Glass tube fixture, glass tube clamping ventilation head and vertical glass tube bulb-blowing machine

A technology of glass tube and bubble blowing machine, which is applied in glass forming, glass reshaping, glass manufacturing equipment, etc. It can solve the problems of clamping and sealing of glass tubes without using the principle of extrusion, and achieves convenient installation and disassembly as well as Replacement and maintenance, fewer parts used, and lower cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

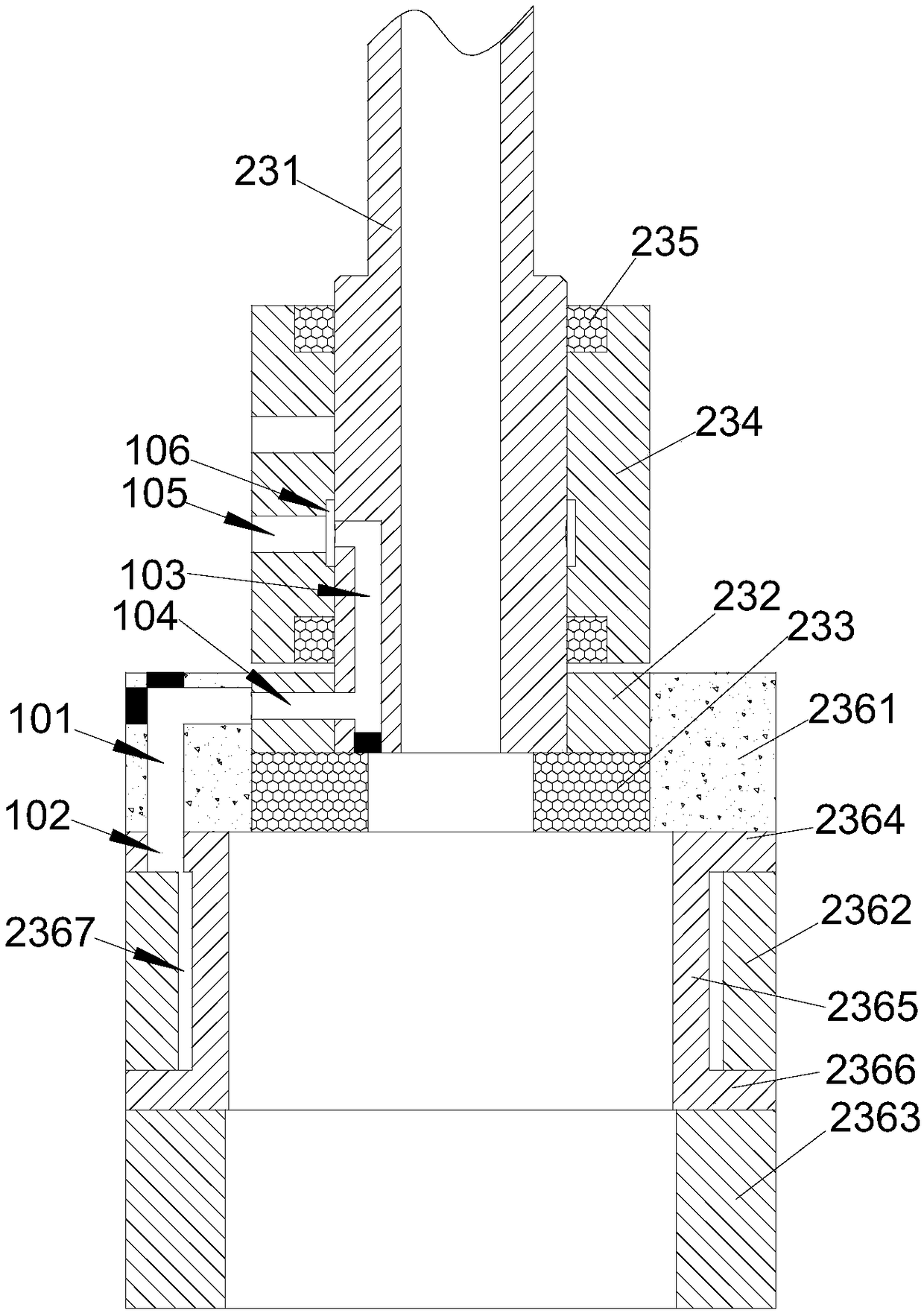

[0035] In this embodiment, a glass tube clamp is used to solve the problem of clamps that do not use extrusion to clamp the glass tube in the prior art, including an insertion barrel and an extrusion component, and the extrusion component is installed on the insertion barrel. When in use, the glass tube is inserted into the socket, and the extrusion part squeezes the glass tube so that the glass tube is pressed tightly in the socket. The structure is ingenious, and the parts are used less, which is more convenient for installation, disassembly, replacement and maintenance. , the cost is lower.

[0036] As a specific implementation of this embodiment, the extruding part in this embodiment can be an inflatable and deflated air bag, which is connected to the inner ring wall of the socket by screw locking or bonding. When it is pressed, it will squeeze the glass tube so that it is compressed into the socket.

[0037] As a best implementation mode of this embodiment, the inserting...

Embodiment 2

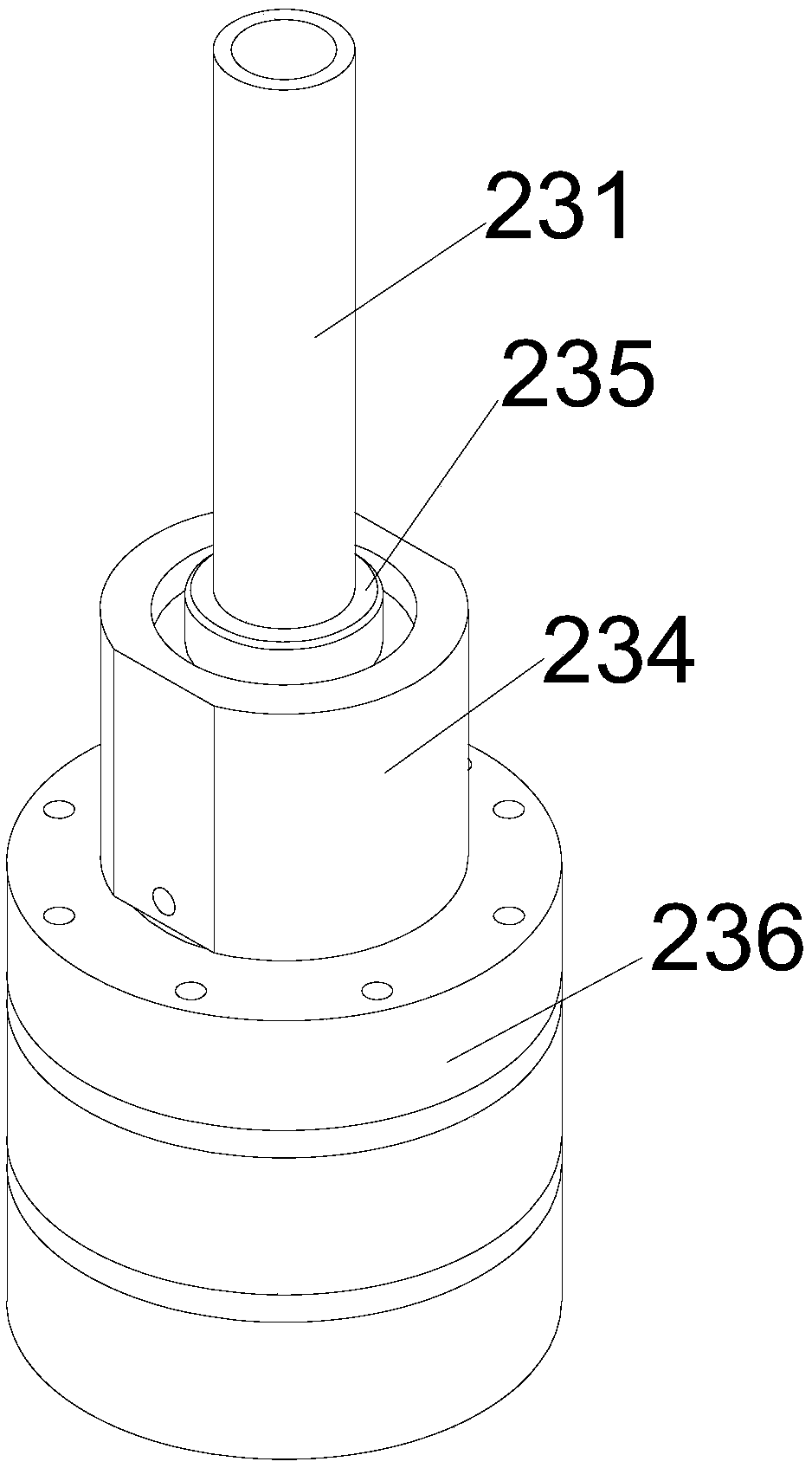

[0040] In this embodiment, a glass tube clamping ventilator head includes an air blowing pipe, an annular connecting flange A and the glass tube fixture in Embodiment 1, the main body of the above air blowing pipe is a straight pipe, and one end of the air blowing pipe is provided with a thickened structure A thickened end is formed, and the above-mentioned A ring-shaped connecting flange is coaxially arranged on the thickened end of the air blowing pipe. A fourth air channel is arranged on the wall body.

[0041] The inner wall of the upper cylinder of the above-mentioned glass tube fixture is provided with a B ring-shaped connecting flange coaxial with the upper cylinder and compatible with the above-mentioned A ring-shaped connecting flange. When installing, insert the above-mentioned A ring-shaped connecting flange into the above-mentioned upper cylinder and connect it to the above-mentioned B ring-shaped connecting flange through B screws. The inside of the glass tube cl...

Embodiment 3

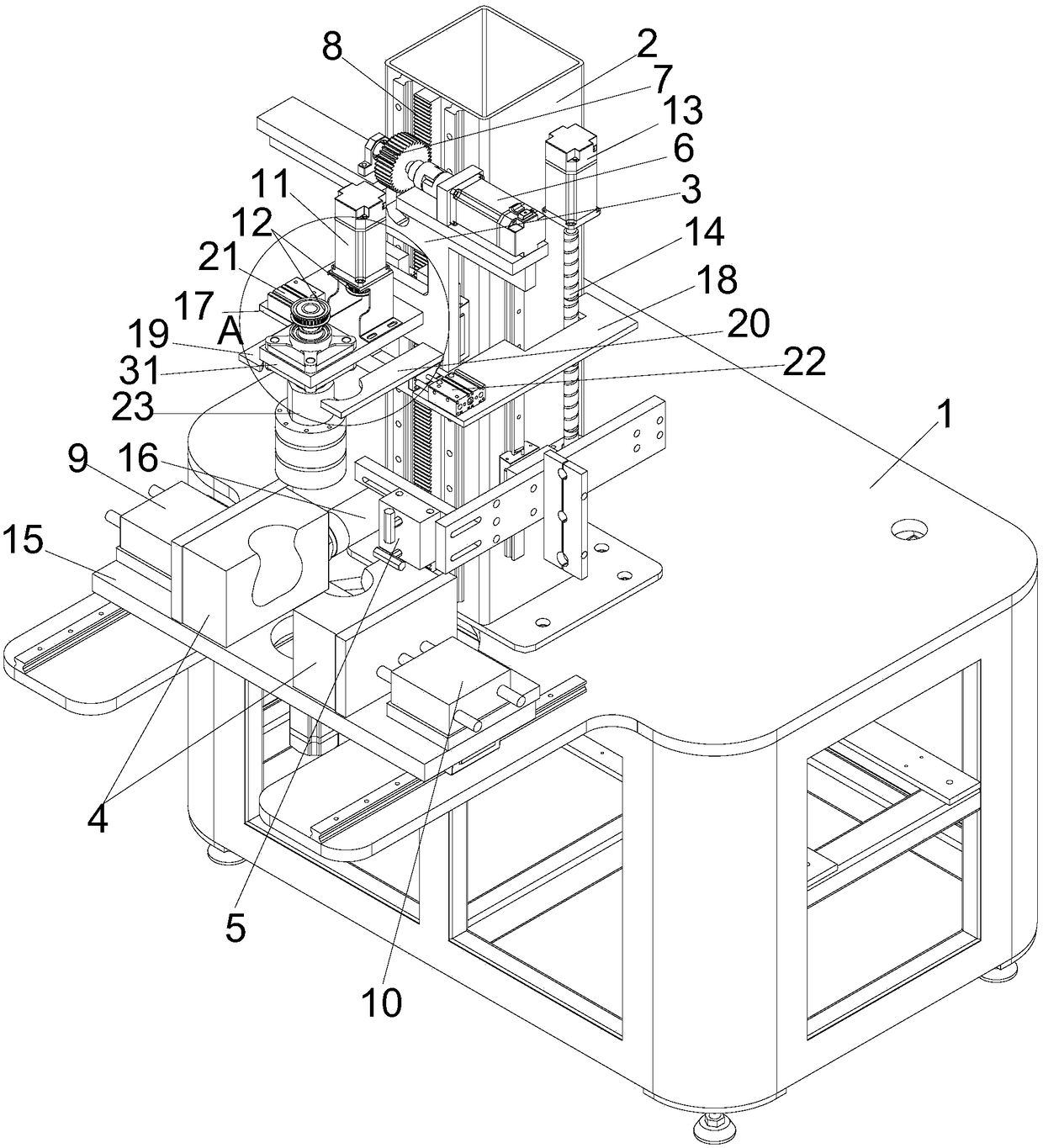

[0046] In this embodiment, a vertical glass tube bubble blowing machine includes a base, a column, a bracket, the glass tube clamping ventilator head in Embodiment 2, a mold and a flamethrower. The above-mentioned base is roughly in a frame structure, and the above-mentioned column is The strip-shaped square frame structure, the above-mentioned column is vertically installed on the upper end surface of the above-mentioned base.

[0047] The above-mentioned bracket is installed on the above-mentioned upright post by sliding up and down by the C guide rail slider pair, and a first driving part for driving the bracket to move up and down on the upright post is installed between the above-mentioned bracket and the upright post. Specifically, the guide rail of the above-mentioned C guide rail slider pair is vertically installed on the front side wall of the column, the slider of the C guide rail slider pair is installed on the above-mentioned bracket, and the above-mentioned first d...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com