Bearing radial through hole machining equipment

A technology of radial through holes and processing equipment, which is applied in metal processing equipment, drilling/drilling equipment, metal processing, etc., and can solve problems such as high personnel dependence.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

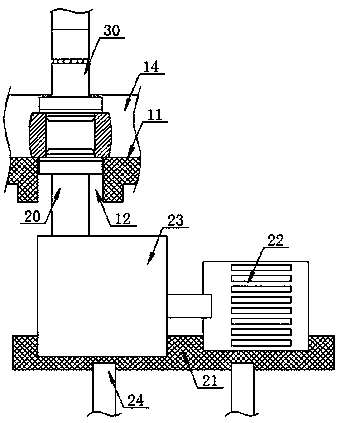

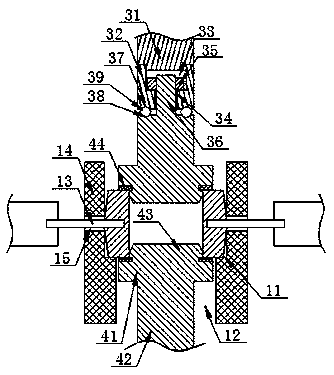

[0019] refer to Figure 1 to Figure 2 , Figure 1 to Figure 2 It is a structural schematic diagram of a specific embodiment of the present invention.

[0020] As shown in the figure, a bearing radial through hole processing equipment includes a bearing circulation platform for conveying bearing processed parts. The bearing circulation platform includes a platform support surface 11 arranged horizontally, and the platform support surface 11 is provided with Circular drilling station groove 12, the lower rotating clamping head 20 is arranged in the drilling station groove 12, and the upper rotating clamping head 30 is arranged directly above the drilling station groove 12. The axes of the upper rotary clamping head 30 and the lower rotary clamping head 20 are all vertical and collinearly arranged; a bearing drilling bit 13 for drilling the bearing is also included, and the axis of the bearing drilling bit 13 It is arranged horizontally, and the axis of the bearing drilling bit...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com