Building gravel cleaning and screening device

A screening device and construction technology, applied in packaging, sieving, separating solids from solids by air flow, etc., can solve the problems of increased transportation costs, single function of the device, inconsistent functions, etc., saving manpower and material resources, automation High degree, good cleaning effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

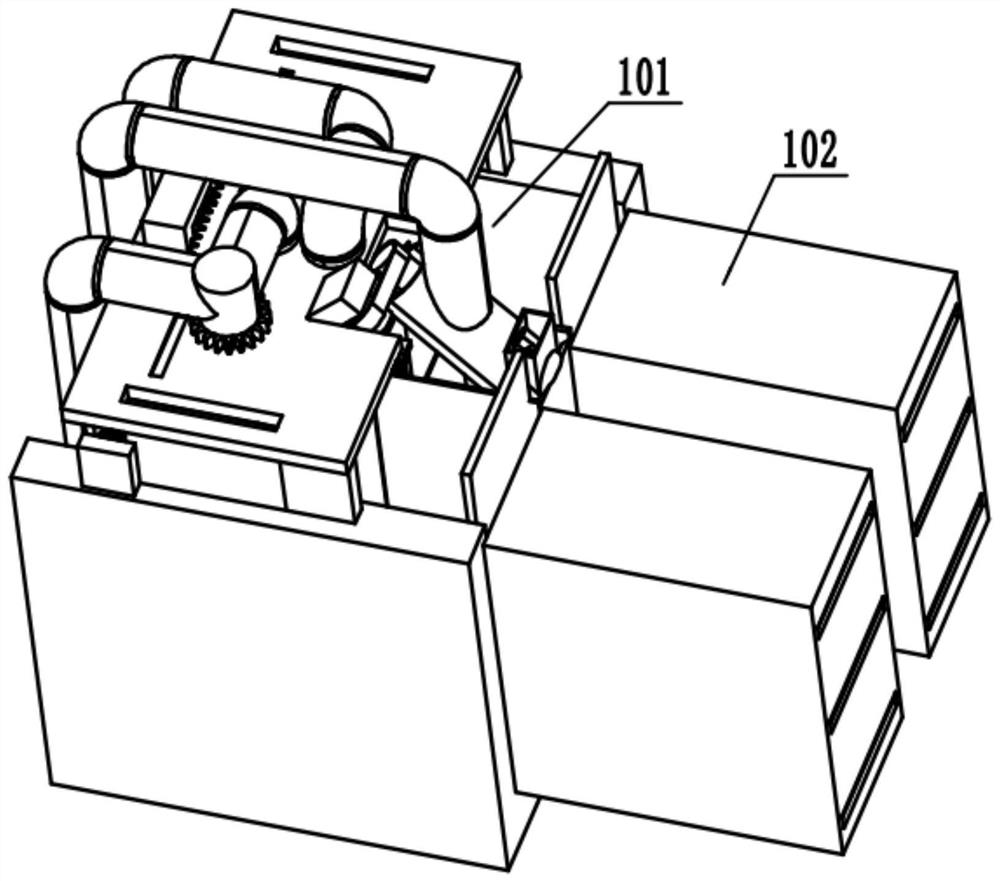

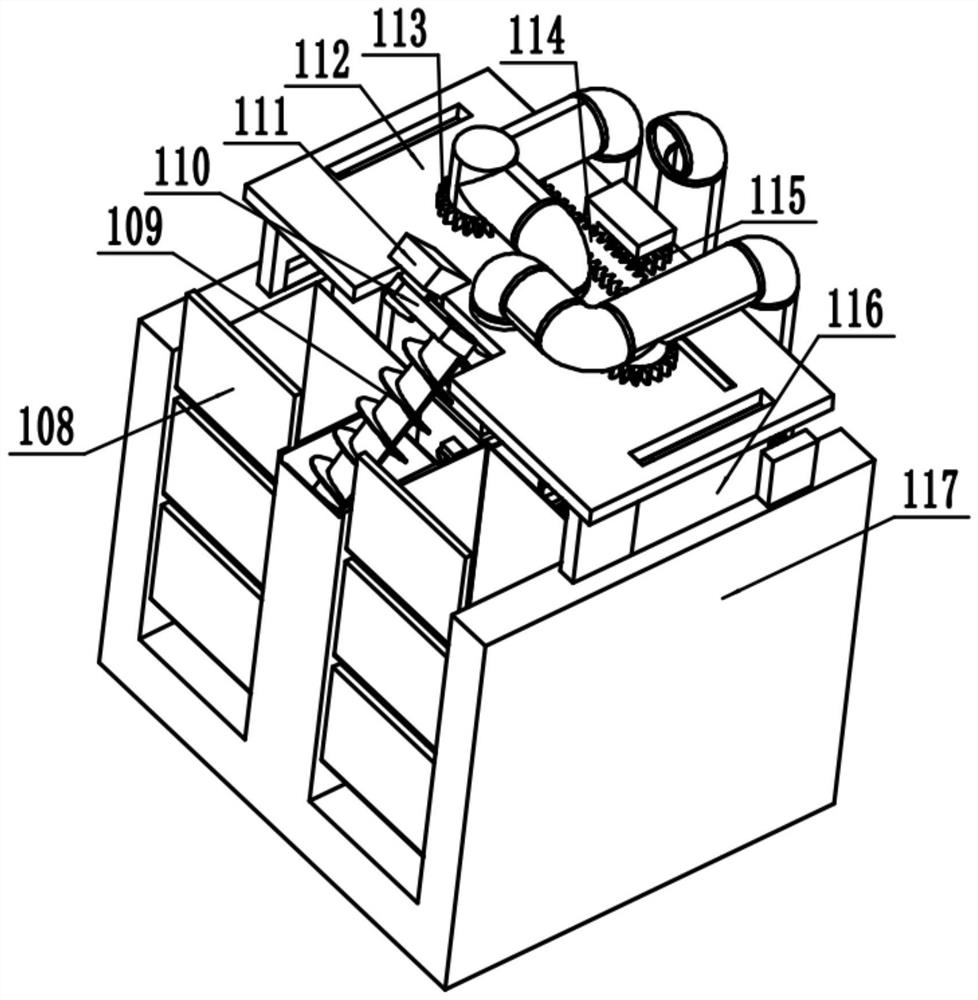

[0021] Example: such as figure 1 The shown sand cleaning and screening device for construction includes a primary screening assembly 101 and a secondary screening assembly 102. The primary screening assembly 101 is used for preliminary screening and cleaning of sand and gravel, and the secondary screening assembly 102 is used for cleaning For further screening of sand and gravel, the secondary screening assembly 102 is equipped with sieve plates with different sizes of screen holes, and multiple sieve plates reciprocate to classify the sand and gravel. The conveying plate 108 is driven by a motor and installed on a fixed stand. The plate 117 is used to transfer the sand on the sand storage box 122 to the secondary screening assembly 102.

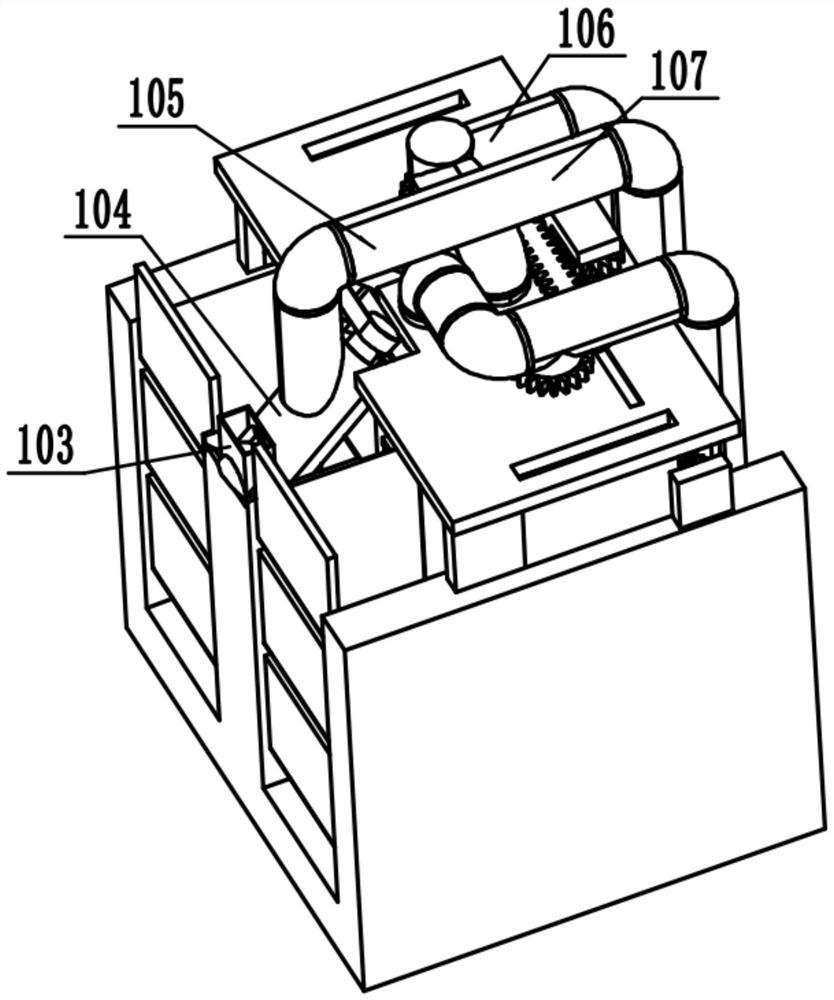

[0022] Such as figure 2 , image 3 , Figure 4 , Figure 5 The top of the shown primary screening assembly 101 is provided with a water pipe assembly 105, and the water pipe assembly 105 includes a double-head water pipe 106 and a singl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com