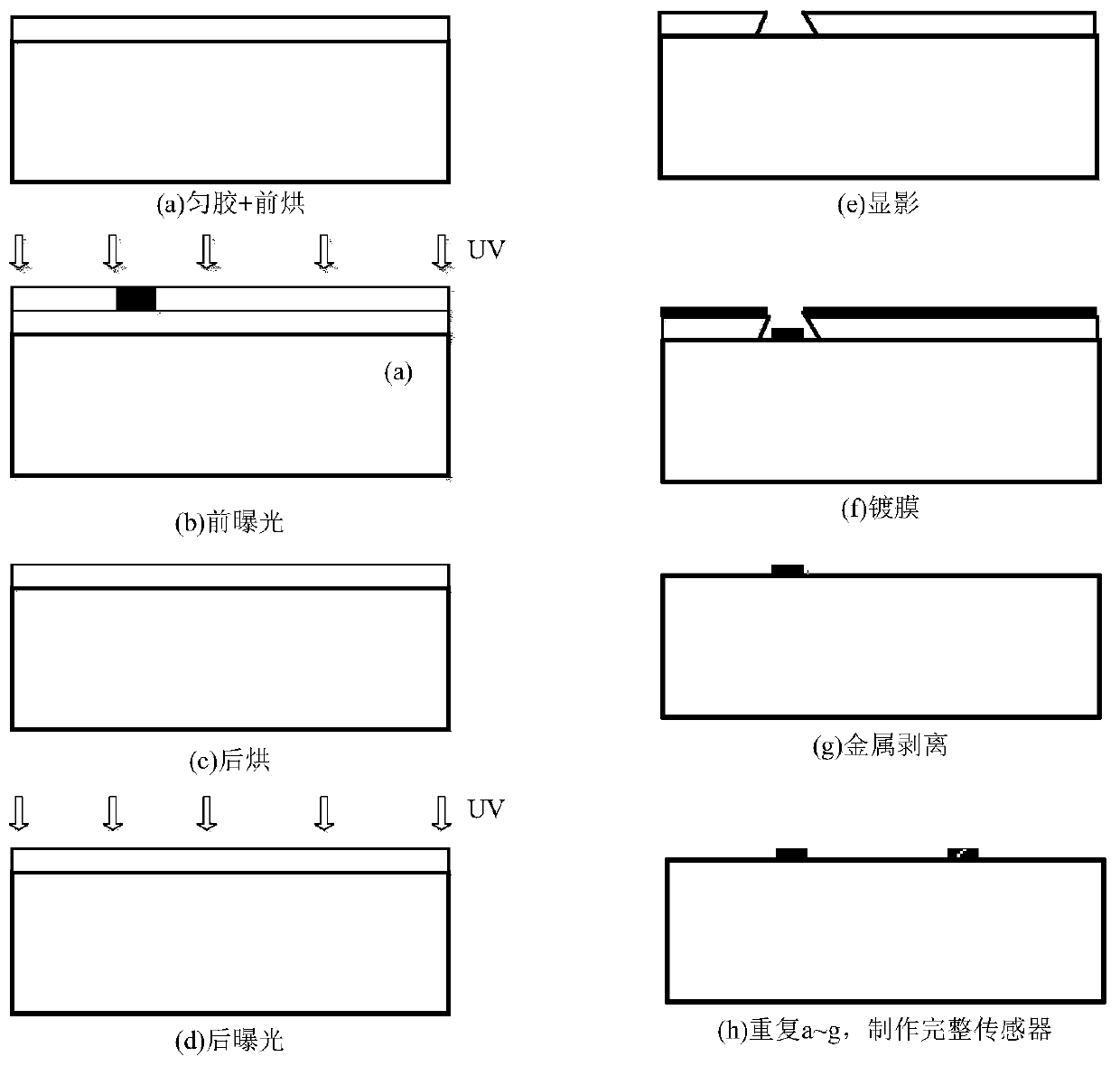

[0053] S22 Complete the preparation of the first part of the temperature sensor on the upper surface of the first cutter body through glue leveling, pre-baking, pre-exposure, post-baking, pan-exposure, development, coating and metal stripping, wherein the first part is W / Re26 (tungsten-rhenium 26 alloy , rhenium content 26%) alloy layer, as the negative pole of thermoc...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com