Tyre vulcanizing unit, tyre vulcanizing machine comprising tyre vulcanizing unit and vulcanizing process

A tire vulcanization and tire technology, which is applied in the field of vulcanizing machines, can solve the problems of high unevenness on the inner surface of the tire and affect the quality of the tire, and achieve the effects of reducing the overall height, improving production efficiency, and saving the use area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

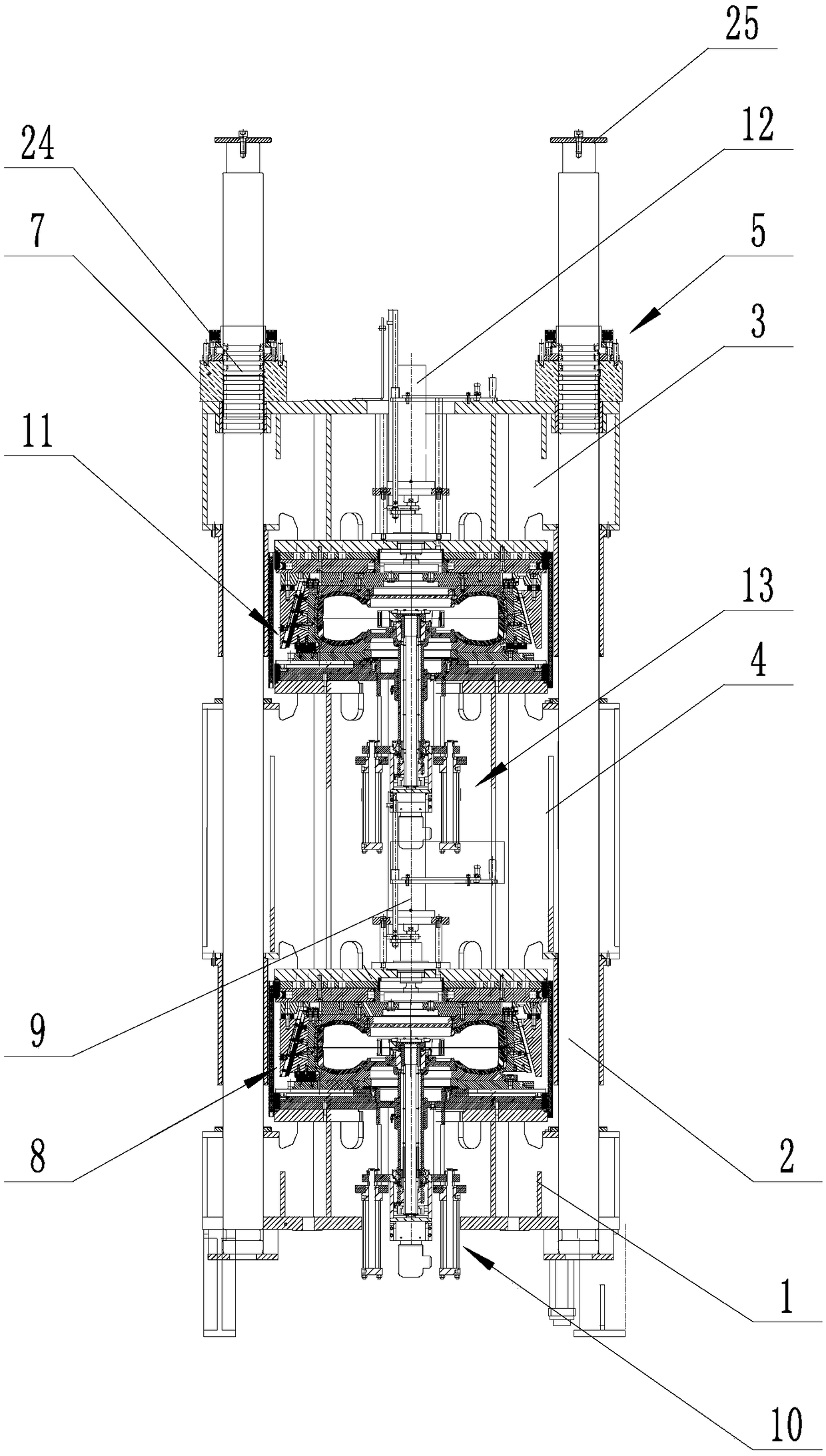

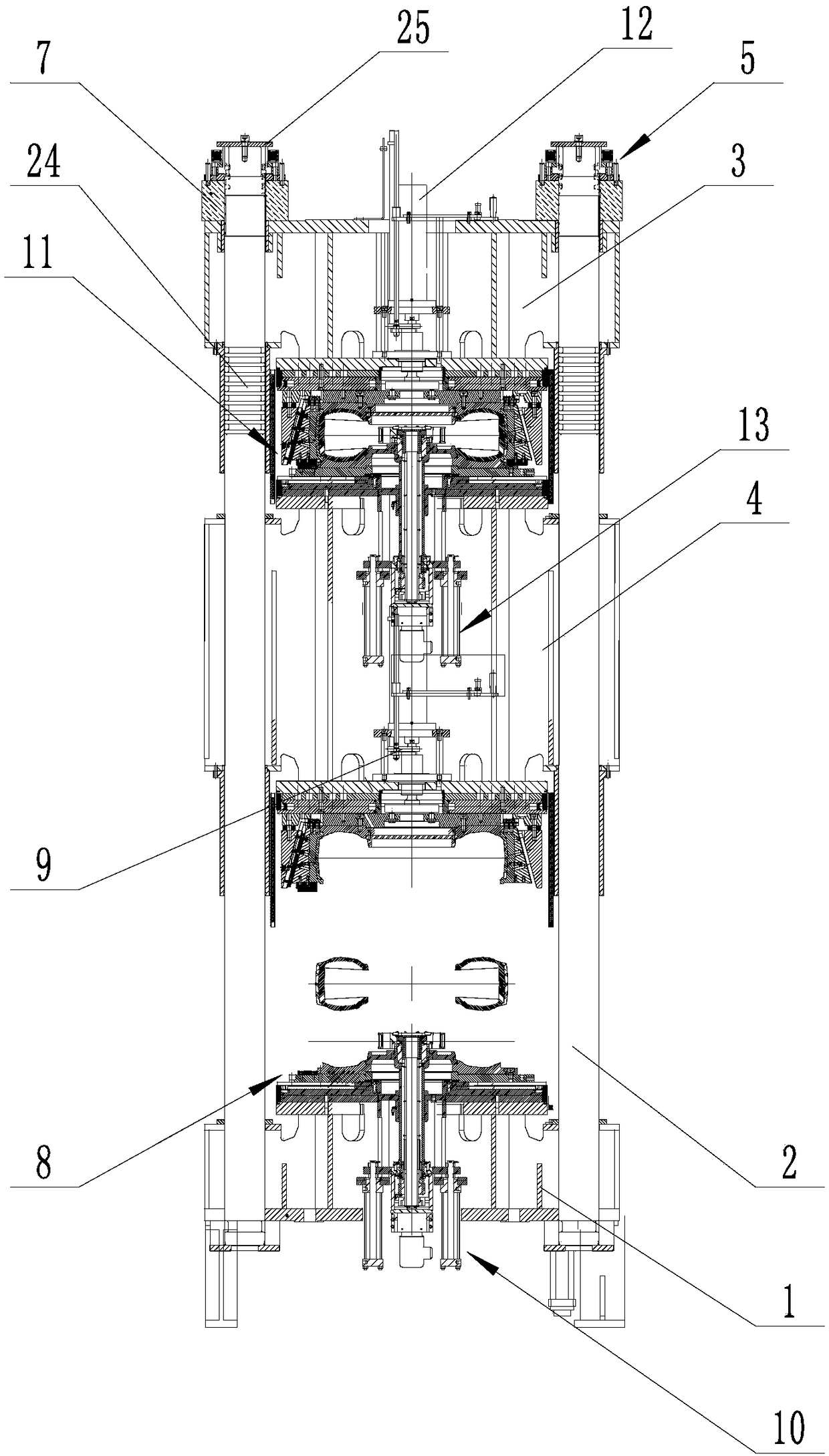

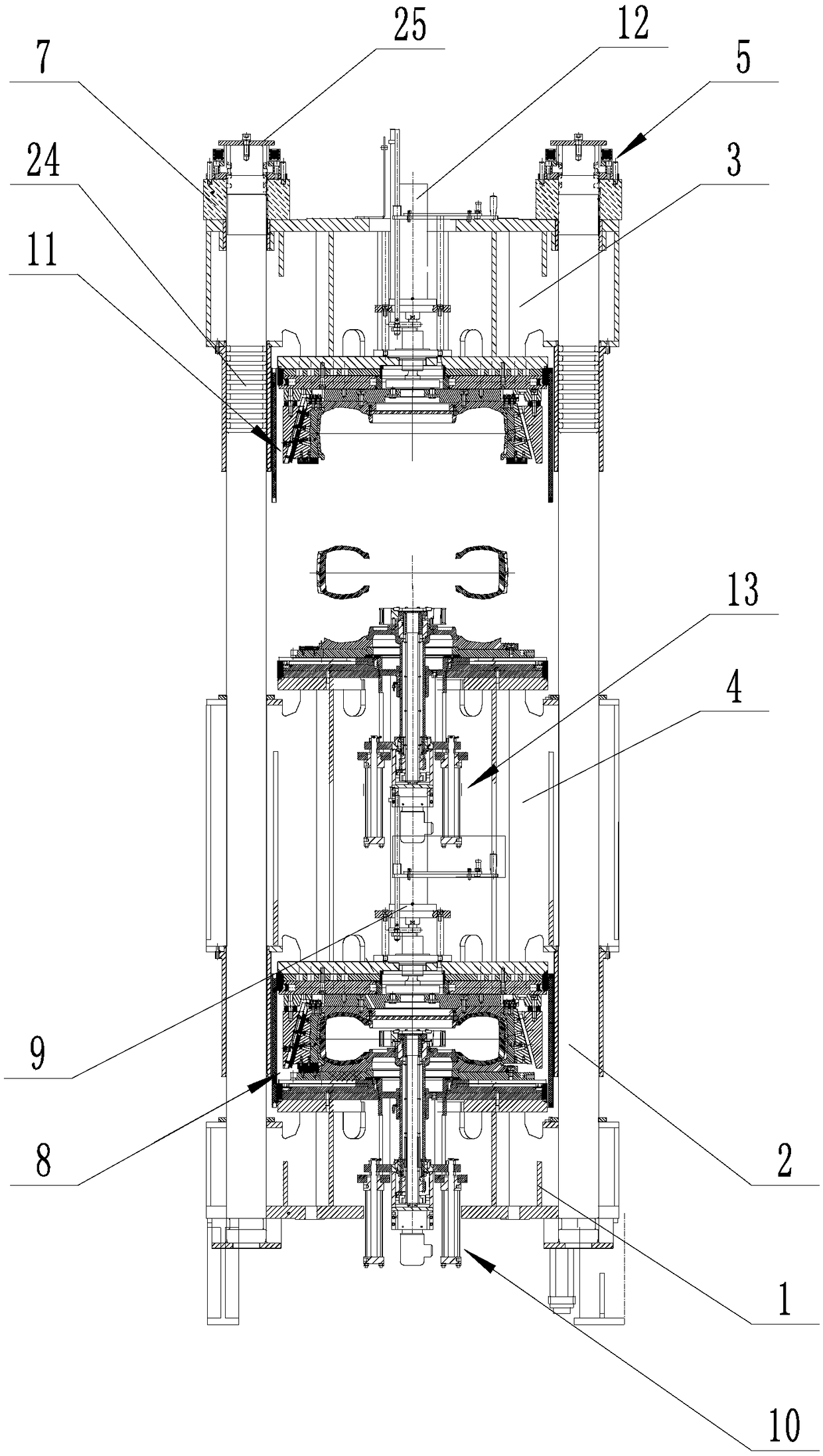

[0051] refer to Figure 1~3 , a tire vulcanization unit, including a base 1, and a guide column 2 fixedly connected to the base 1, the guide column 2 is connected with an upper movable beam 3 and a middle movable beam 4 from top to bottom, and the upper movable beam 3 There is a locking mechanism 5 for limiting the movement of the upper movable beam 3 along the guide column, and the upper movable beam 3 and the middle movable beam 4 are provided with a locking mechanism 5 for driving the upper movable beam 3 and the middle movable beam 4 to move along the guide column. The guide column 2 moves up and down the mold opening and closing cylinder group 6, the first movable mold assembly for vulcanizing tires is connected between the middle movable beam 4 and the base 1, the upper movable beam 3 and the middle movable beam 4 A second active mold assembly for vulcanizing tires is connected between them; an afterburner cylinder 7 for pressing down the first active mold assembly and t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com