Machine vision automatic trolley

An automatic trolley and machine vision technology, which is applied to conveyors, conveyor objects, household appliances, etc., can solve problems such as soup spills, customers mistaken dishes, troubles, etc., and achieve the effect of preventing spills and preventing dishes from spilling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

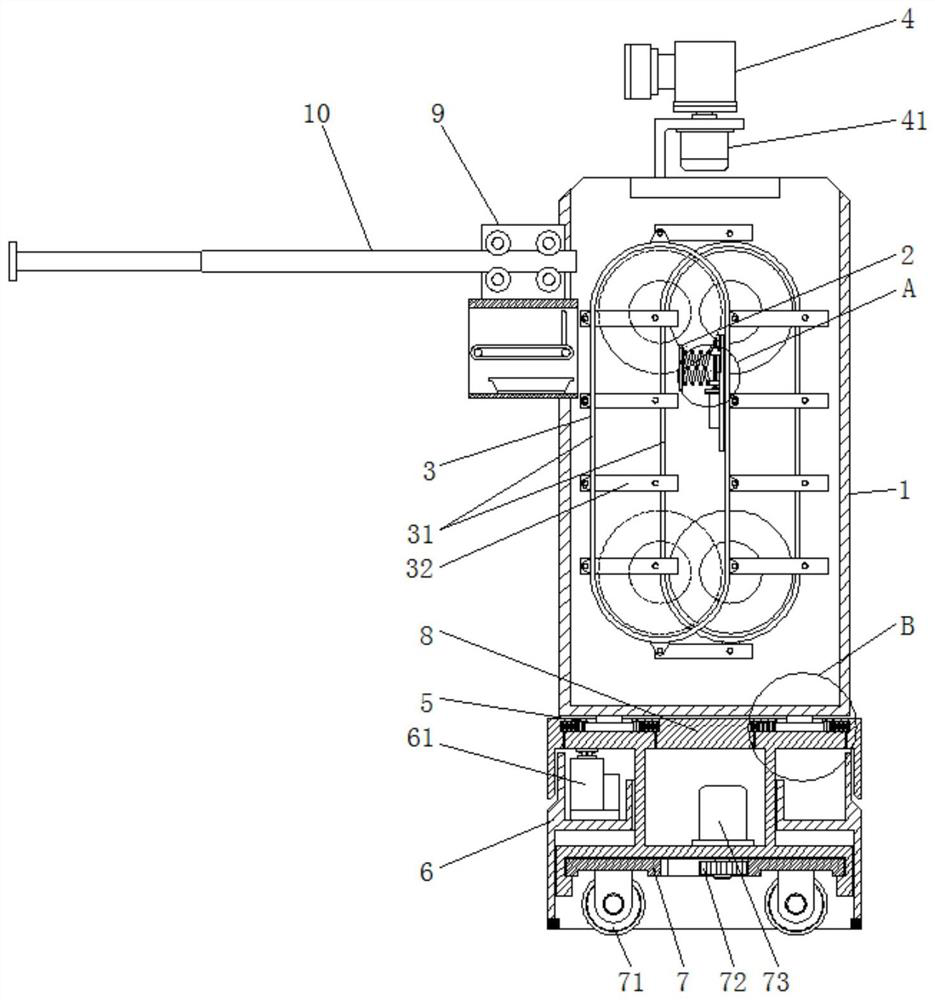

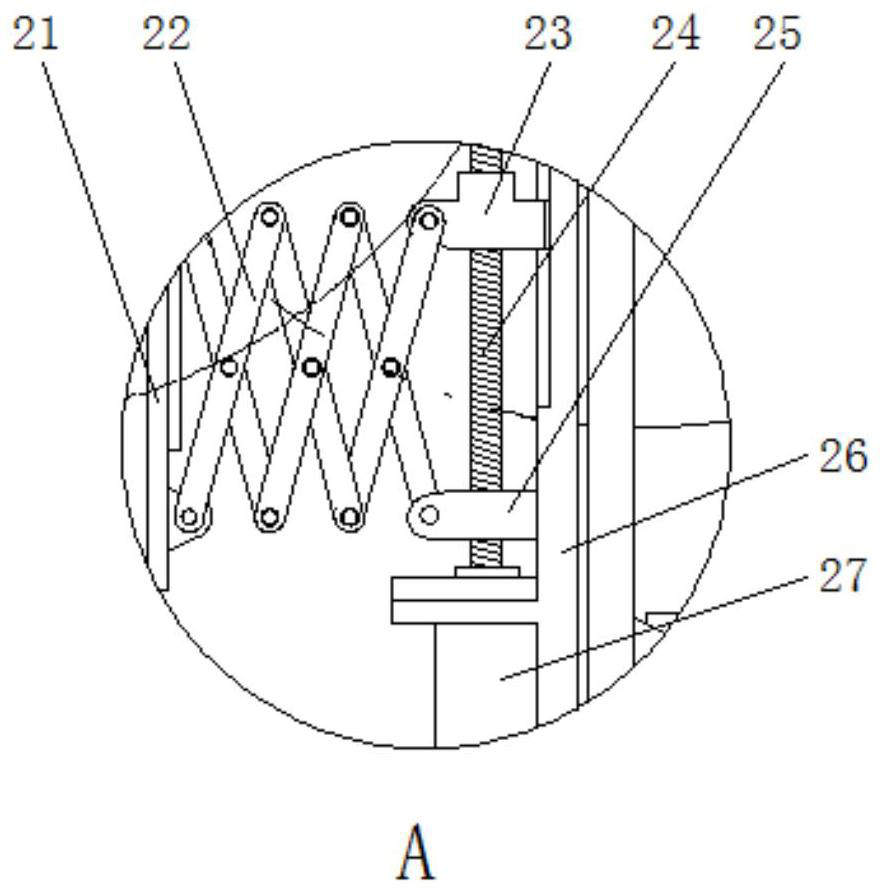

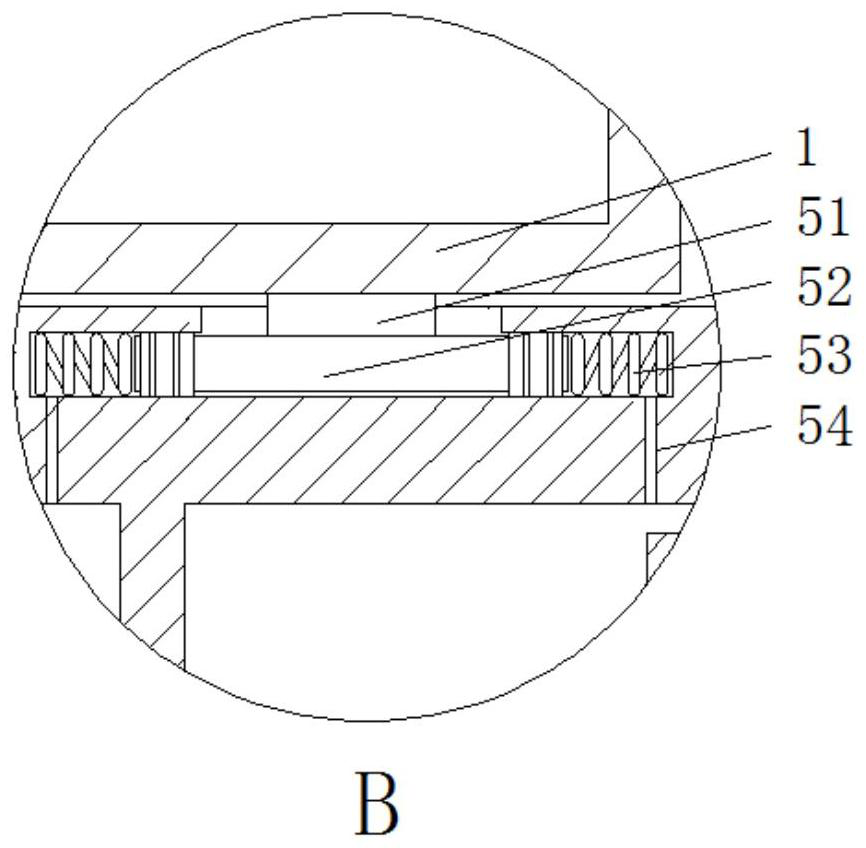

[0039] The present invention provides a kind of machine vision automatic trolley here through improvement, as Figure 1-Figure 10 As shown, a machine vision automatic trolley includes a frame 1 with a horizontal lifting mechanism 3 in the middle of the frame 1. The horizontal lifting mechanism 3 includes 2 chain belt conveyors 31, and the 2 chain belt conveyors 31 are asymmetrically arranged on the machine. On the both side walls of the frame 1, and between the two chain belt conveyors 31, several equidistantly distributed platens 32 are hinged, and a track frame 10 is arranged on the top of one side of the frame 1, and the track frame 10 is movably connected with Transmission mechanism 9, the position of transmission mechanism 9 corresponds to the position of platen 32, the bottom of frame 1 is connected with base 8 through emergency stop buffer mechanism 5, and the top of frame 1 is provided with vision sensor 4.

[0040] Through the mutual cooperation of the horizontal lift...

Embodiment 2

[0050] The present invention provides a kind of machine vision automatic trolley here through improvement, as Figure 1-Figure 10 As shown, a machine vision automatic trolley includes a frame 1 with a horizontal lifting mechanism 3 in the middle of the frame 1. The horizontal lifting mechanism 3 includes 2 chain belt conveyors 31, and the 2 chain belt conveyors 31 are asymmetrically arranged on the machine. On the both side walls of the frame 1, and between the two chain belt conveyors 31, several equidistantly distributed platens 32 are hinged, and a track frame 10 is arranged on the top of one side of the frame 1, and the track frame 10 is movably connected with Transmission mechanism 9, the position of transmission mechanism 9 corresponds to the position of platen 32, the bottom of frame 1 is connected with base 8 through emergency stop buffer mechanism 5, and the top of frame 1 is provided with vision sensor 4.

[0051] Through the mutual cooperation of the horizontal lift...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com