Formwork accessory for manufacturing pull rod sealing pit and formwork

A formwork and tie rod technology, applied in the field of building formwork and formwork, can solve the problems of damage to product quality, irregular pit edges, time-consuming and labor-intensive problems, and achieve the effects of low cost, neat edges and wide adaptability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

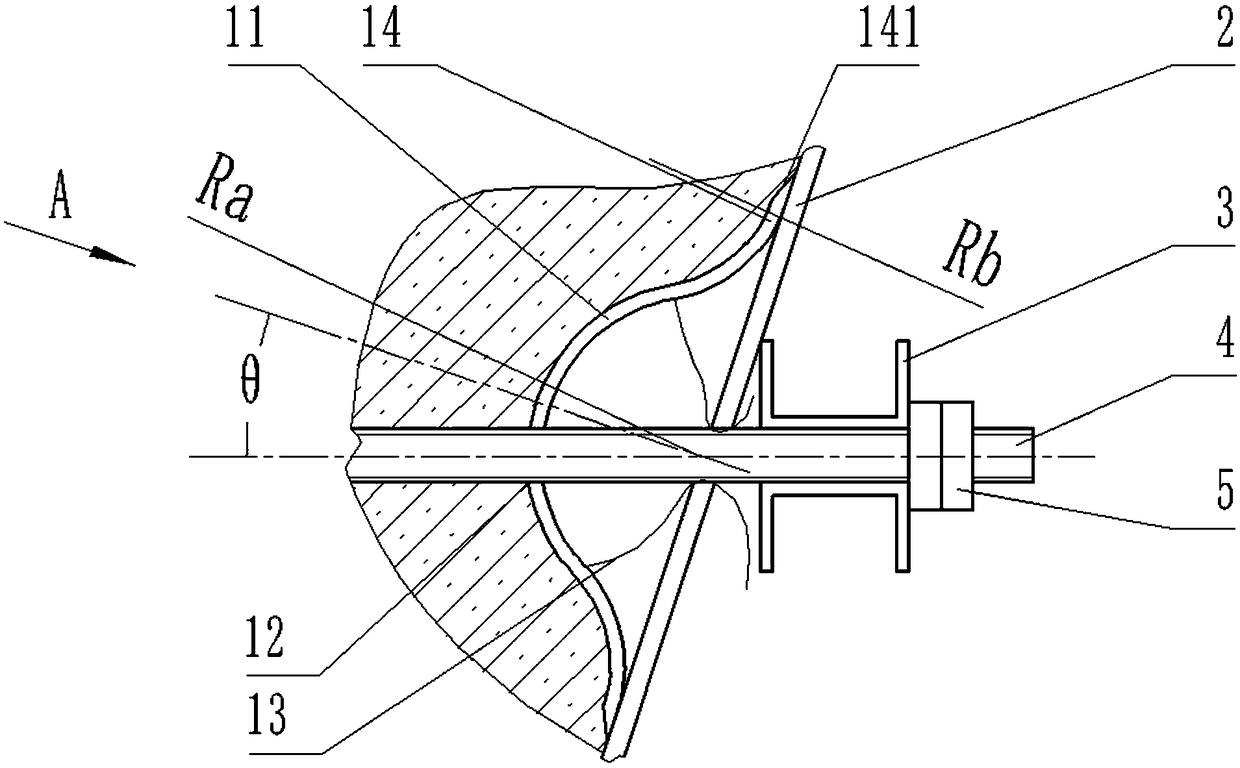

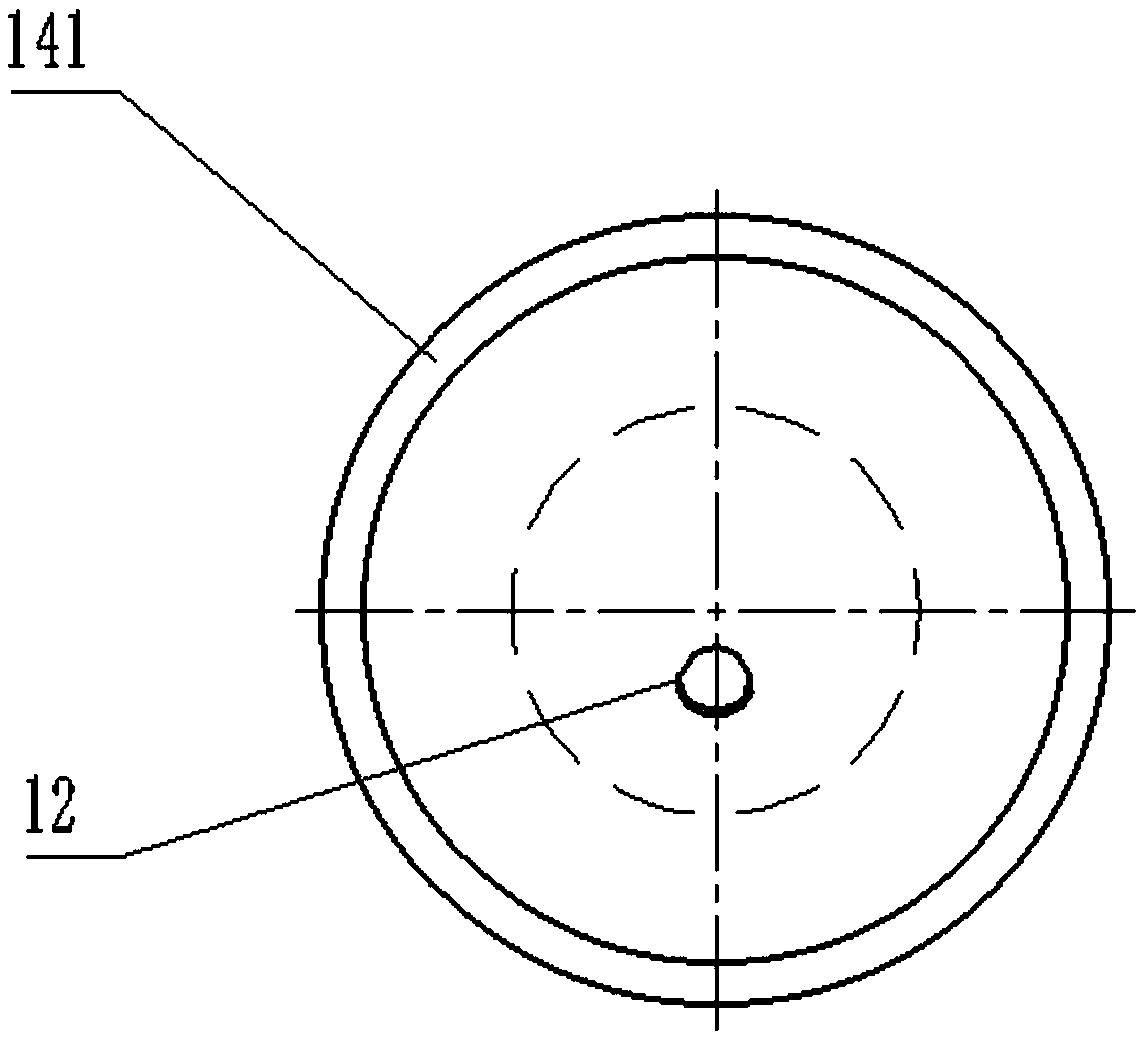

[0034] Such as figure 1 with figure 2 As shown, in the prior art, the tie rod 4 passes through the through hole of the tie rod on the template 2 and is tightened on the holder 3 using a lock nut 5. Symmetrically, the other end of the tie rod 4 is also arranged. This embodiment is set on the inner working surface of the existing template 2, including the cavity wall 11 and the sealing edge 14.

[0035] The convex surface of the cavity wall 11 is a spherical surface, the center of the sphere is located on the bonding surface of the sealing edge 14, and the radius Ra=15cm. The sealing edge 14 also includes a drafting bevel 141, and the drafting bevel 141 is integral with the convex surface of the cavity wall 11 without a negative drafting angle. This embodiment is suitable for removing the word concrete as a whole after solidification.

[0036] In fact, the convex surface can be square cone shape, arch shape, step shape suitable for angle grinders, etc.; it can also be circular co...

Embodiment 2

[0044] Such as figure 1 As shown, on the existing template 2, the template accessory 1 is welded. In this way, the template attachment 1 can be removed from the solidified concrete together during demolding, and a sealed pit is formed at the end of the tie rod.

[0045] After cutting the tie rod, use cement mortar to fill the sealing pit and smooth the outer surface.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com